Injection molding machine multistage mold locking molding method

An injection molding machine and multi-stage technology, which is applied in the field of multi-stage clamping molding of injection molding machines, can solve the problems of long production cycle, high injection equivalent, and poor molding quality of injection molding products, so as to improve molding quality, ensure volume, and increase injection equivalent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

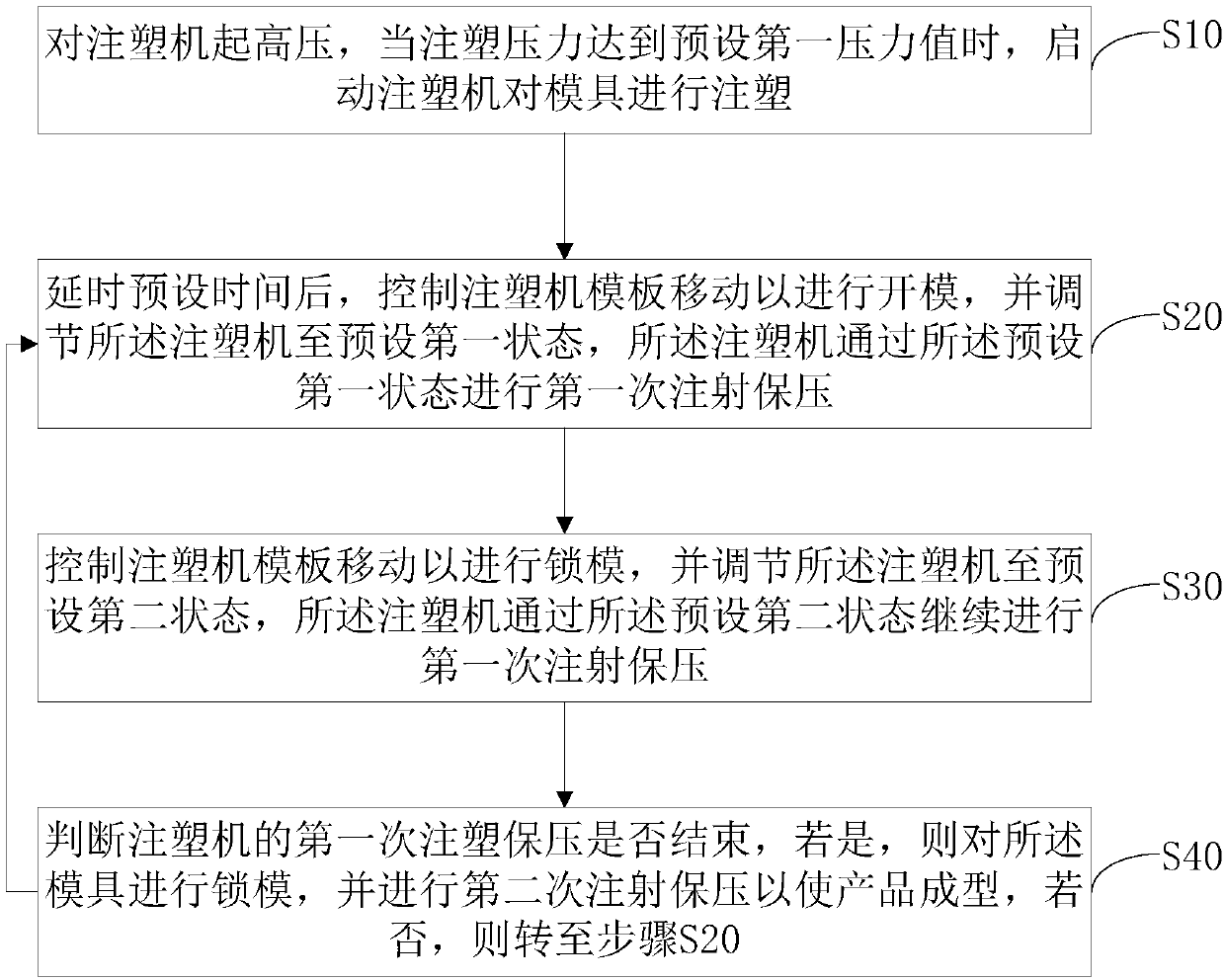

[0029] Such as figure 1 As shown, this embodiment provides a method for multi-stage clamping molding of an injection molding machine, including steps:

[0030] S10: Apply high pressure to the injection molding machine, and start the injection molding machine to inject the mold when the injection pressure reaches the preset first pressure value;

[0031] S20: After delaying the preset time, control the movement of the template of the injection molding machine to open the mold, and adjust the injection molding machine to the preset first state, and the injection molding machine performs the first injection protection through the preset first state. pressure;

[0032] S30: Control the movement of the template of the injection molding machine to perform mold clamping, and adjust the injection molding machine to a preset second state, and the injection molding machine continues to perform the first injection pressure maintaining through the preset second state;

[0033] S40: Dete...

Embodiment 2

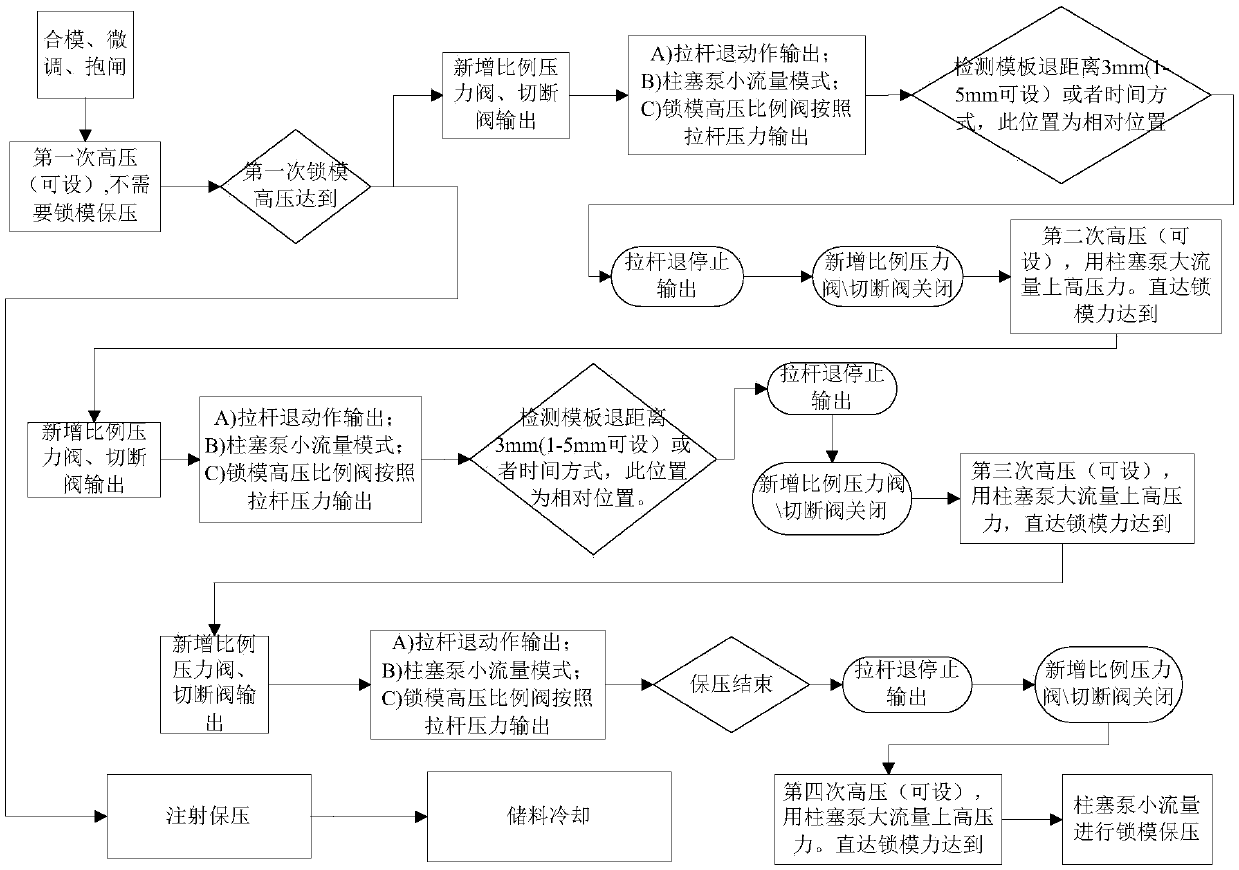

[0052] Such as figure 2 As shown, this embodiment provides a multi-stage mold-clamping molding method for an injection molding machine. The difference between this embodiment and Embodiment 1 is that a proportional pressure valve, a shut-off valve, and a high-pressure proportional valve for mold clamping are newly added.

[0053] The newly added proportional pressure valve, cut-off valve and high-pressure mold clamping proportional valve are set in the mold clamping hydraulic system of the injection molding machine to control the micro-opening and mold clamping process of the cooperative template.

[0054] When the injection molding machine closes the mold, locks the brake and reaches the high pressure of the mold clamping, the injection molding machine starts injection molding. After a certain delay, the injection molding machine template starts to slightly open, that is, the template moves relatively, and the mold is opened. At this time, the proportional pressure is added. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com