Suction anchor uplift bearing capacity dynamically testing device and method

A technology of uplift bearing capacity and dynamic testing, which is applied in the test of basic structure, construction, basic structure engineering, etc. It can solve the influence of the discrete form of the result accuracy structure, the best mooring point and the best loading angle are not discussed, etc. problem, to achieve the effect of increasing the test range, wide application range and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

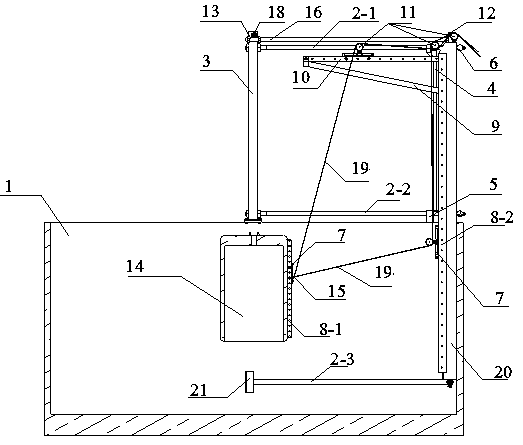

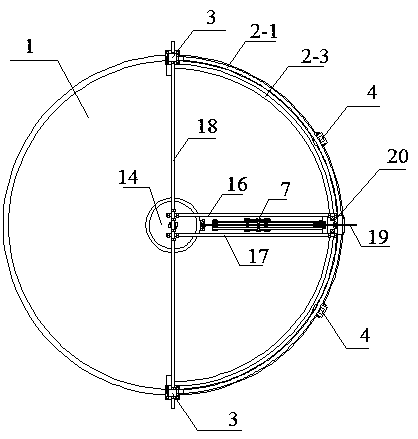

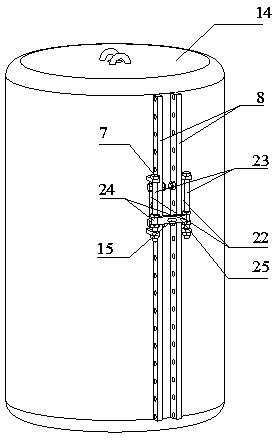

[0057] Such as Figure 1~15 As shown, a test device for dynamically testing the pull-out bearing capacity of a suction anchor includes a model box 1, a column, a suction anchor 14, a guide plate, an arc-shaped guide rail and a horizontal limit device;

[0058] The model box 1 is a steel cylinder, and the model box 1 is filled with model soil and water, and the suction anchor 14 is buried in the middle of the soil in the model box 1;

[0059] The top of the model box 1 is connected with uprights. There are four uprights in total, including two side uprights 3 and two middle uprights 4. The four uprights are evenly distributed on one side of the semicircle at the top of the model box 1. The bottom of the side uprights 3 Connect with the wall of the model box 1 through the backing plate, insert the bottom of the center column 4 into the base of the center column 5 on the top of the model box, and fasten through the bolts;

[0060] The suction anchor 14 is located at the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com