Laser beam polishing method of fused quartz optical glass

An optical glass and laser polishing technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of residual stress limiting the practical application of laser polishing fused silica optical glass technology, residual thermal stress, etc., and achieve the elimination of residual heat stress, overcome uneven heat accumulation, and solve the effect of expensive and inefficient polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

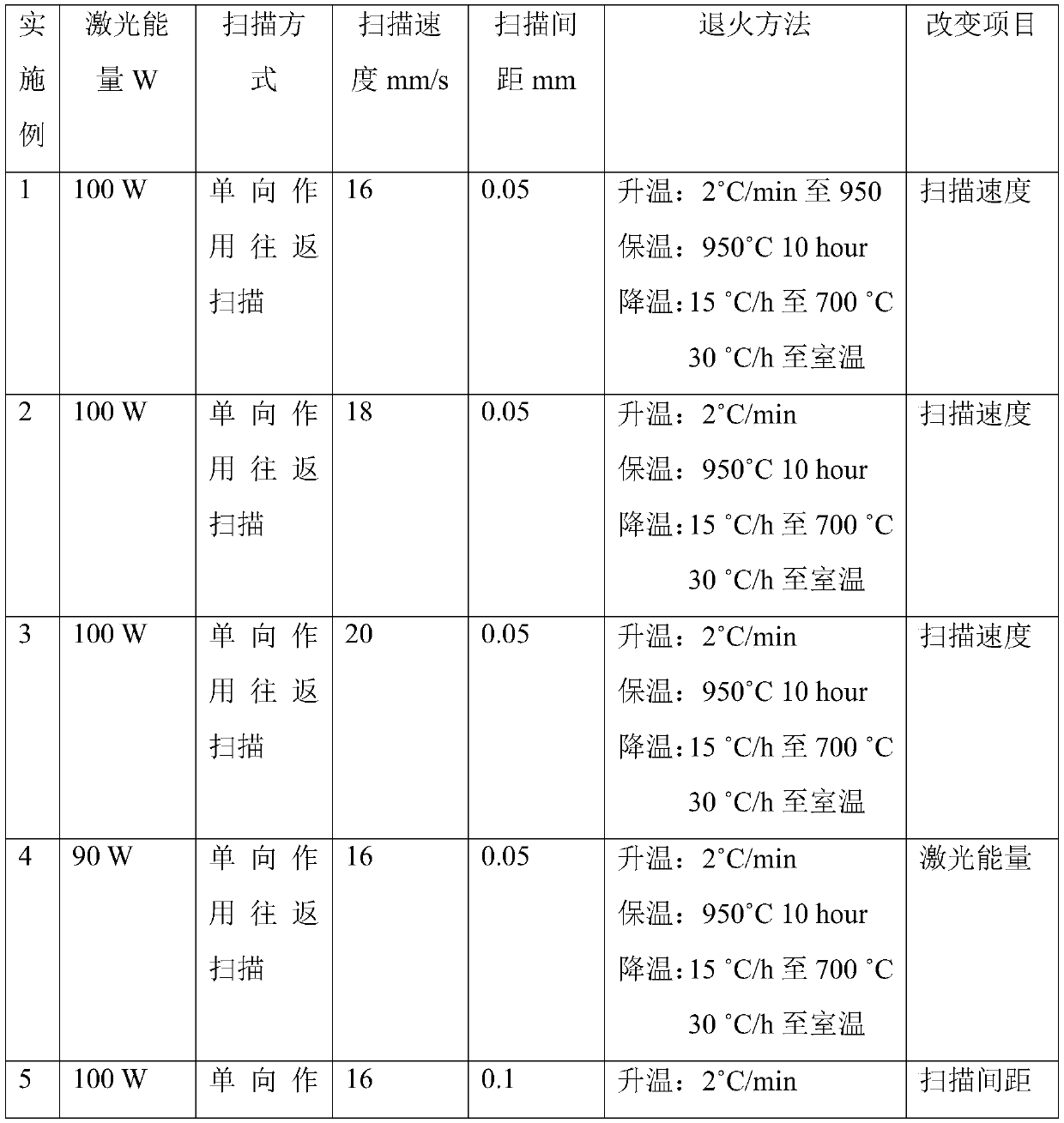

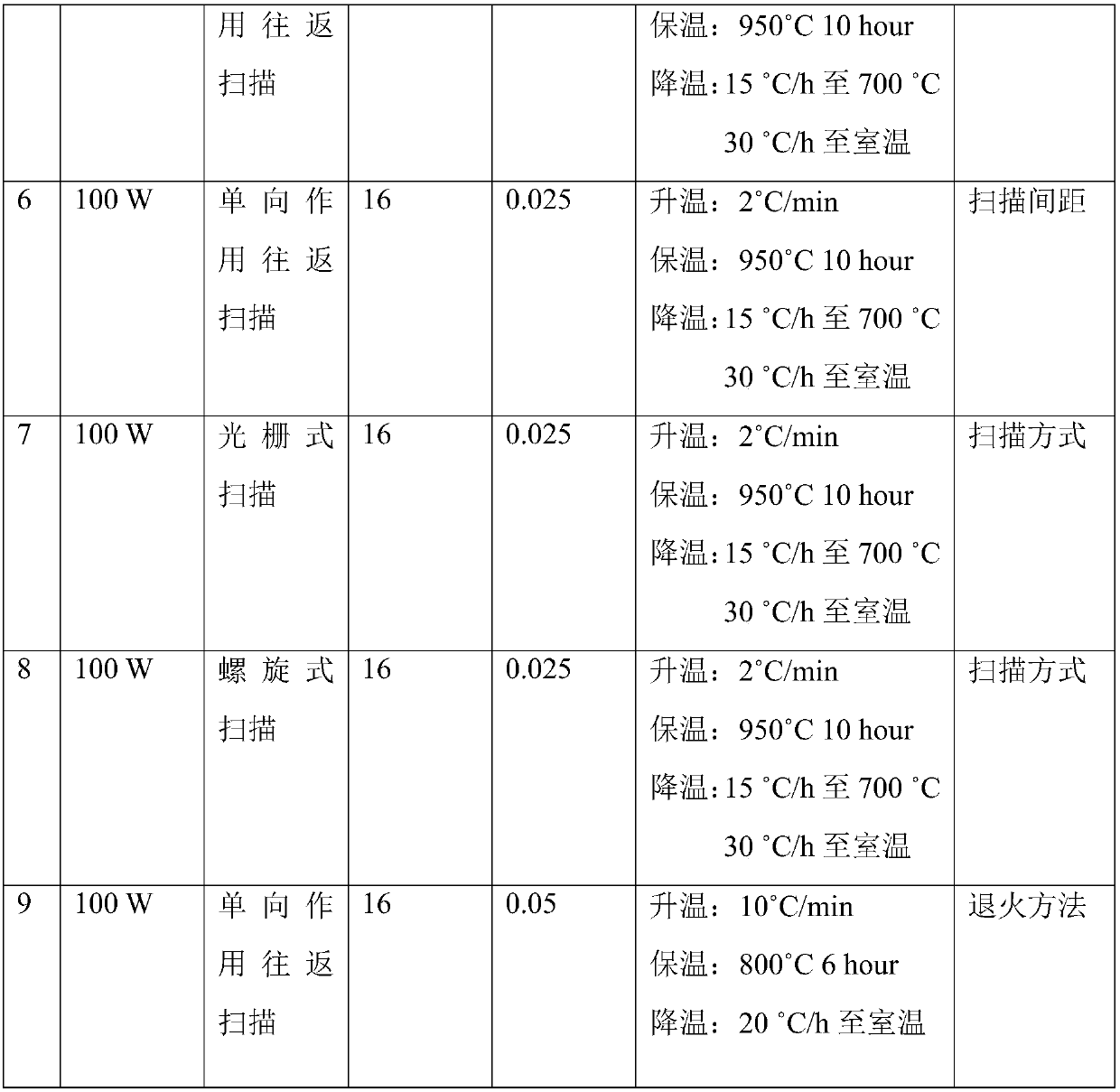

Examples

Embodiment 1

[0016] A laser beam polishing method for fused silica optical glass, comprising the following steps:

[0017] 1) Preparation of fused silica optical glass components before polishing: Polish the fused silica optical glass components with traditional polishing methods, then clean the fused silica optical glass with the optical component cleaning method to ensure that the surface of the components is clean and free of impurities, and then clean the fused silica optical glass Glass components are placed on a clean polished platform. The diameter of fused silica optical glass is 30mm, the thickness is 3mm, and the surface roughness before laser beam polishing is 0.229nm (using atomic force microscope, the detection area size is 1×1μm 2 ), the maximum stress before polishing is 4nm / cm;

[0018] 2) Polishing parameter setting and path planning: In the polishing control software, continuous CO 2 Laser light source. Polished fused silica glass can choose a one-way round-trip scanni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com