Method for absorbing and extracting fragrant volatile of fresh flowers

A technology for the first fragrance and extraction of flowers, applied in the directions of essential oils/spices, fat production, etc., can solve the problems of low yield of essential oils, poor aroma of essential oils, and high labor consumption, so as to reduce investment and production costs, and reduce investment. , the effect of improving the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

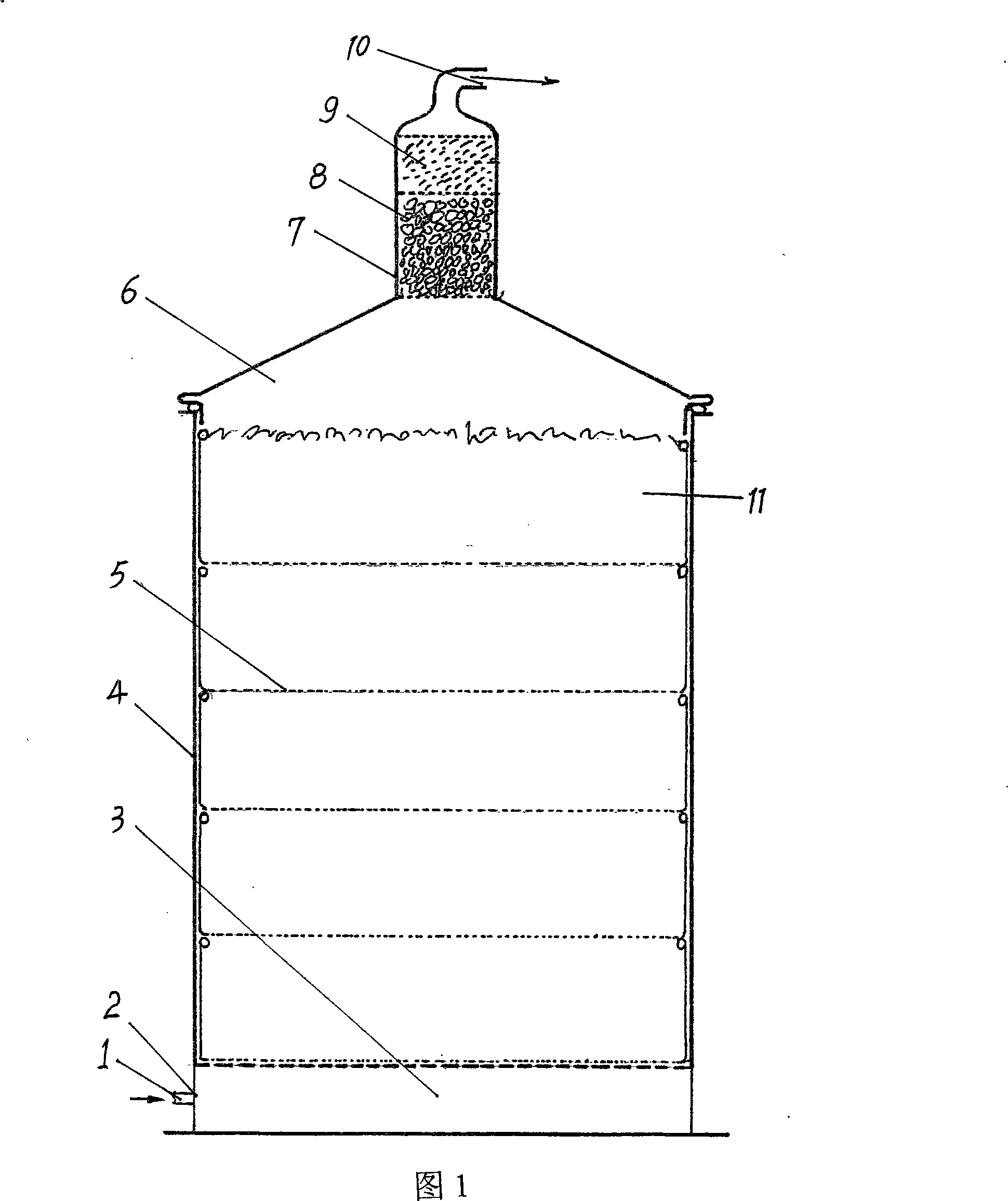

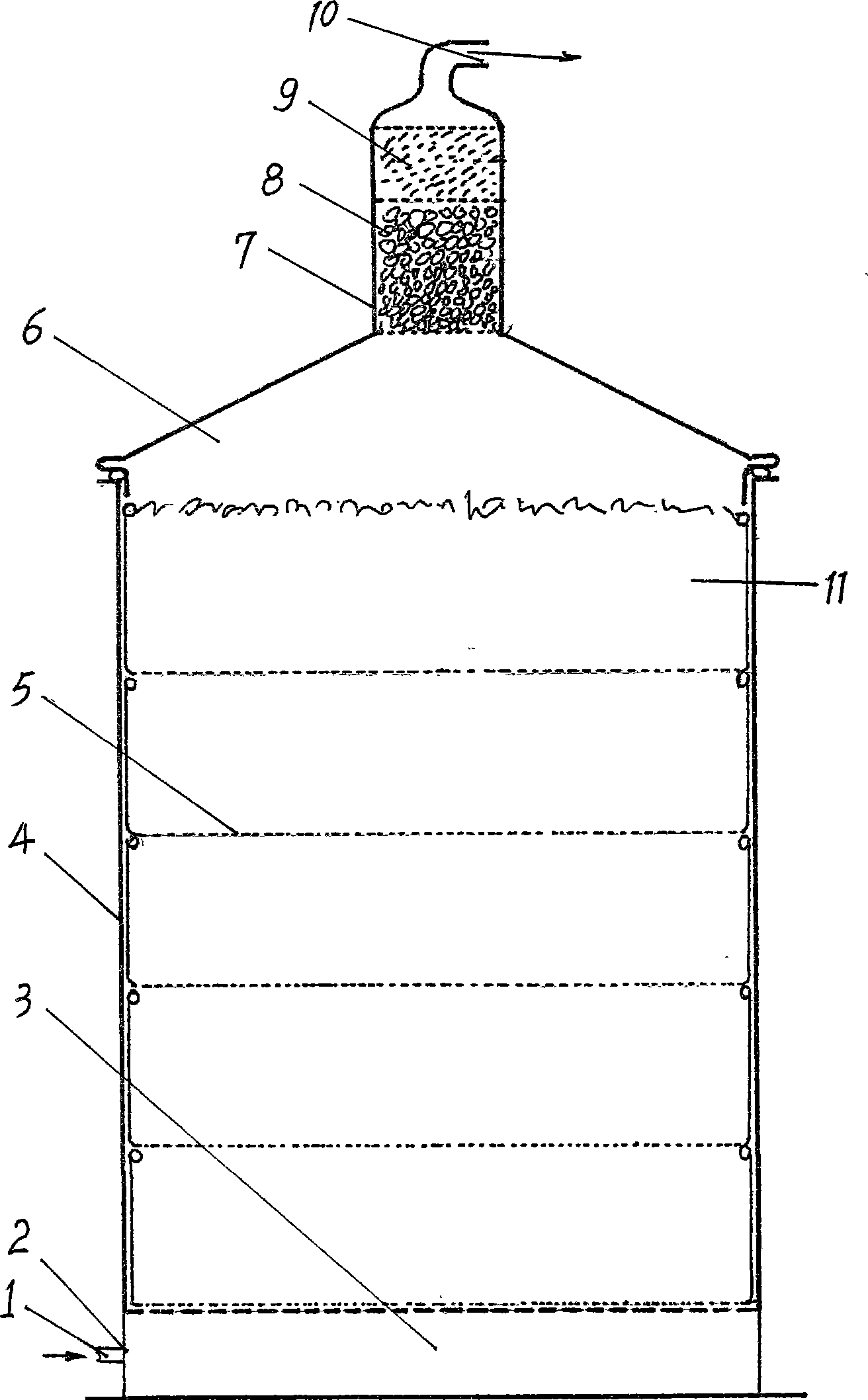

[0022] A, the fresh gardenia layering is flatly spread on the fresh flower separation screen 5 in the cylindrical housing 4, constitutes the fresh flower layer 11, and the amount of 25 grams per kilogram of fresh flowers is used in the lower part of the adsorption column 7 at the top of the housing 4 The molecular sieve layer 8 is placed, and the active carbon layer 9 is placed with an amount of 10 grams per kilogram of fresh flowers on the molecular sieve layer 8;

[0023] B. Humid air with a humidity of 75% enters from the lower part of the flower layer 11 through the air supply pipe 1, the air inlet 2 and the channel 3 at the bottom of the housing 4;

[0024] C. From the air outlet 10 on the top of the adsorption column 7 on the upper part of the housing 4, use a vacuum pump from bottom to top, and pump air for 20 hours at a flow rate of 50 liters / hour, normal temperature, and a vacuum of -18 to -25 mmHg. , let the moist air pass through the fresh flower layer 11, let the v...

Embodiment 2

[0028] A, fresh roses are spread flat on the fresh flowers separating screen 5 in the cylindrical housing 4 to form the fresh flower layer 11, and the upper part in the adsorption column 7 at the top of the housing 4 is used in an amount of 35 grams per kilogram of fresh flowers The molecular sieve layer 8 is placed, and the active carbon layer 9 is placed with an amount of 20 grams per kilogram of fresh flowers on the molecular sieve layer 8;

[0029] B. Humid air with a humidity of 75% enters from the lower part of the flower layer 11 through the air supply pipe 1, the air inlet 2 and the channel 3 at the bottom of the housing 4;

[0030] C. From the air outlet 10 on the top of the adsorption column 7 on the upper part of the housing 4, use a vacuum pump from bottom to top, and pump air for 26 hours at a flow rate of 40 liters / hour, normal temperature, and a vacuum of -18 to -25 mmHg. , let the moist air pass through the fresh flower layer 11, let the volatile matter in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com