Tobacco sheet additive for low-temperature cigarette and application method of tobacco sheet additive

A tobacco sheet and low-temperature cigarette technology, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, can solve the problems of high alkalinity, enhanced irritation, inability to fully volatilize and atomize cigarettes, and achieve convenient operation and improved smoking satisfaction. High effect of feeling and strength, stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

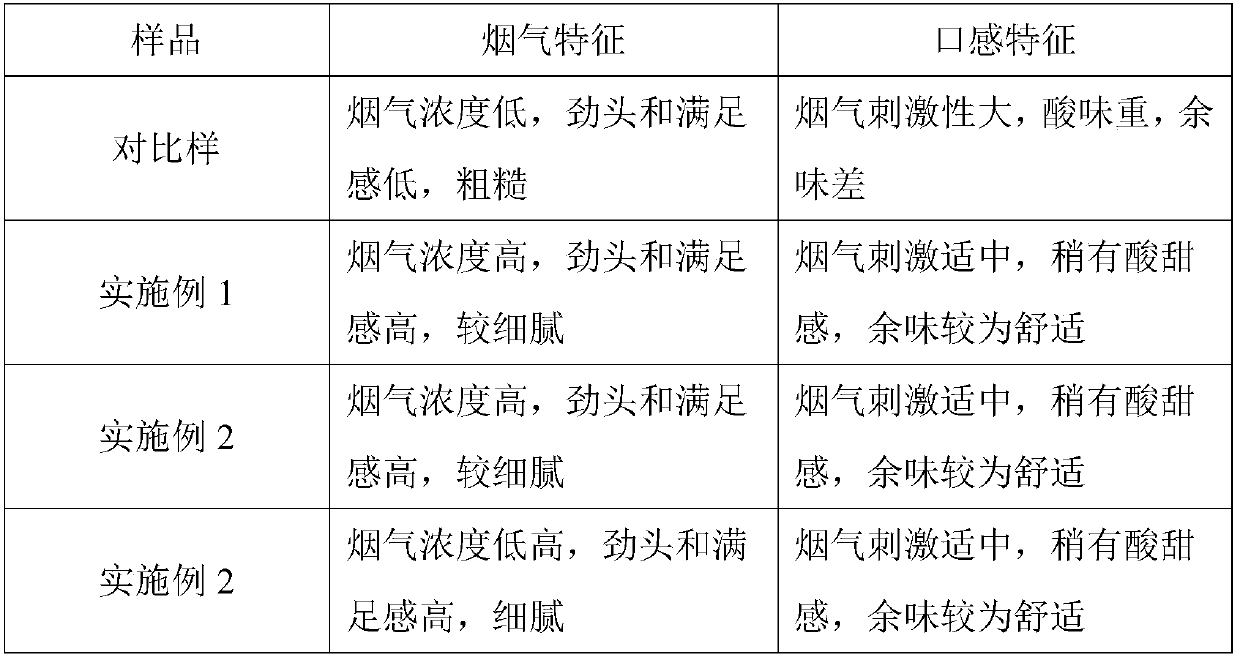

Examples

Embodiment 1

[0027] Embodiment 1: The use method of low-temperature cigarette tobacco sheet additive

[0028] S1. Soaking and extraction stage a: add water three times the mass of the tobacco raw material and additives accounting for 0.5% of the mass of the tobacco raw material to the weighed tobacco raw material, place it in an ultrasonic extraction machine for soaking at 50°C, and ultrasonic extraction for 2 hours, to obtain a solid-liquid mixture, the solid-liquid mixture is filtered and separated, and solid and extract are obtained after solid-liquid separation; the additive consists of 25% potassium bicarbonate, 43% sodium carbonate, 12% ammonium phosphate, 20% lemon Potassium acid.

[0029] S2. Soaking and extraction stage b: add water twice the mass of tobacco raw material to the solid in step S1, place it in an ultrasonic extraction machine for soaking at 50°C, and ultrasonically extract for 2 hours to obtain a solid-liquid mixture. The liquid mixture is separated by filtration to...

Embodiment 2

[0033] Embodiment 2: The use method of low-temperature cigarette tobacco sheet additive

[0034] S1. Soaking extraction stage a: add water 3.5 times the mass of the tobacco raw material and additives accounting for 0.6% of the mass of the tobacco raw material to the weighed tobacco raw material, place it in an ultrasonic extraction machine for soaking at 48°C, and ultrasonic extraction for 2.5 hours, to obtain a solid-liquid mixture, the solid-liquid mixture is filtered and separated, and the solid and the extract are obtained after the solid-liquid separation; the additive consists of 15% potassium bicarbonate, 50% sodium carbonate, 20% ammonium phosphate, and 15% lemon Potassium acid.

[0035] S2. Soaking and extraction stage b: Add 2.5 times the quality of tobacco raw material water to the solid in step S1, place it in an ultrasonic extraction machine for soaking at 48°C, and ultrasonically extract for 2.5 hours to obtain a solid-liquid mixture. The liquid mixture is separat...

Embodiment 3

[0039] Embodiment 3: The use method of low-temperature cigarette tobacco sheet additive

[0040] S1. Soaking and extraction stage a: add water 4 times the mass of the tobacco raw material and additives accounting for 0.8% of the mass of the tobacco raw material to the weighed tobacco raw material, place it in an ultrasonic extraction machine for soaking and ultrasonic extraction at 55°C After 3 hours, a solid-liquid mixture was obtained, and the solid-liquid mixture was filtered and separated to obtain a solid and an extract after solid-liquid separation; the additives consisted of 30% potassium bicarbonate, 40% sodium carbonate, 15% ammonium phosphate, and 15% potassium citrate.

[0041] S2. Soaking and extracting stage b: Add 3 times the quality of tobacco raw material water to the solid in step S1, place it in an ultrasonic extraction machine, soak it at 55°C, and extract it ultrasonically for 3 hours to obtain a solid-liquid mixture. The solid-liquid mixture is separated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com