Ultrahigh-performance concrete, ultrahigh-performance concrete cored slab and preparation method thereof

An ultra-high-performance concrete technology, applied in floors, building components, buildings, etc., can solve problems such as free flow, poor fluidity, and easy air-dried crust on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a preparation method for the ultra-high performance concrete hollow slab described in the above technical solution, comprising the following steps:

[0049] Assembling the outer formwork to obtain the outer formwork cavity;

[0050] Fix the foam board in the outer formwork cavity, and form a pouring gap between the outer formwork and the foam board;

[0051] After pouring the ultra-high-performance concrete into the gap between the outer formwork and the foam board, spray a steam reducing agent on the pouring surface, and perform surface closing treatment to obtain a hollow blank;

[0052] After the hollow preform is steam-cured, the outer mold is removed to obtain an ultra-high performance concrete hollow slab.

[0053] The invention assembles the outer formwork to obtain the outer formwork cavity.

[0054] In the present invention, the outer formwork is preferably a steel formwork. The present invention has no special requirement...

Embodiment 1

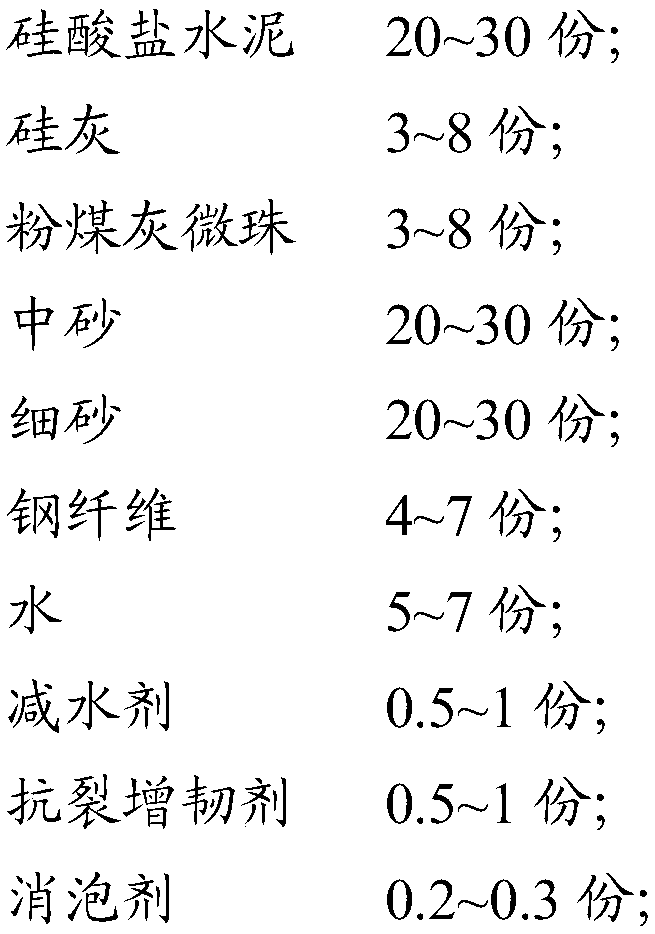

[0066] Ultra-high performance concrete contains the following components by weight: Portland 42.5R cement is 25 parts; silica fume is 5 parts; fly ash microbeads is 5 parts; medium sand is 22 parts; fine sand is 25 parts; 5 parts for steel fiber; 6 parts for water; 0.7 parts for water reducing agent; 0.8 parts for anti-crack toughening agent; 0.25 parts for defoaming agent; 40%.

Embodiment 2

[0068] Ultra-high performance concrete contains the following components and weight ratios: Portland 42.5R cement is 22 parts; silica fume is 6 parts; fly ash microbeads is 7 parts; medium sand is 22 parts; fine sand is 25 parts; 5 parts for steel fiber; 6 parts for water; 0.7 parts for water reducing agent; 0.8 parts for anti-crack toughening agent; 0.25 parts for defoaming agent; 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Splitting tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com