Composite silicon-based waveguide structure and preparation method thereof

A waveguide structure and silicon-based technology, applied in the field of optical waveguides, can solve problems such as waveguide transmission loss, achieve the effects of reducing refractive index difference, high optical nonlinear threshold, and reducing waveguide transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

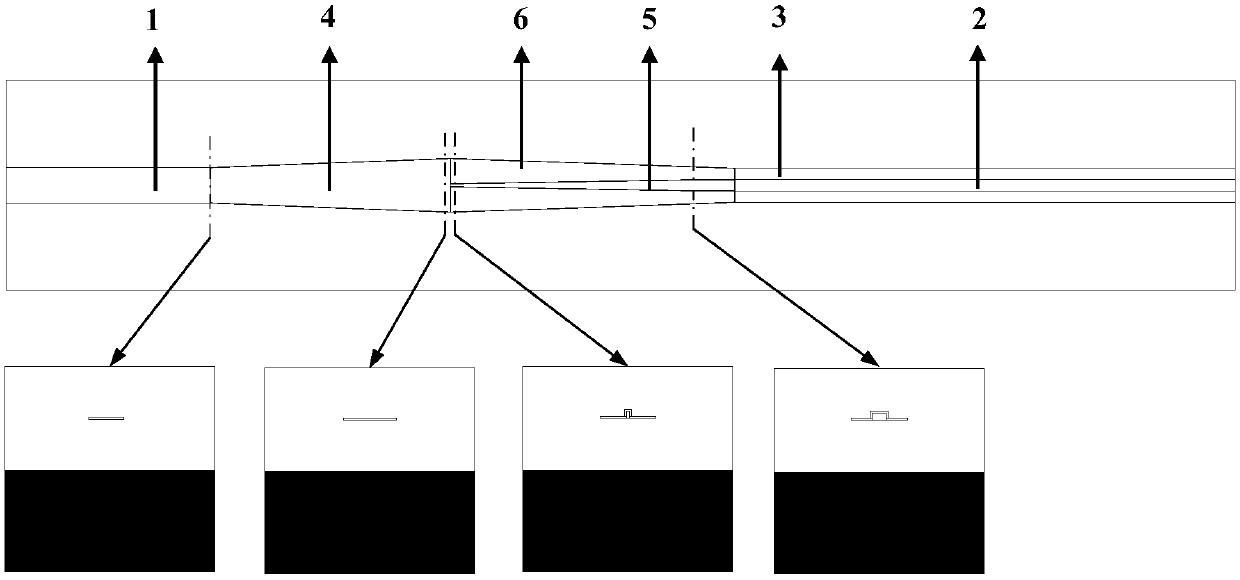

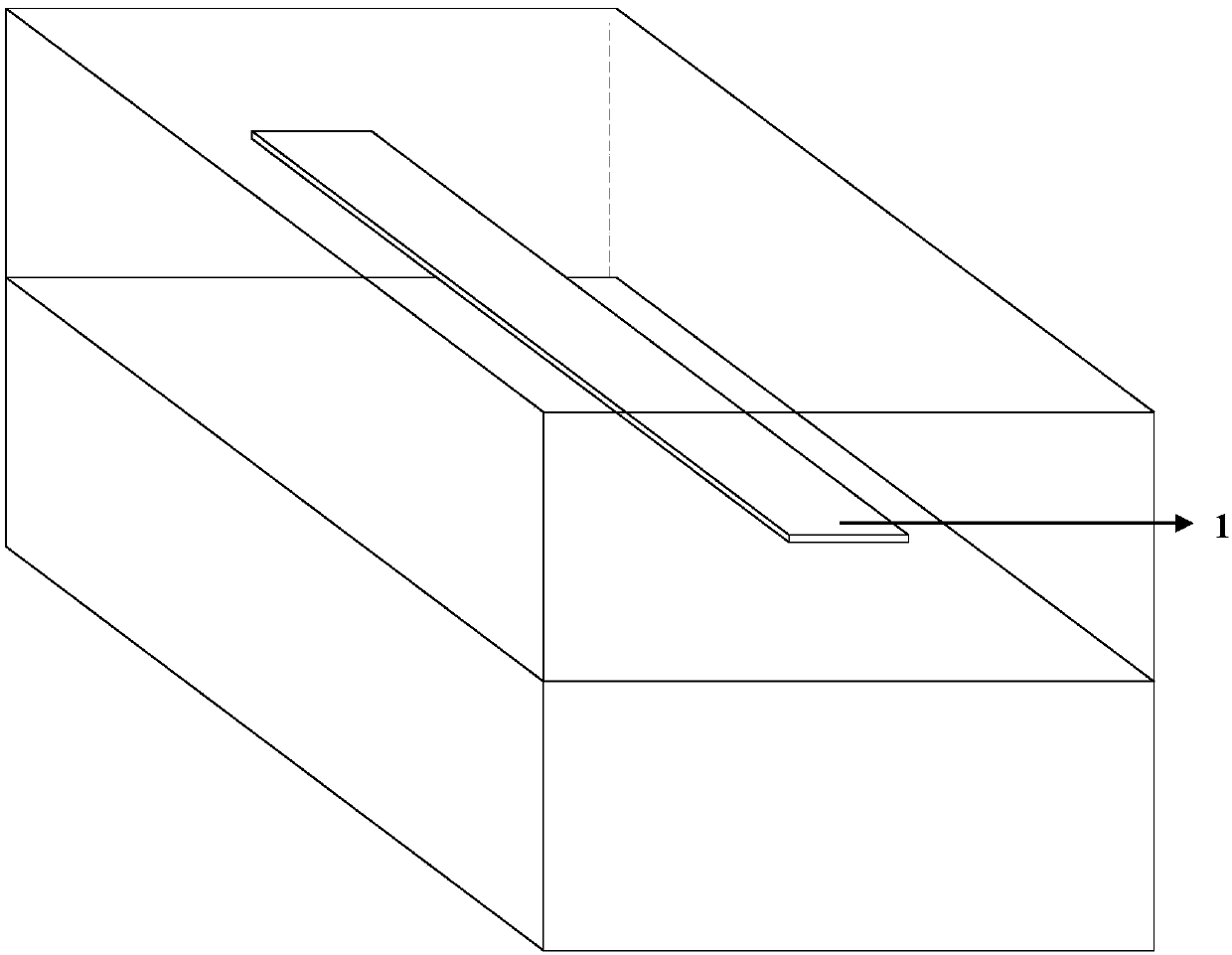

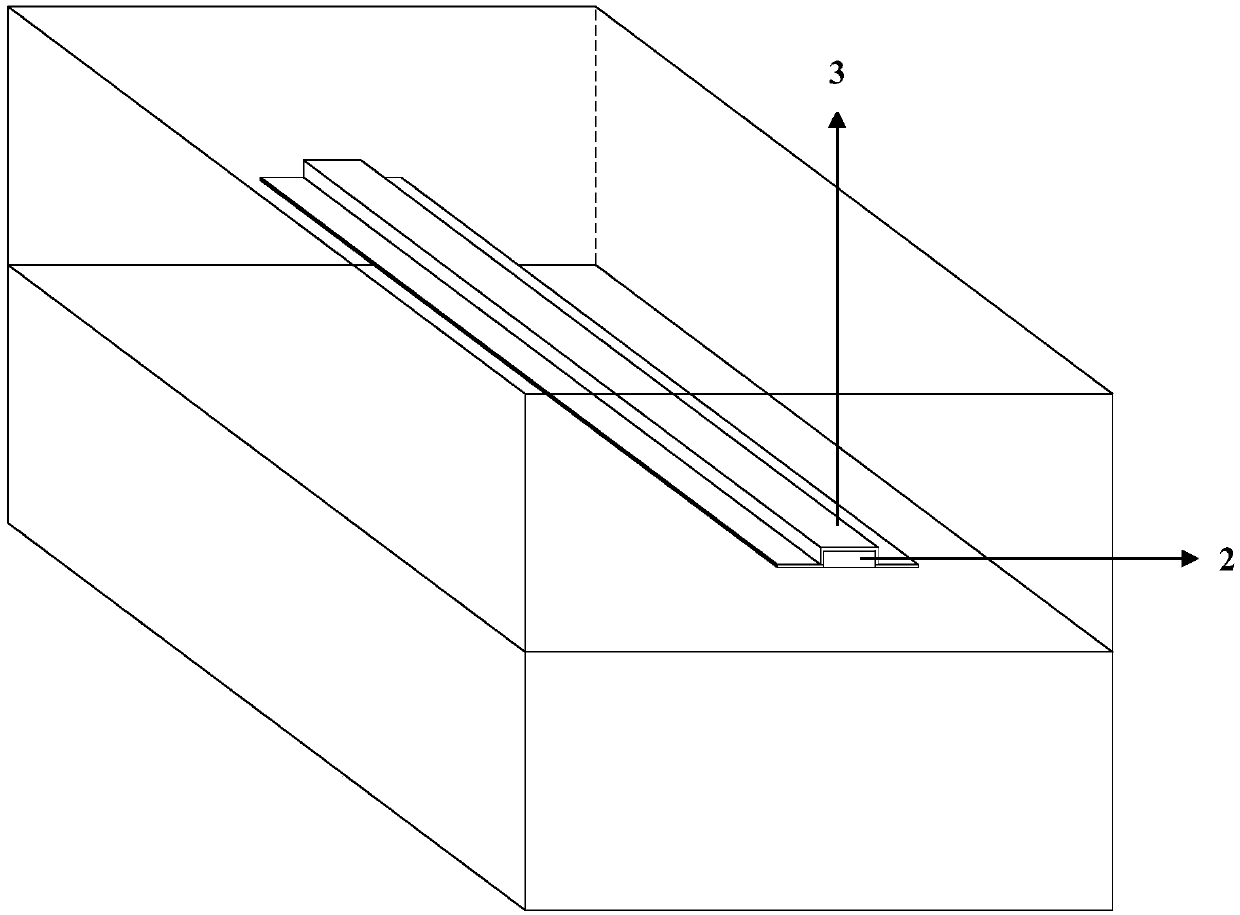

[0037] figure 1 It shows a composite silicon-based waveguide structure provided by the present invention, including: a weakly bound waveguide, such as figure 2 As shown, the first core layer 1 is included, and the first core layer 1 matches the mode field diameter of the weakly bound waveguide; the strongly bound waveguide, such as image 3 As shown, the second core layer 2 and the third core layer 3 covering the top and sidewalls of the second core layer 2 are included; the spot conversion structure, such as Figure 4 As shown, it includes a weakly bound part and a strong bound part connected to the weakly bound waveguide and the strongly bound waveguide respectively; the weakly bound part and the strong bound part are respectively connected to the weakly bound waveguide and the The strong confinement waveguide conforms to the waveguide structure. Through layered patterning, two waveguide structures can be formed on the chip, a weakly bound waveguide and a strongly bound w...

Embodiment 2

[0043] A preparation method of a composite silicon-based waveguide structure, the film of the second core layer 2 is placed on the substrate layer and the lower cladding layer, and the pattern photolithography is carried out, and the second core layer 2 is dry etched; on the second core layer 2, using a chemical vapor deposition method to make a thin film of the first core layer 1; performing pattern photolithography on the thin film of the first core layer 1, and dry etching the first core layer 1; on the first core layer 1 The upper cladding layer is fabricated by chemical vapor deposition. The pattern photolithography is ultraviolet gray scale photolithography.

[0044] It should be pointed out that if it is necessary to fabricate the gradient structure, it also includes using photolithography to fabricate the gradient structure before patterning the thin film of the second core layer 2 .

[0045] It should be pointed out that the pattern lithography can also be electron b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com