Experimental method for testing the performance evolution of cement-based materials for slab ballastless track structures

A technology of cement-based materials and ballastless track, which is applied in the direction of material inspection, testing material strength by applying repeated force/pulsation force, and analyzing materials. It can solve the problem of filling layer damage, track geometry and dynamic impact between wheel and rail , endangering the safety of life and property, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

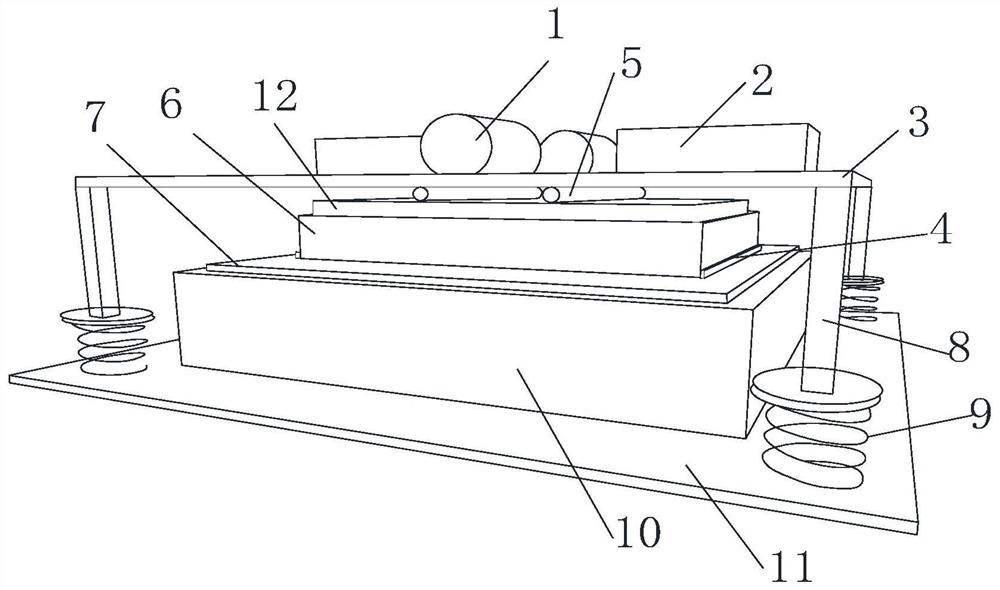

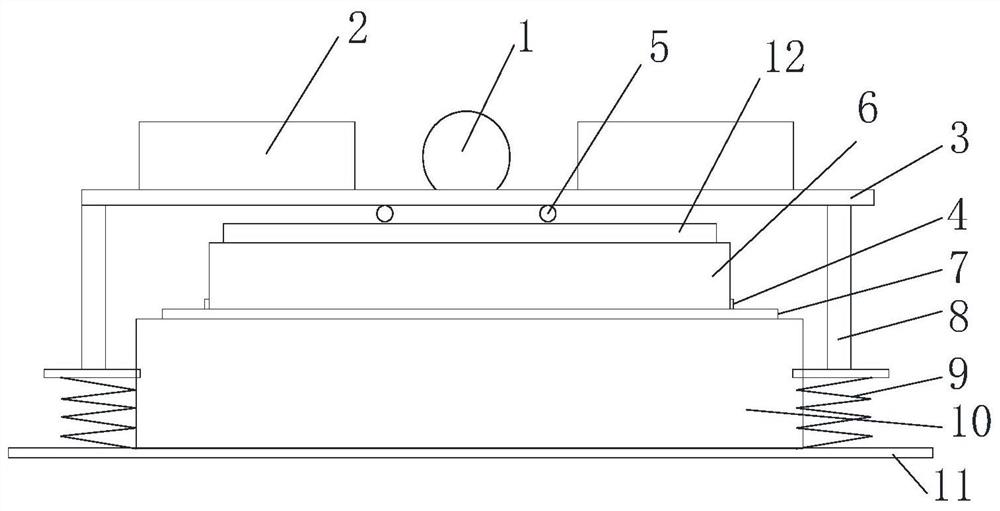

[0034] see figure 2 and image 3 , above the vibrating platform 3 are arranged two variable frequency vibrating motors 1 with a frequency of 12 to 50 Hz and an amplitude of 2 to 3 mm, and several 50 kg loading blocks 2. The vibrating platform 3 is connected to several The spring 9 is fixed on the base 11 on the ground.

[0035] see figure 2 and image 3 , the bottom surface of the vibration platform 3 is fixedly arranged with two smooth loading shafts 5 with a diameter of 20 mm, and the upper frequency conversion vibration motor 2 drives the vibration platform 3 and the two smooth loading shafts 5 to vibrate and apply impact loads to the test piece (Component) 12 simulates the process of high-speed train dynamic loads applying impact loads to slab ballastless track slabs through steel rails. And regardless of whether there is a load in the loading block 2, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com