Plant essential oil distilling extracting device

A technology for distillation and extraction of plant essential oils, applied in the directions of essential oils/spices, fat production, etc., to achieve the effects of improving the flavor and quality of essential oils, improving the quality of essential oils, and improving the yield of essential oils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

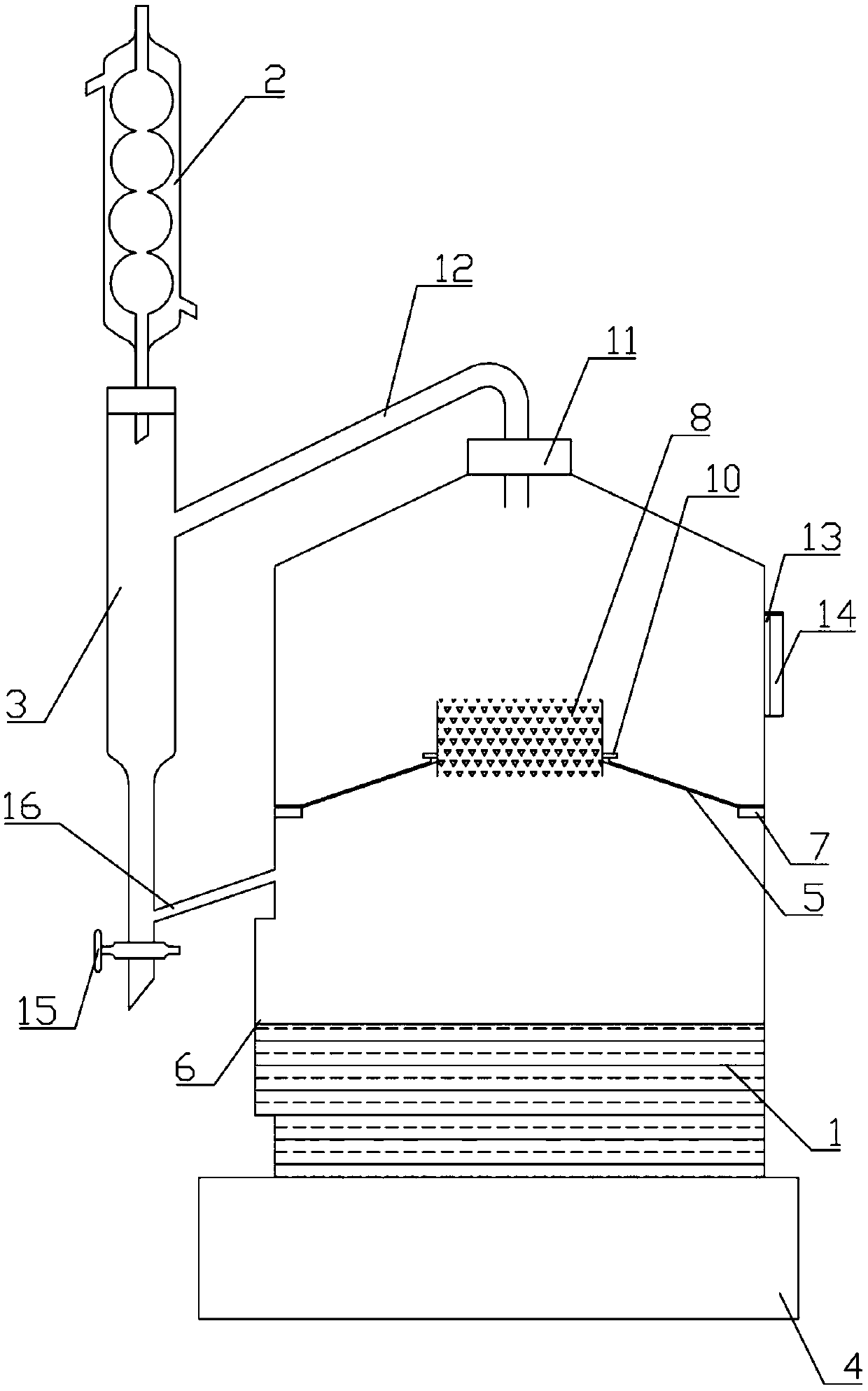

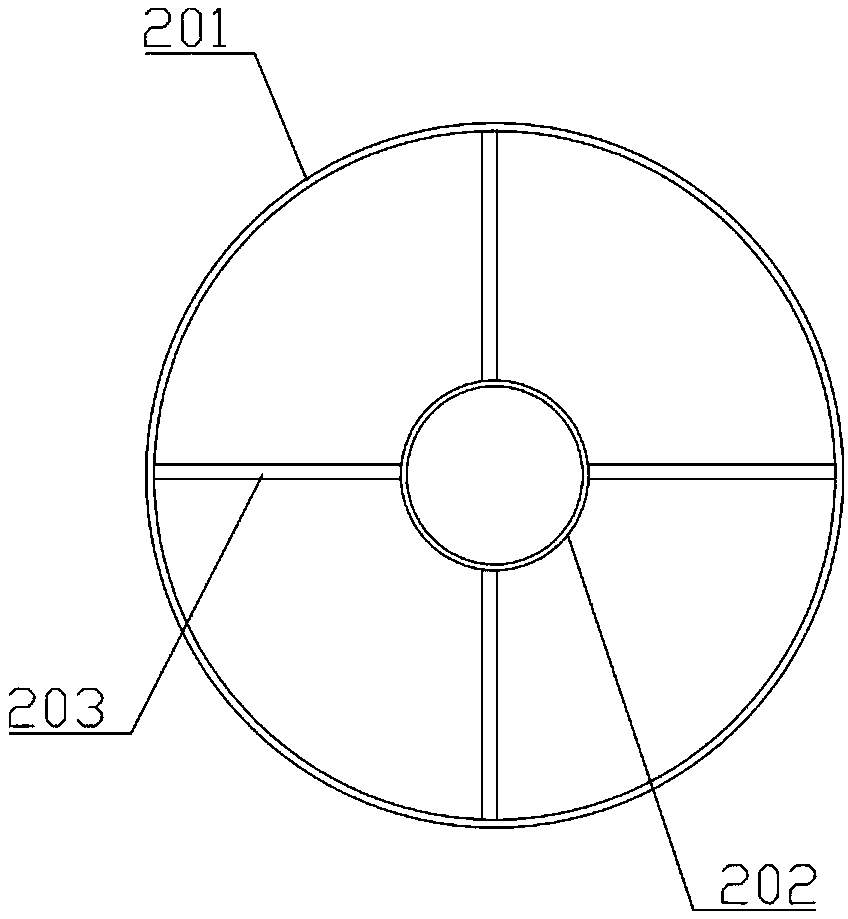

Embodiment 1

[0028] The plant essential oil distillation extraction device of this embodiment includes a distillation pot body 1, a condensation pipe 2, an oil-water separator 3, and a heating mechanism 4 for heating the distillation pot body 1. The heating mechanism 4 can be an induction cooker, an electric ceramic stove or an oil heater. Commonly used heating devices such as bathing pots are used to heat the water inside the still body 1 to evaporate to form water vapor. An installation ring 7 is integrally formed on the inner wall of the still body 1, and a sample tray support 5 is installed on the installation ring 7. The sample tray support 5 divides the interior of the still body 1 into two layers: a steam layer and a solvent layer. A sample tray 8 for containing distillation raw materials is installed on the support 5. The sample tray 8 is a cylinder with an open top and a screen installed at the bottom. The screen can prevent the leakage of the distillation material, and the mesh nu...

Embodiment 2

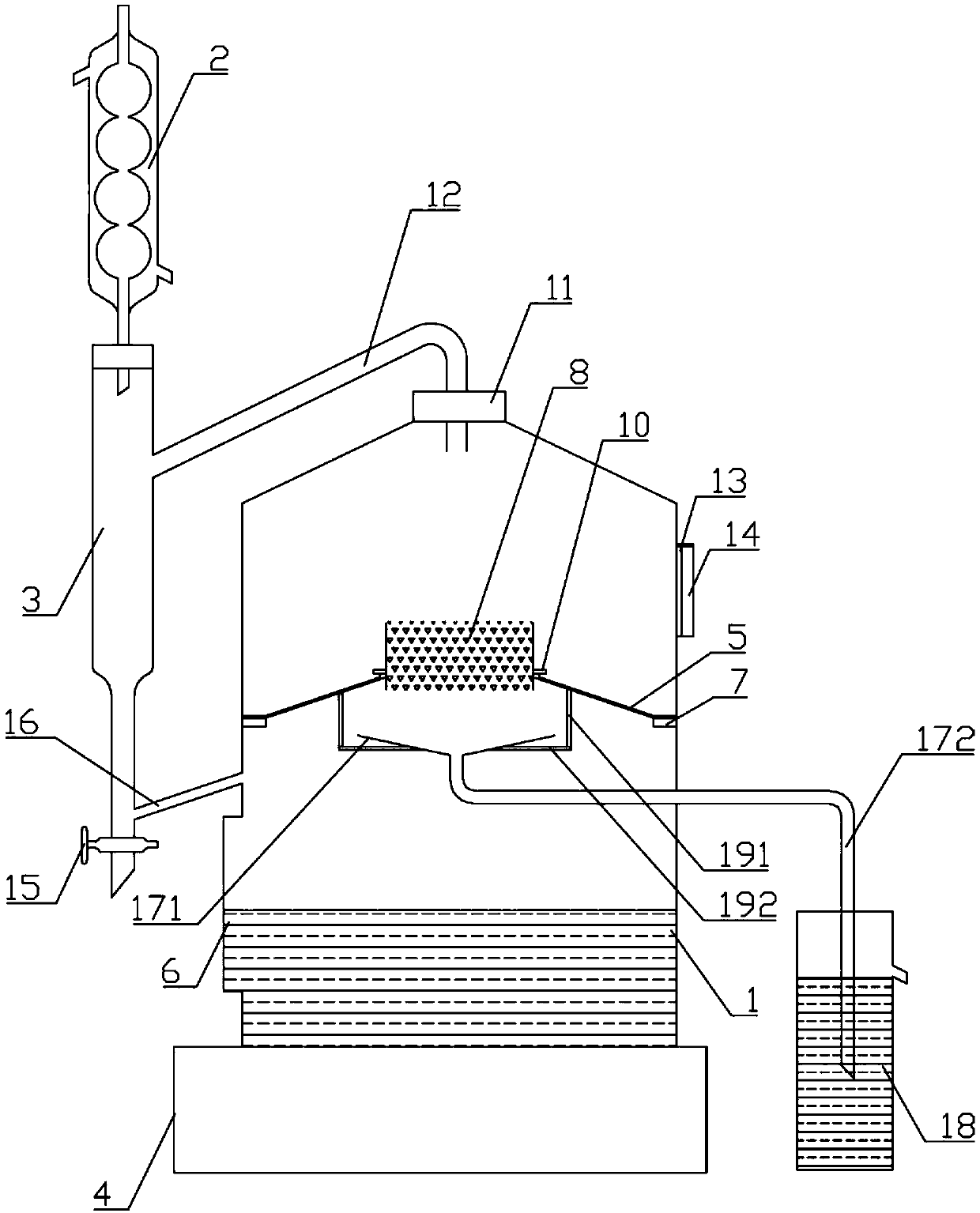

[0035] like figure 2 As shown, the plant essential oil distillation extraction device of this embodiment includes all the structures of Embodiment 1, and on the basis of the structure of Embodiment 1, a flow guide mechanism is added, and the flow guide mechanism includes a liquid receiver 171 and a drainage device connected to each other. The tube 172 and the liquid receiver 171 are located directly below the sample tray 8 and fully cover the bottom of the sample tray 8, and are used to receive the drops from the sample tray 8. The outlet end of the drainage tube 172 is connected with a liquid collection tube 18 for Collect the droplet that drops from the sample tray 8, the solution is housed in the liquid collection pipe 18, and the outlet end of the drainage pipe 172 is located below the liquid surface, for stabilizing the internal pressure of the distillation pot body 1, and the liquid collection pipe 18 can also be designed as a sealed The pipe body is equipped with a press...

Embodiment 3

[0039] like Figure 4 As shown, the plant essential oil distillation extraction device of this embodiment differs from Embodiment 2 in that the liquid receiver 171 is a cylinder with an open top and a conical bottom, and the drainage tube 172 is connected to the lowest point of the cylinder to collect The liquid all flows to the lowest part of cylinder body, and is exported through drainage tube 172. The stainless steel bracket used to support and fix the deflector mechanism in this embodiment also includes a support rod 191 and a mounting frame 192. The cylinder is installed on the mounting frame 192. The structure of the mounting frame 192 can be provided with the structure described in Embodiment 2, or it can be The truncated cone structure matched with the bottom of the cylinder can better support and install the cylinder. Similarly, one end of the support rod 191 is welded to the mounting frame 192 , and the other end can be welded to the sample tray support 5 , or can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com