Primary refining integrated processing method for machine-picked curled green tea

A processing method and curly-shaped technology, which is applied in the field of integrated processing of primary refining of machine-picked curly-shaped green tea, can solve problems such as unstable quality and uneven dry tea, and achieve the goal of reducing picking costs, uniform dry tea, and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with specific embodiments.

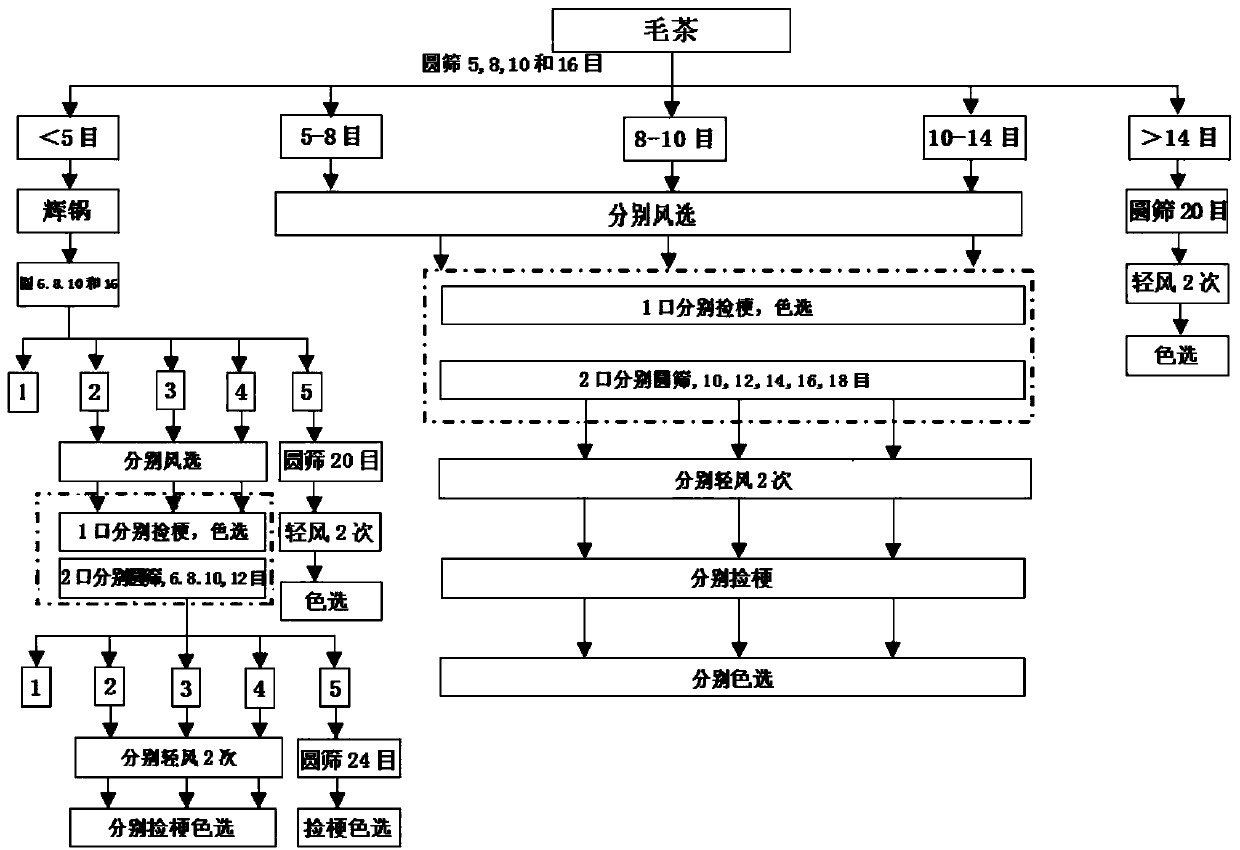

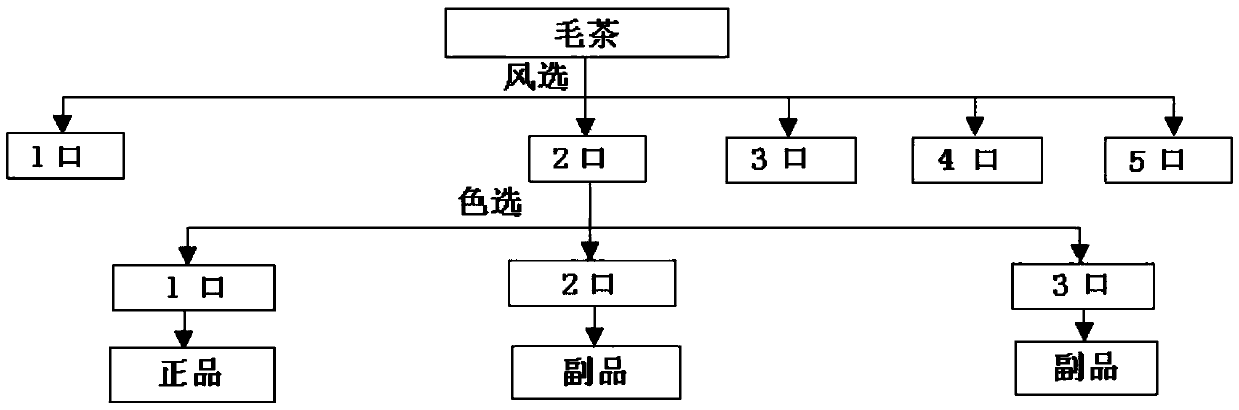

[0014] An integrated processing method for primary refining of machine-harvested curly-shaped green tea. Firstly, machine-harvested fresh leaves with one bud and two or three leaves as the raw material are used as raw materials, and then go through the processes of killing greens, kneading, rolling and frying for shaping, winnowing and color sorting. Finally, the new product of machine-picked curl-shaped green tea is finally obtained. Specifically include the following steps:

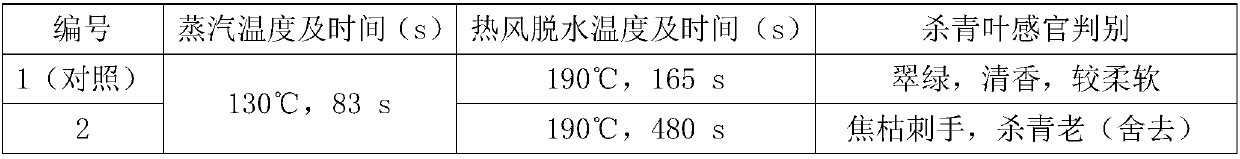

[0015] Step 1, using machine-harvested fresh leaves mainly with one bud and two and three leaves as raw materials, with a moisture content of 73% to 77%, and steam-heating to fix the green leaves so that the moisture content of the finished leaves is 58% to 64%.

[0016] Step 2: After the green leaves are cooled and regained moisture, a 6CR-Z65 rolling machine is used to knead according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com