Integrated flocculent precipitating device

A sedimentation device and flocculation technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of large equipment footprint and difficult control of sediment discharge time, and achieve an The effect of small floor area, low mechanical energy consumption and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

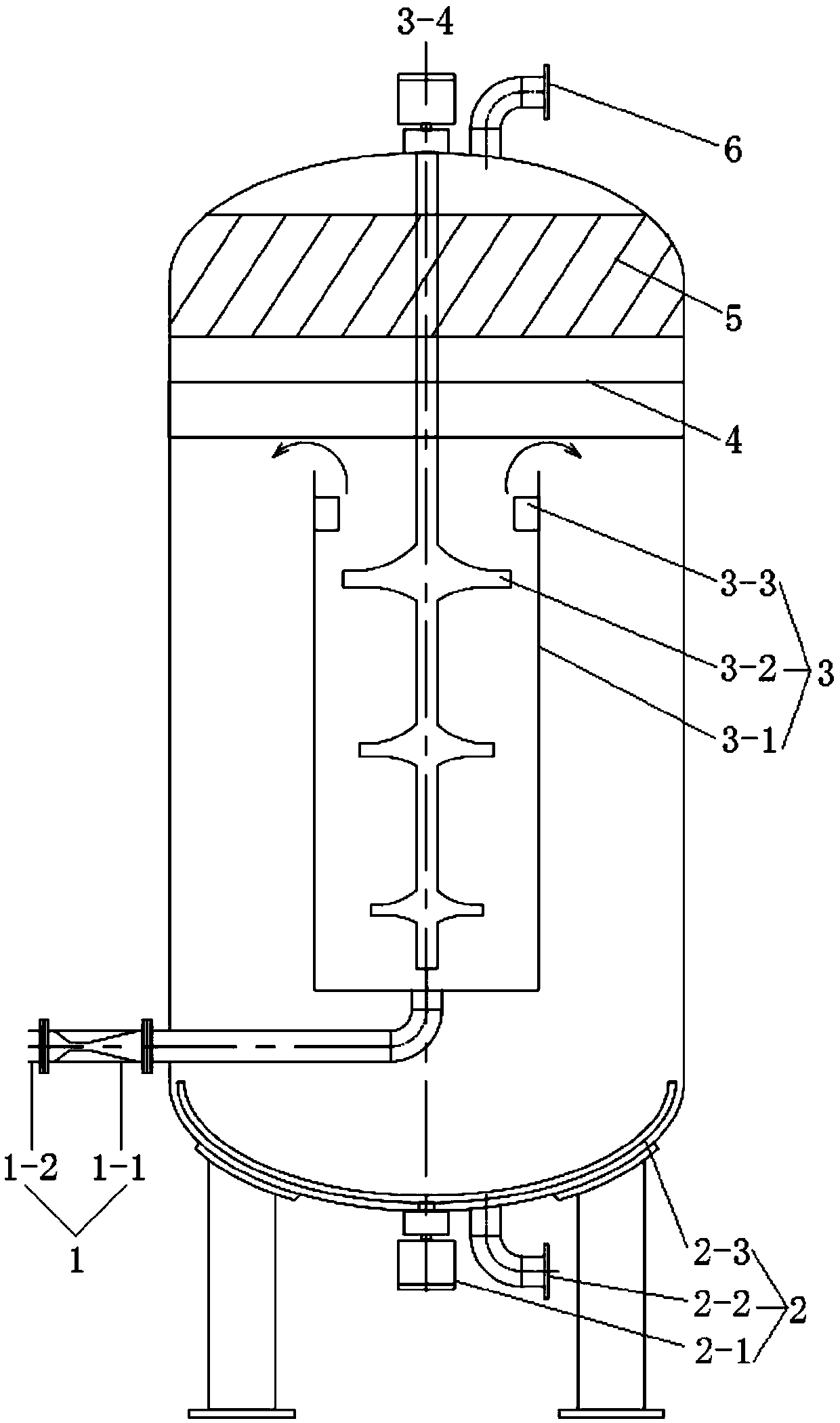

[0013] An integrated flocculation and sedimentation device, such as figure 1 As shown, it includes sewage and flocculant filling device 1, sludge discharge device 2 and flocculation reaction and stirring device 3, sewage and flocculant filling device 1 includes sewage and flocculant filling pump 1-1 and water inlet pipe 1-2 , the mud discharge device 2 includes a first motor 2-1, a mud discharge pipe 2-2 and a mud scraper 2-3, and the flocculation reaction and stirring device 3 includes a flocculation reaction bucket 3-1, an agitator, and an annular rectifier 3-3 and the second motor 3-4; when the integrated flocculation and sedimentation device is working, the tank body is seamlessly welded together by the top shell wall, the cylinder below the top shell and the bottom shell below the cylinder, The tank body is erected and fixed on the bracket by keeping its length direction perpendicular to the horizontal direction and being carried by the bracket. The shell wall arches dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com