Polyester protective film for cellphones and preparation method thereof

A protective film and polyurethane technology, applied in the field of polyurethane protective film for mobile phones and its preparation, can solve the problems of brittleness, poor light transmittance, easy aging, etc., and achieve the effects of strong chemical stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

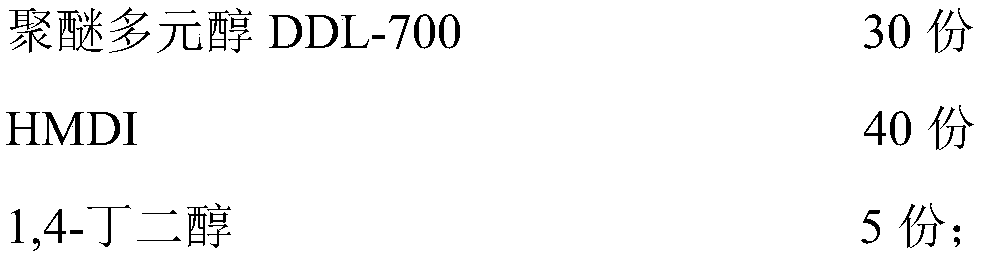

[0033] The polyurethane protective film for mobile phones is made of the following raw materials in parts by mass:

[0034]

[0035]

[0036] Among them: Zibo Dexin Federal Chemical Industry Co., Ltd. is the manufacturer of polyether polyol DDL-1000D and polyether polyol DDL-700.

[0037] The preparation method is as follows:

[0038] (1) Mix the measured polyether polyol DDL-1000D and polyether polyol DDL-700 evenly and vacuum dehydrate at 100°C for 1.5 hours;

[0039] (2) Add metered HMDI after cooling to 50° C., and heat up to 75° C. to synthesize a prepolymer with an NCO content of 4 wt %;

[0040] (3) After cooling down to 55°C, add 1,4-butanediol to the prepolymer obtained in step (2) and mix evenly, then pour it into the mold and vulcanize for 30 minutes before demoulding;

[0041] (4) Then, vulcanize at 80° C. for 10 hours to obtain a polyurethane protective film for mobile phones with a thickness of 0.15 mm.

Embodiment 2

[0043] The polyurethane protective film for mobile phones is made of the following raw materials in parts by mass:

[0044]

[0045] Among them: Zibo Dexin Federal Chemical Industry Co., Ltd. is the manufacturer of polyether polyol DDL-1000D and polyether polyol DDL-700.

[0046] The preparation method is as follows:

[0047] (1) Mix the measured polyether polyol DDL-1000D and polyether polyol DDL-700 evenly and vacuum dehydrate at 110°C for 2.0 hours;

[0048] (2) Add metered HMDI after cooling to 50° C., and heat up to 80° C. to synthesize a prepolymer with an NCO content of 5 wt %;

[0049] (3) After cooling down to 55°C, add 1,4-butanediol and ethylene glycol to the prepolymer obtained in step (2) and mix evenly, then pour it into the mold and vulcanize for 30 minutes before demoulding;

[0050] (4) Then, vulcanize at 80° C. for 11 hours to obtain a polyurethane protective film for mobile phones with a thickness of 0.15 mm.

Embodiment 3

[0052] The polyurethane protective film for mobile phones is made of the following raw materials in parts by mass:

[0053]

[0054]

[0055] Among them: Zibo Dexin Federal Chemical Industry Co., Ltd. is the manufacturer of polyether polyol DDL-1000D and polyether polyol DDL-700.

[0056] The preparation method is as follows:

[0057] (1) Mix the measured polyether polyol DDL-1000D and polyether polyol DDL-700 evenly and vacuum dehydrate at 120°C for 1.5 hours;

[0058] (2) Add metered HMDI after cooling down to 45°C, and heat up to 70°C to synthesize a prepolymer with an NCO content of 3.5wt%;

[0059] (3) After cooling down to 55°C, add 1,3-propanediol to the prepolymer obtained in step (2) and mix evenly, then pour it into the mold and vulcanize for 30 minutes before demoulding;

[0060] (4) Then, vulcanize at 90° C. for 12 hours to obtain a polyurethane protective film for mobile phones with a thickness of 0.15 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com