NaN3@BNNTs (boron nitride nanotubes) confinement nanometer compound material and preparation method thereof

A nanocomposite material and confinement technology, applied in the field of NaN3@BNNTs confinement nanocomposite materials and their preparation, can solve problems such as unstable characteristics and achieve the effect of solving the problem of safe storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides the NaN described in the technical solution 3 The preparation method of @BNNTs confinement nanocomposite comprises the following steps:

[0028] (1) providing an aqueous dispersion of sodium azide and boron nitride nanotubes;

[0029] (2) The aqueous dispersion obtained in the step (1) is subjected to freeze-drying, washing and natural drying successively to obtain NaN 3 @BNNTs confined nanocomposites.

[0030] The invention provides an aqueous dispersion of sodium azide and boron nitride nanotubes. In the present invention, the mass of boron nitride nanotubes and sodium azide in the aqueous dispersion is preferably 1:7 to 8, more preferably 1:7.2; the concentration of sodium azide in the aqueous dispersion is Preferably it is 28%-29.6%, more preferably 29.6%. When the concentration of sodium azide is preferably 29.6%, the sodium azide reaches a saturated state in the aqueous dispersion.

[0031] In the present invention, the prep...

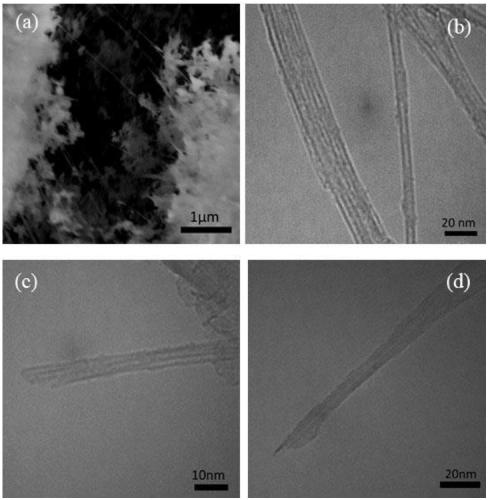

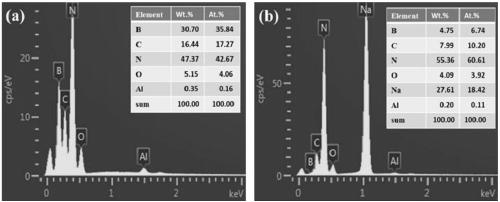

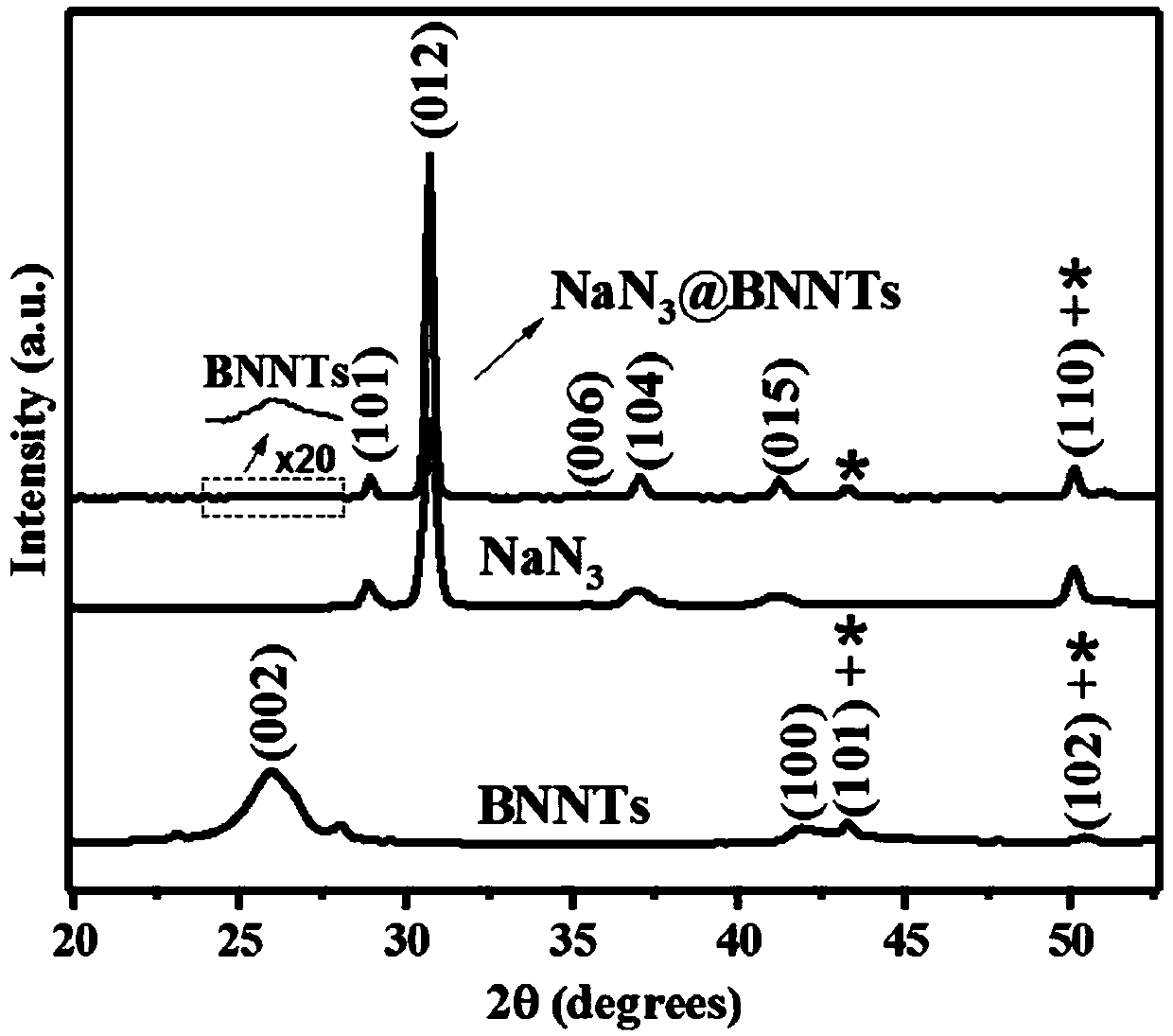

Embodiment 1

[0038] Dissolve excess sodium azide solid powder in deionized water, stir magnetically for 30 min, and take the supernatant after standing to obtain a saturated sodium azide aqueous solution. Add 0.03 g of boron nitride nanotubes into 0.5 mL of saturated sodium azide aqueous solution, and vibrate ultrasonically for 2 h to obtain a stable and uniform suspension. The suspension obtained by ultrasonic treatment was subjected to freeze-drying treatment for 72 h by using freeze-drying technology. Collect the freeze-dried product, place it on wet filter paper (wetting with deionized water) and wash it with water for 3 to 5 times to remove most of the sodium azide attached to the surface of the boron nitride nanotube, and then wash the The sample was dried naturally for 48 hours to obtain NaN 3 @BNNTs confined nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com