Tea leaf producing and processing system and complex tea making method

A processing system and tea technology, applied in the direction of pre-extraction tea treatment, climate change adaptation, etc., can solve problems such as low drying efficiency, and achieve the effect of excellent effect, good stability and good processing consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

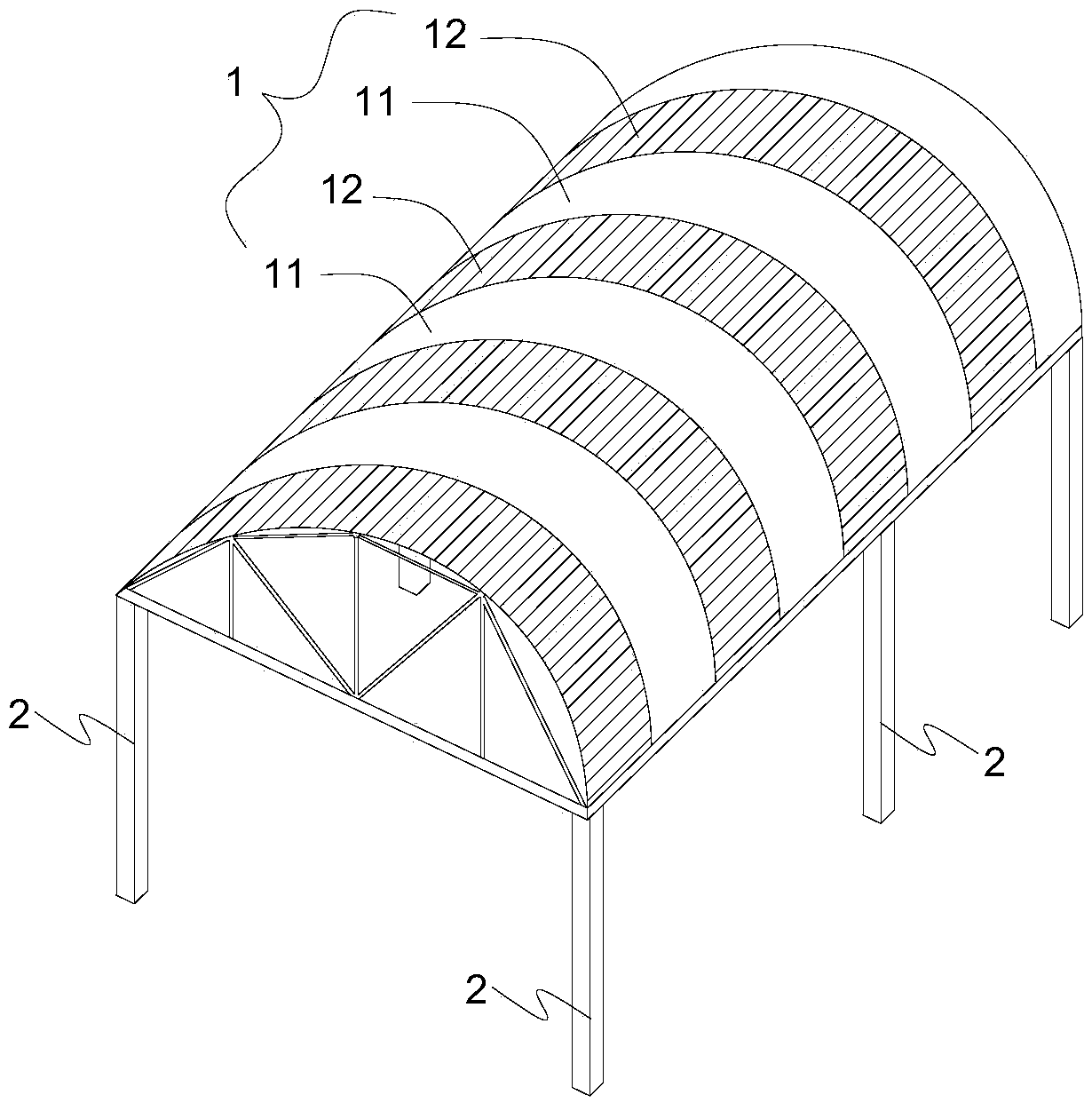

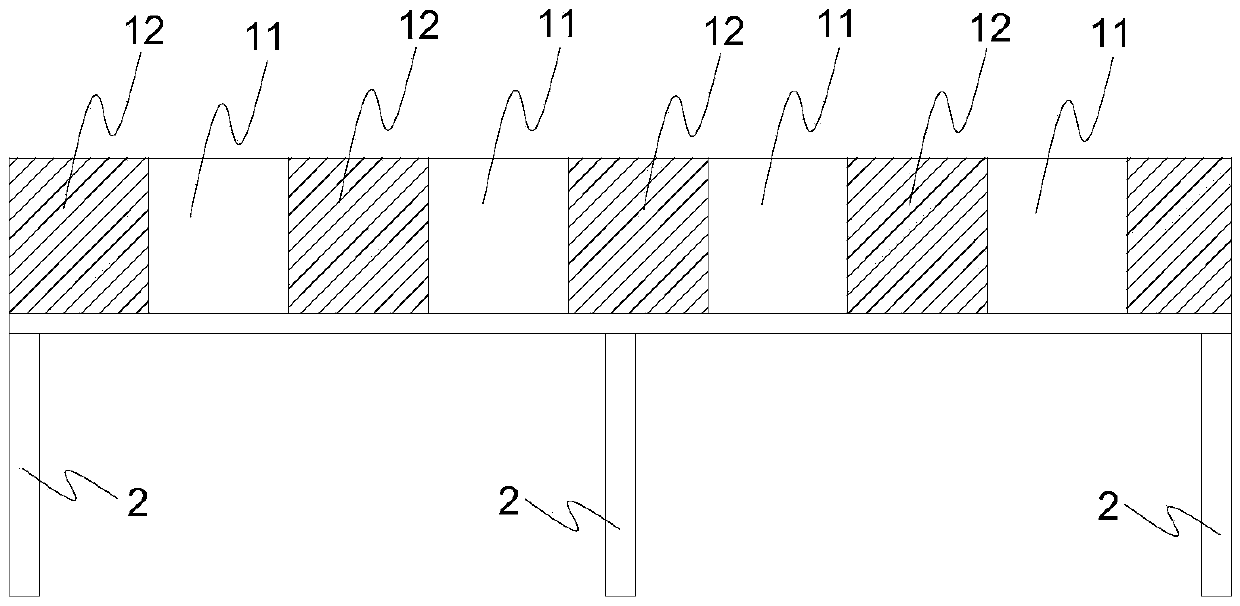

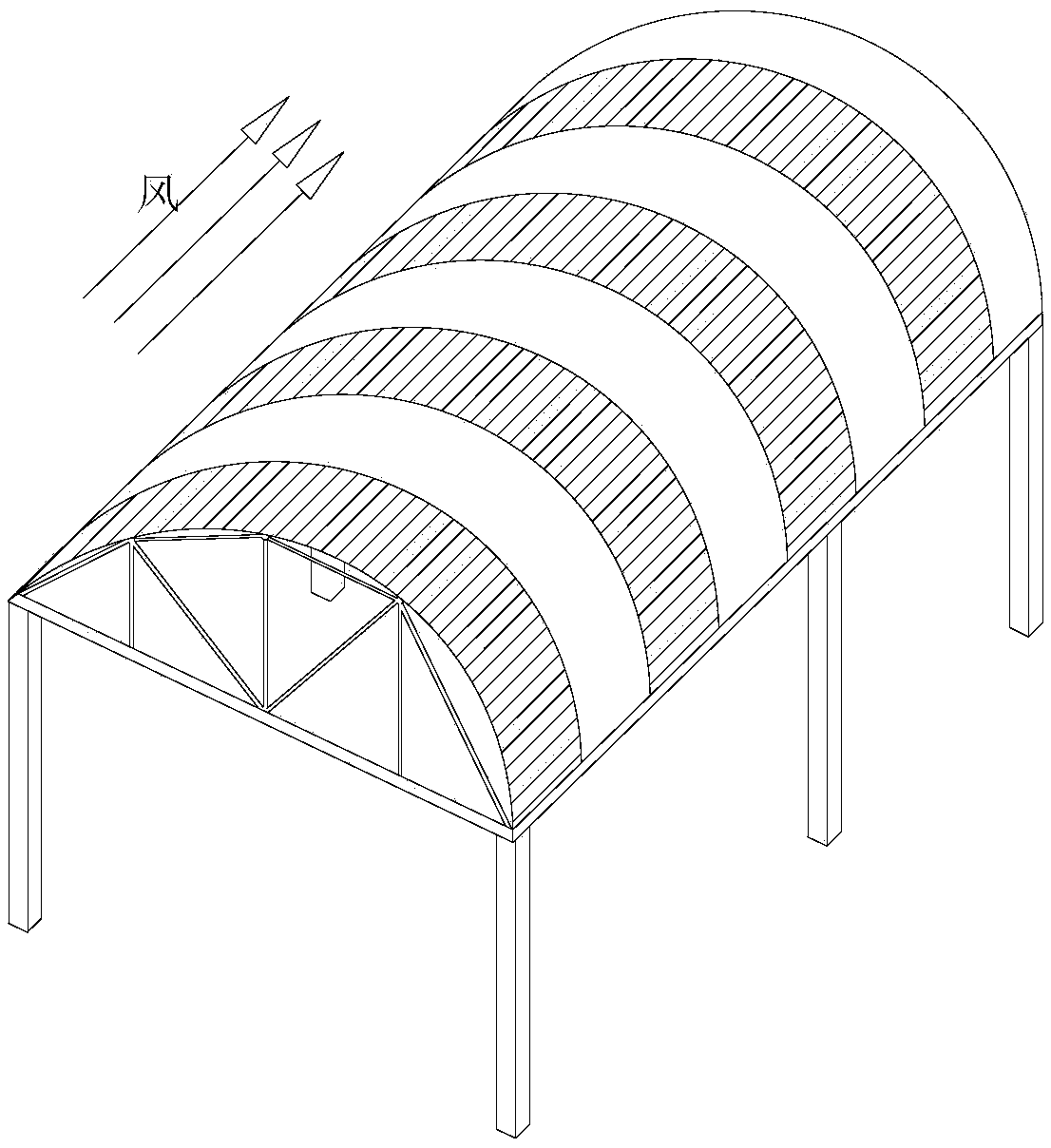

[0070] Such as Figure 1-5 The shown tea production and processing system includes a tea drying shed and a drying platform.

[0071] Its drying greenhouses such as Figure 1-3 As shown, the greenhouse has a plurality of pillars 2, and the pillars of the greenhouse realize the four-sided wall structure of the greenhouse. The pillars 2 are five meters high, and the ceiling 1 is in the shape of an arc-shaped protrusion (the height of the protrusion is 1.4m, and the width is 8.8m). The rain falls under the greenhouse Rapid sideways flow converging. There are drainage grooves on both sides of the roof of the greenhouse. After the rainwater gathers, it will flow along the drainage grooves, so as to prevent the ground water around the greenhouse from entering the interior of the greenhouse or forming ponds around the greenhouse to affect the humidity control of the greenhouse. Except for the main pillar 2 on all sides of the greenhouse, the overall openness is very high, such as ...

Embodiment 2

[0089] The same tea production and processing system as in Example 1 includes a tea drying stand and a drying shed. The inside of the drying shed is a flattened soil, and the tea drying stand is arranged in the drying shed. The state of the drying rack arrangement is as follows: Figure 5 As shown, the array is arranged, and the bluestone slabs with a thickness of 10cm are paved at the intervals of the drying stands. The wind kicked up the dust. The floor of the greenhouse is a mixed arrangement of mud and bluestone slabs. The mud has a good heat-absorbing and temperature-regulating effect. When the sun is sufficient in summer, the temperature in the greenhouse rises to a certain level, and the water in the mud evaporates. The temperature can be better controlled within a suitable range. In this way, the environment inside the greenhouse is very close to the state of drying tea in a shaded place such as the shade of a tree in the traditional tea making process, which can wel...

Embodiment 3

[0092] The same tea processing and production system as in Example 2 includes a greenhouse and a drying platform in the greenhouse. The main feature is that the greenhouse is located on a sunny half-hillside, and curtain walls or door panels that can be opened and closed are arranged between the pillars 2 of the greenhouse. After the sun goes down, the curtain wall or door panel can be closed to form a closed space inside the greenhouse, so as to prevent the quality of tea drying from being affected by condensation of water vapor at night in areas with low temperature at night.

[0093] Further, a sunshade net that can be opened or closed by electric control is also provided under the ceiling of the tea drying booth, and various indoor automatic sunshade net devices can be referred to for the specific structure. The collection roll of the sunshade net driven by the motor is unfolded or retracted to achieve further shading for the interior of the tea drying shed. For some areas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com