An ultra-high pressure open channel disc tube reverse osmosis membrane module

A technology of disc-type reverse osmosis and reverse osmosis membranes, which is applied in the field of ultra-high pressure open channel disc-type reverse osmosis membrane components, which can solve the problems of O-ring scouring and displacement, long welding time of single-piece membrane bags, pressure The container is easy to rust and other problems, to achieve the effect of preventing erosion and displacement, avoiding uneven weld seam, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

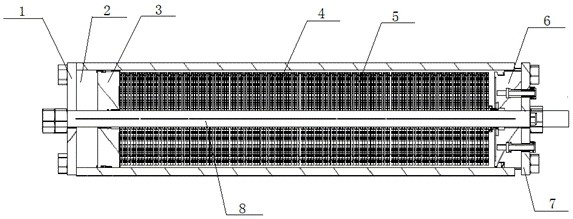

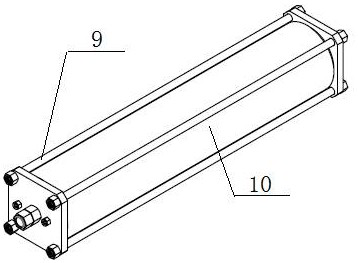

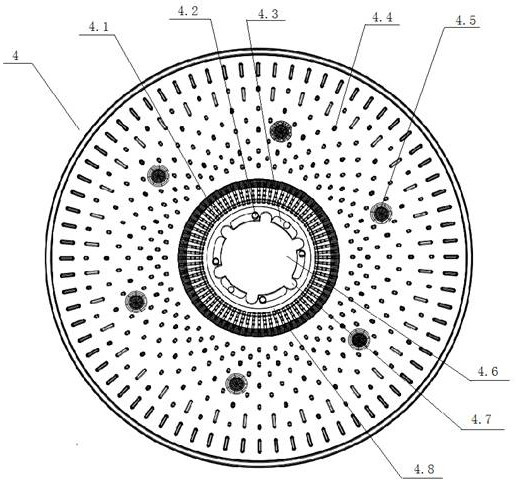

[0027] Such as figure 1 As shown, an ultra-high pressure open flow channel disc-type reverse osmosis membrane module in this embodiment includes a membrane shell 10 made of glass fiber material with a thickness of 16 mm, a central tie rod 8 arranged in the membrane shell 10, and a guide plate 4 and the membrane bag 5, the deflector plate 4 and the membrane bag 5 are stacked in turn to form a reverse osmosis membrane. The shaft sleeve, the upper end flange 3 and the supporting terminal flange 2, the lower end flange 6 is set on the central tie rod 8 located under the reverse osmosis membrane, and the upper support plate 1 and the lower support plate 7 are set at the upper and lower ends of the membrane shell 10, There are also four vertically placed pressure-bearing tie rods 9 on the outside of the membrane shell 10, and the two ends of the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com