A crystallization auxiliary film for maldi target plate

A crystallization-assisted and target-plate technology, which is applied in the parts of discharge tubes, particle separation tubes, and particle separator tubes, etc., can solve the problems of unsatisfactory dissociation effect, affecting the quality of the spectrum, and poor experimental repeatability, and achieves a high level of improvement. The effect of experiment repetition rate, improving detection efficiency and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

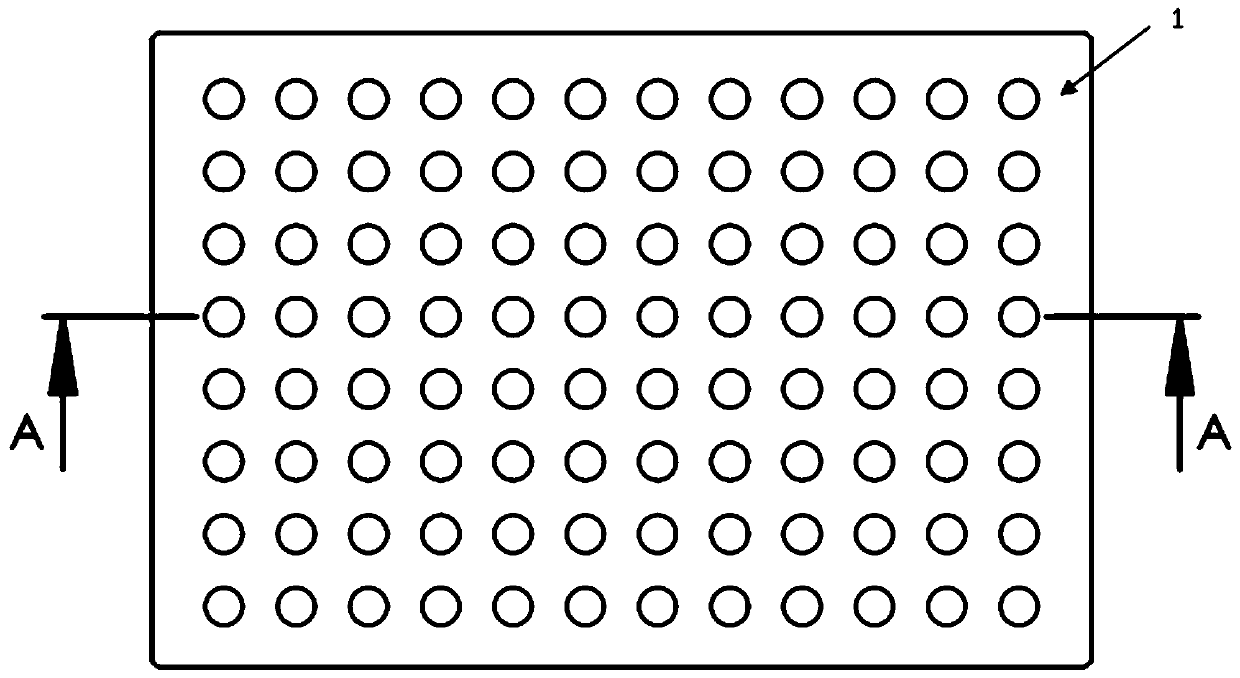

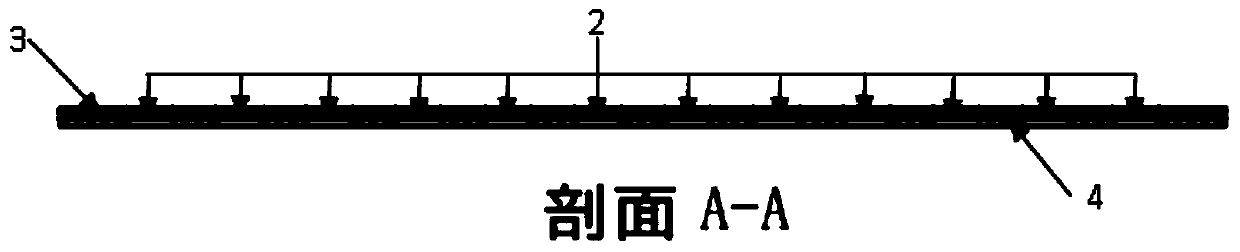

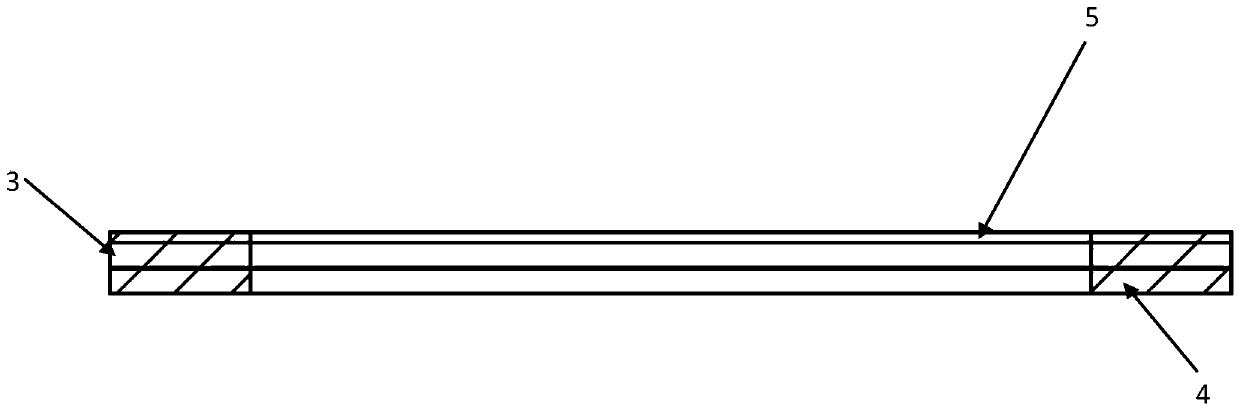

[0037] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , including a crystallization auxiliary membrane membrane body 1 , side wall holes 2 , colloid layer 3 , and a release membrane 4 . There should also be a layer of protective film 5 on the surface of the colloid layer 3 to play the role of protecting the colloid. In this embodiment, the crystallization assisting film 1 is placed on the surface of the target plate 6 with the target point, and is closely attached to the target plate 6 under the action of the colloid layer 3, and the crystallization assisting film 1 is provided with side wall holes 2 Through to the target point 7 on the surface of the target plate 6, the side wall hole 2 on the auxiliary film and the target point 7 on the target plate ensure that the axis deviation is 0-5 mm.

[0038] In this embodiment, preferably, the colloidal layer of the crystallization auxiliary membrane is made of viscous materials such as rubber and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com