High-voltage power transmission line construction stringing early warning method based on precise positioning

A high-voltage transmission line, precise positioning technology, applied in the direction of tension measurement, instruments, measuring devices, etc., can solve problems such as misjudgment, stress value changes at the line release, asynchronous stress value changes at the tight line, and disconnection accidents, etc., to achieve Effects of reducing human errors, increasing safety factors, and preventing disconnection accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose of the present invention, technical solutions and advantages clearer, the detailed description of the present invention is carried out below:

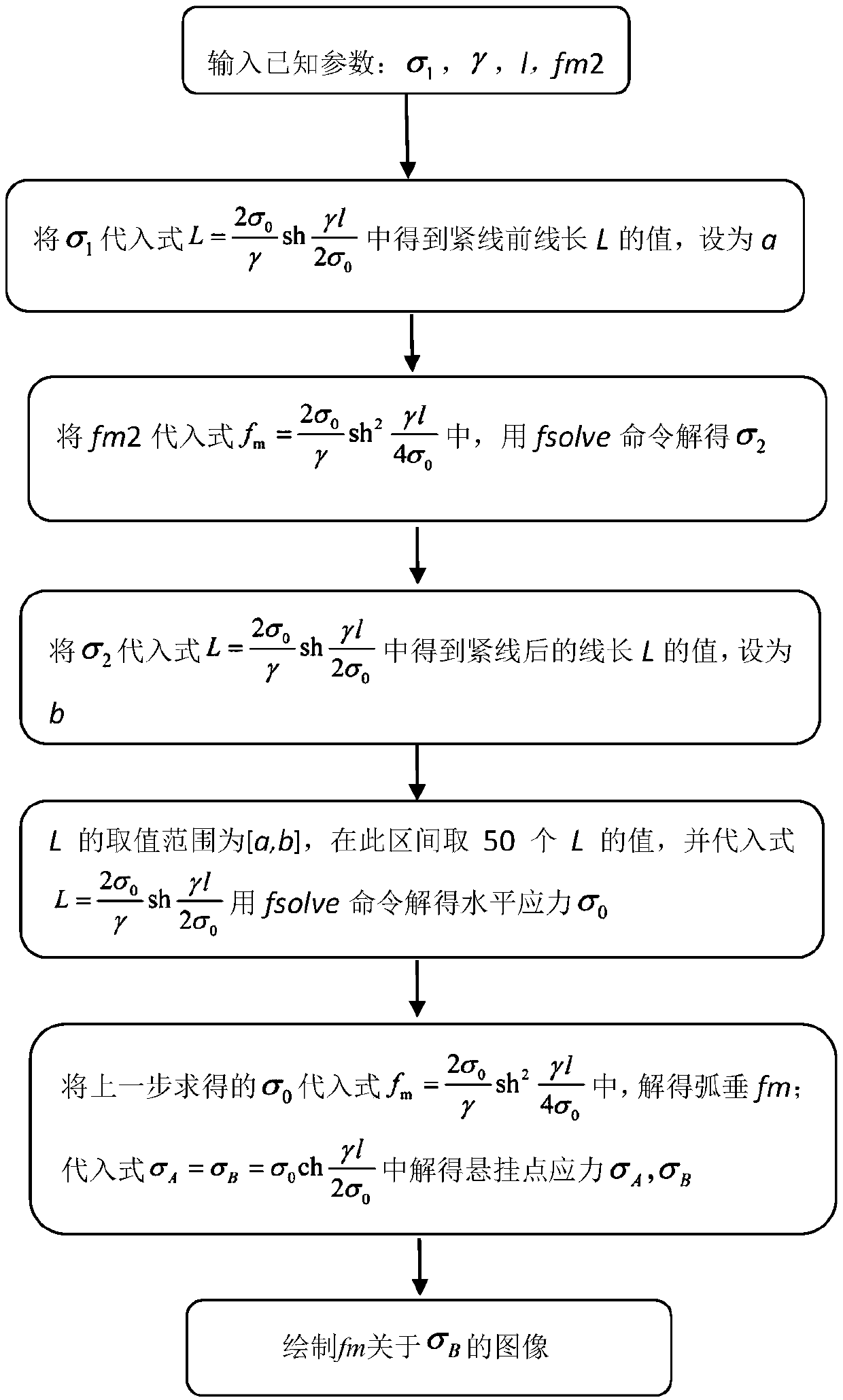

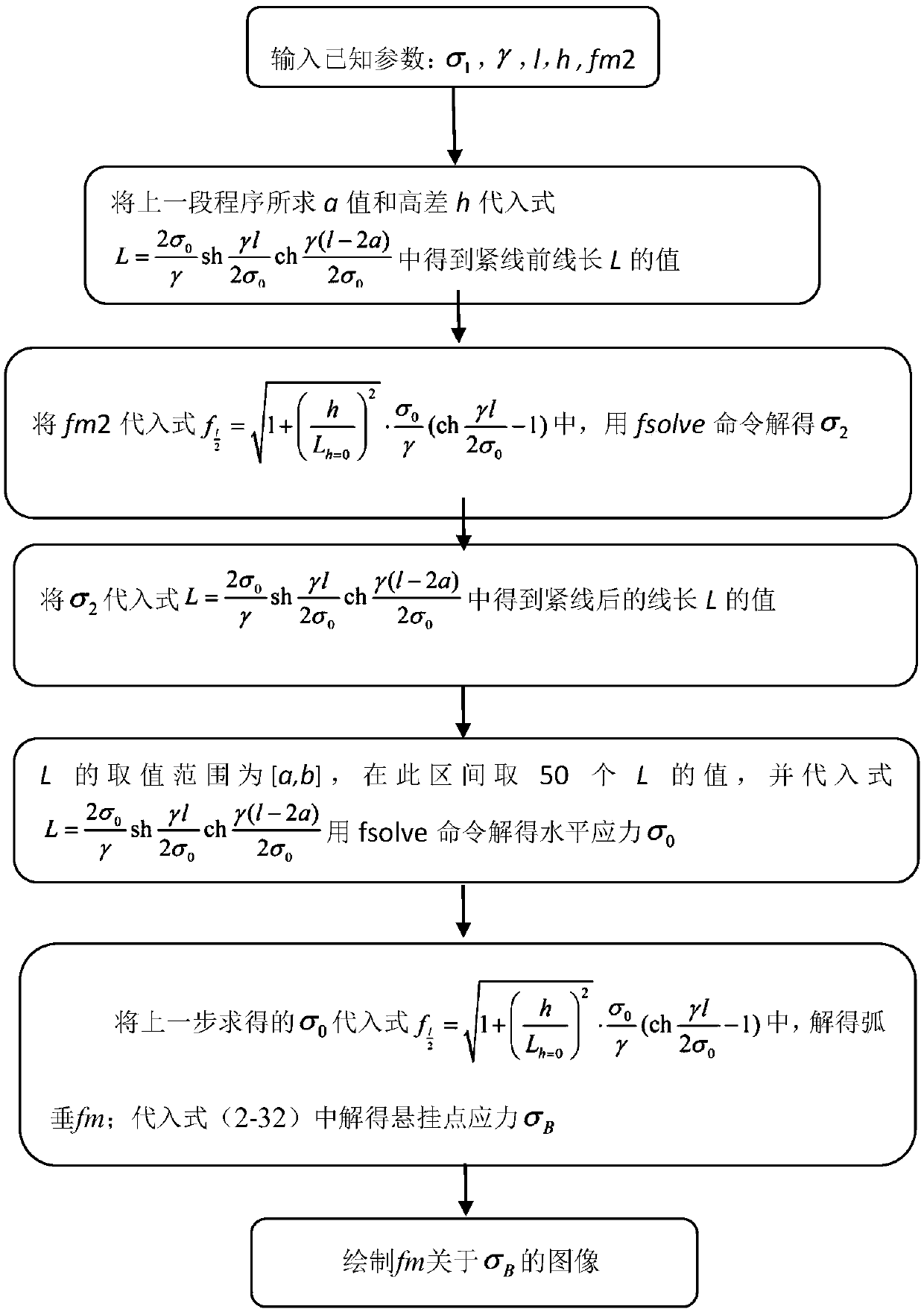

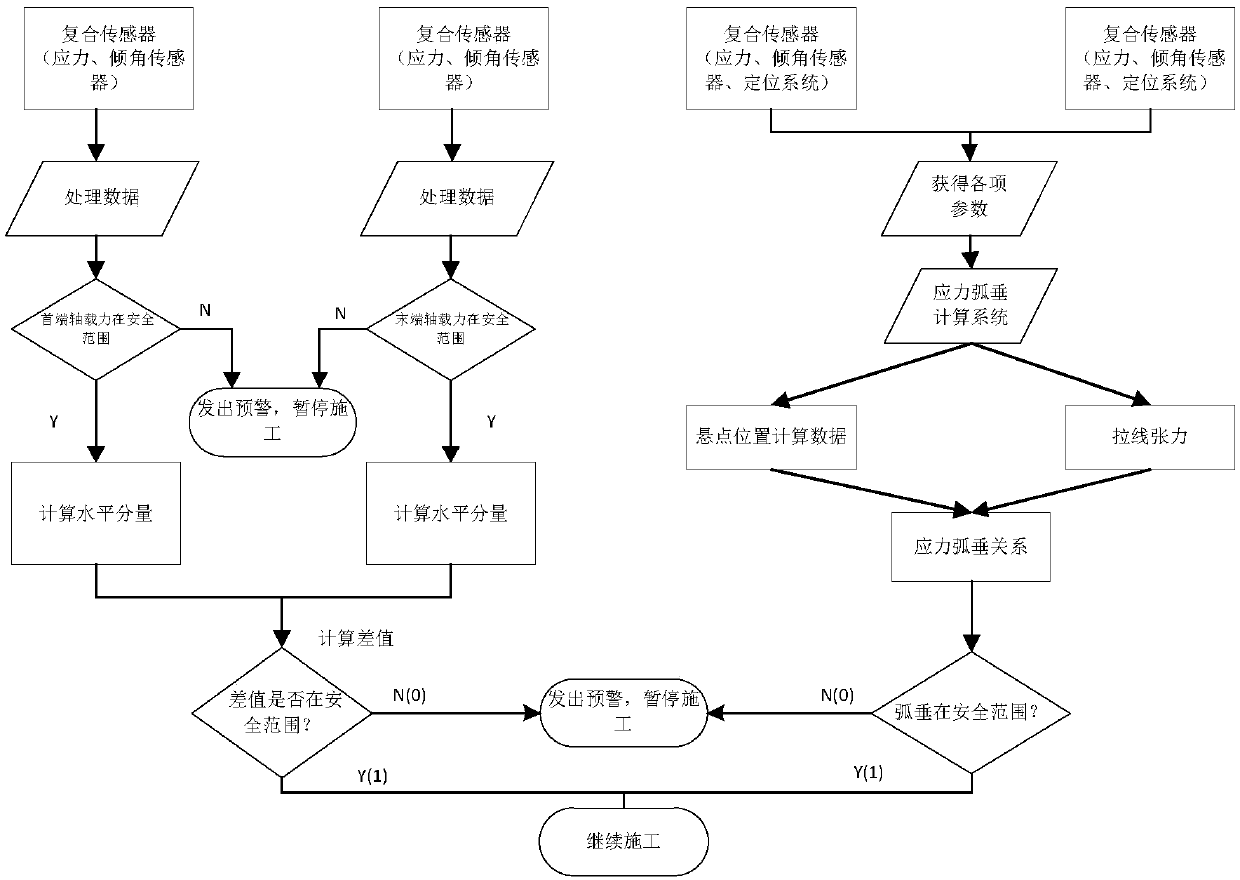

[0046] In the actual wiring process of the transmission line, one end of the overhead line is fixed on the tension tower at one end through a string of tension insulators, and the pulleys are temporarily used to support the overhead line on the towers in the middle, and the wire is tightened on the tighter tower at the other end. , observe the sag at the same time, adjust to the design value; then mark; finally move the wires from the pulleys into the clamp. There is also a construction method that sets out the wire at the head end and tightens the wire at the end. The stay wires at the first and last ends bear direct axial stress. If the stress value exceeds the loadable value, the wire will be broken and an accident will occur. Therefore, it is necessary to install a group of composite sensors at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com