Hard rock intelligent frequency conversion electric drive raise boring machine

A technology for raising drilling rigs and variable frequency motors, applied to rotary drilling rigs, drill pipes, drill pipes, etc., which can solve problems such as inconvenience and increased risks, and achieve the effect of intelligent frequency conversion and reducing personnel workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

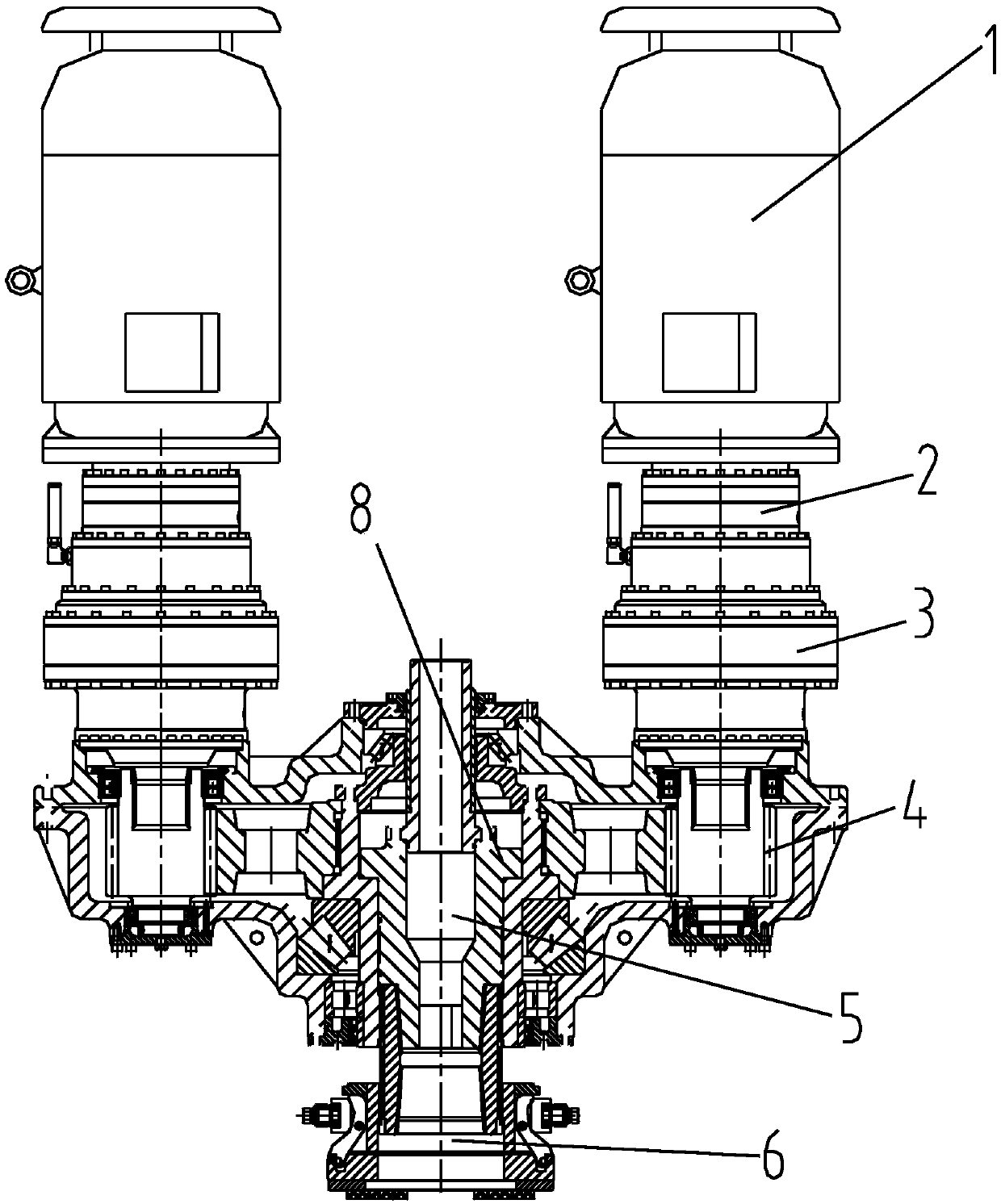

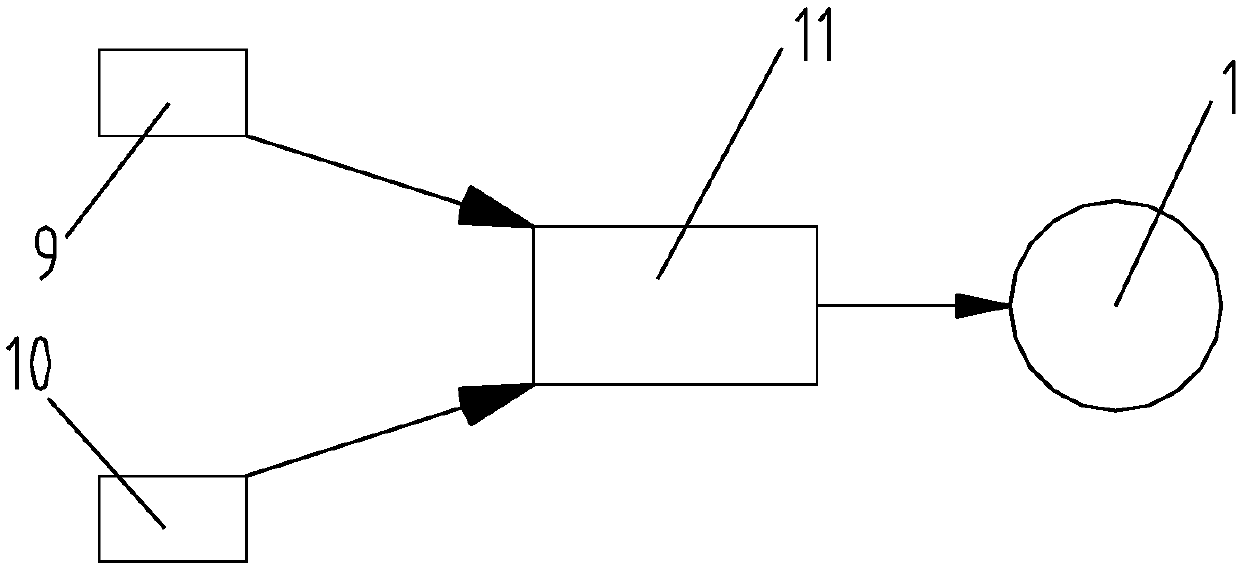

[0016] like figure 1 As shown, the extremely hard rock intelligent frequency conversion electric drive raise drilling rig in this embodiment includes an electric drive transmission system and an intelligent control system. The intelligent control system transmits control signals to the electric drive transmission system, and the electric drive transmission system performs transmission according to the control signals. . The electric drive transmission system includes a variable frequency motor 1, a hydraulic torque converter 2, a planetary gearbox 3, a gear box 4 and a power head 8; The power input end is driven and connected, the power output end of the hydraulic torque converter 2 is connected with the power input end of the planetary gearbox 3, and the power output end of the planetary gearbox 3 is connected to the power of the gearbox 4. The input end is drivingly connected; the power output end of the gearbox 4 is drivingly connected to the power input end of the power h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com