Full-automatic shrimp washing and boiling equipment

A fully automatic, equipment-based technology, applied in shrimp/lobster processing, crustacean processing, slaughtering, etc., can solve problems such as death, lead poisoning, and time-consuming crayfish, and achieve the effect of high control precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

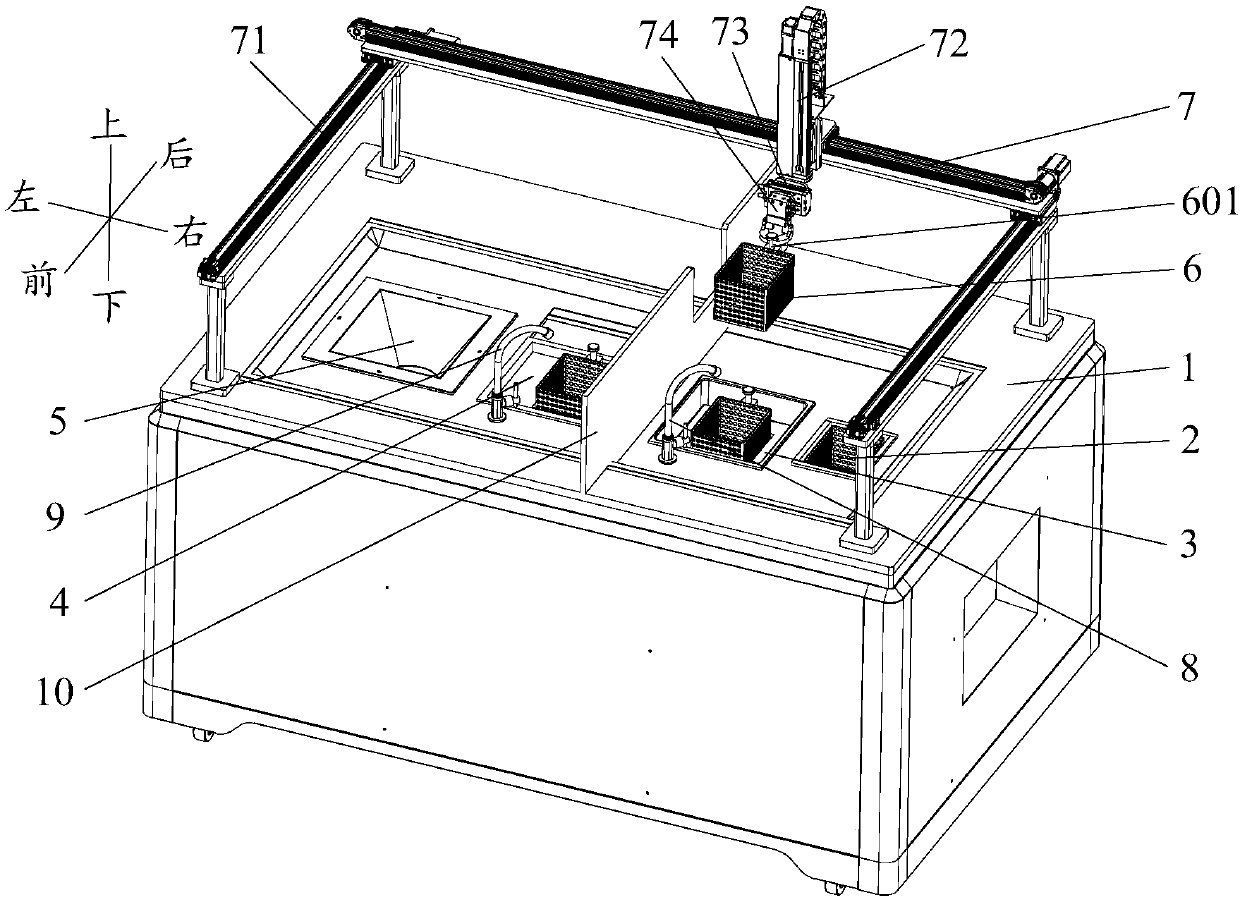

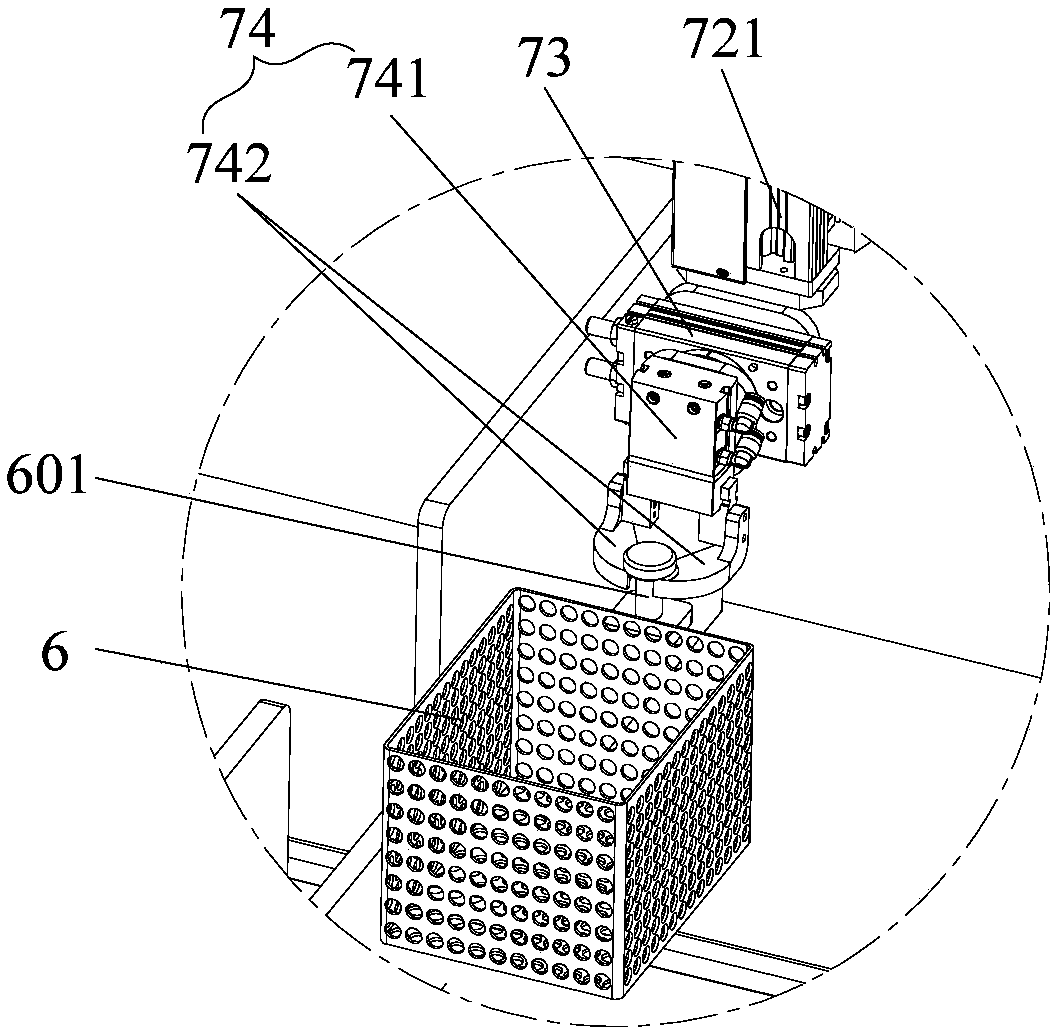

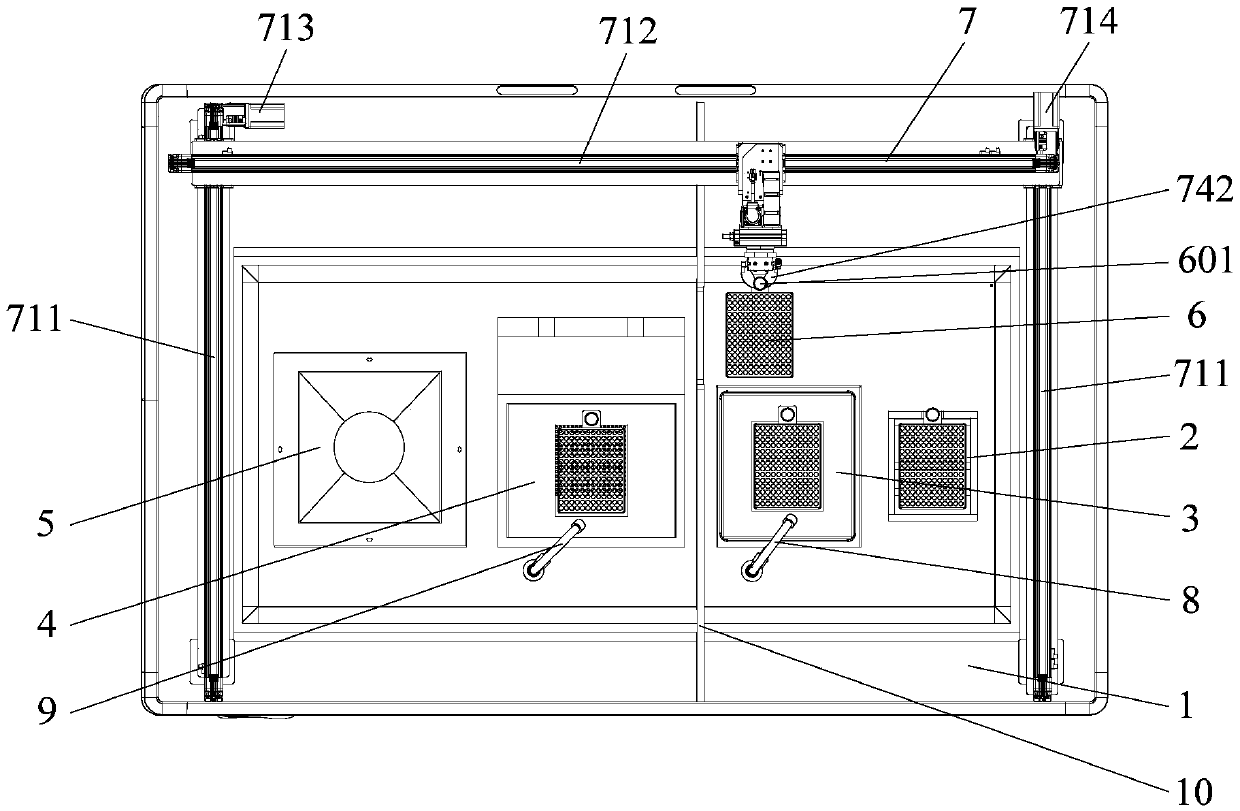

[0057] like figure 1 and image 3 As shown, the transfer mechanism 7 includes a translation mechanism 71, a lifting mechanism 72, a rotation mechanism 73 and a clamp device 74; the translation mechanism 71 is installed on the frame 1, and can move relative to the frame 1; the lifting mechanism 72 is installed on the translation mechanism 71, And can move relative to the translation mechanism 71; the rotation mechanism 73 is installed on the lifting mechanism 72, and can rotate relative to the lifting mechanism 72; The above-mentioned design can realize the clamping of the water filter basket 6, and the flexible translation, lifting and rotation of the shrimp along with the water filter basket 6, that is, the transfer mechanism 7 can clamp the water filter basket 6, and drive the water filter basket 6 to translate, Lifting and rotating, so as to realize automatic shrimp washing, cooking and loading operations, replacing manual operations, improving work efficiency and reducing...

Embodiment 2

[0063] The transfer mechanism 7 includes a transfer robot arm and a gripper device installed on the front end of the transfer robot arm. The gripper device is used to grip the filter basket 6 . The transfer robot arm controls the gripper device to translate, lift and rotate. The water filter basket 6 is clamped by the clamp device, and the translation, lifting and rotation of the water filter basket 6 is realized by using the transfer mechanical arm, with flexible operation and high control precision. Specifically, under the condition that the automatic control of ultrasonic cleaning and boiling remains unchanged, a 6-axis or 4-axis mechanical arm can be used to transport the shrimp, and the whole process can also be realized.

Embodiment 3

[0065] The difference from Embodiment 1 is that there is no need to use the transfer mechanism 7 to drive the water filter basket 6 to turn over. For example, a baffle plate that can be automatically opened can be set on the water filter basket 6, and the water in the water filter basket 6 can be poured out by automatically opening the baffle plate. Shrimp, for this solution, the rotation mechanism 73 on the transfer mechanism 7 can be canceled, and the clamp device can be directly installed on the lifting mechanism, and other structures remain unchanged, so that the transfer mechanism 7 can be used to clamp the water filter basket 6 , driving the water filter basket 6 to translate and driving the automatic operation of the water filter basket 6 to lift.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com