Method for concrete pouring in arch bridge steel pipe, device and application thereof

A technology for concrete and concrete delivery pumps, applied in arch bridges, bridges, buildings, etc., can solve the problems of unguaranteed concrete compactness and low operating efficiency, and achieve the effect of unguaranteed concrete compactness, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

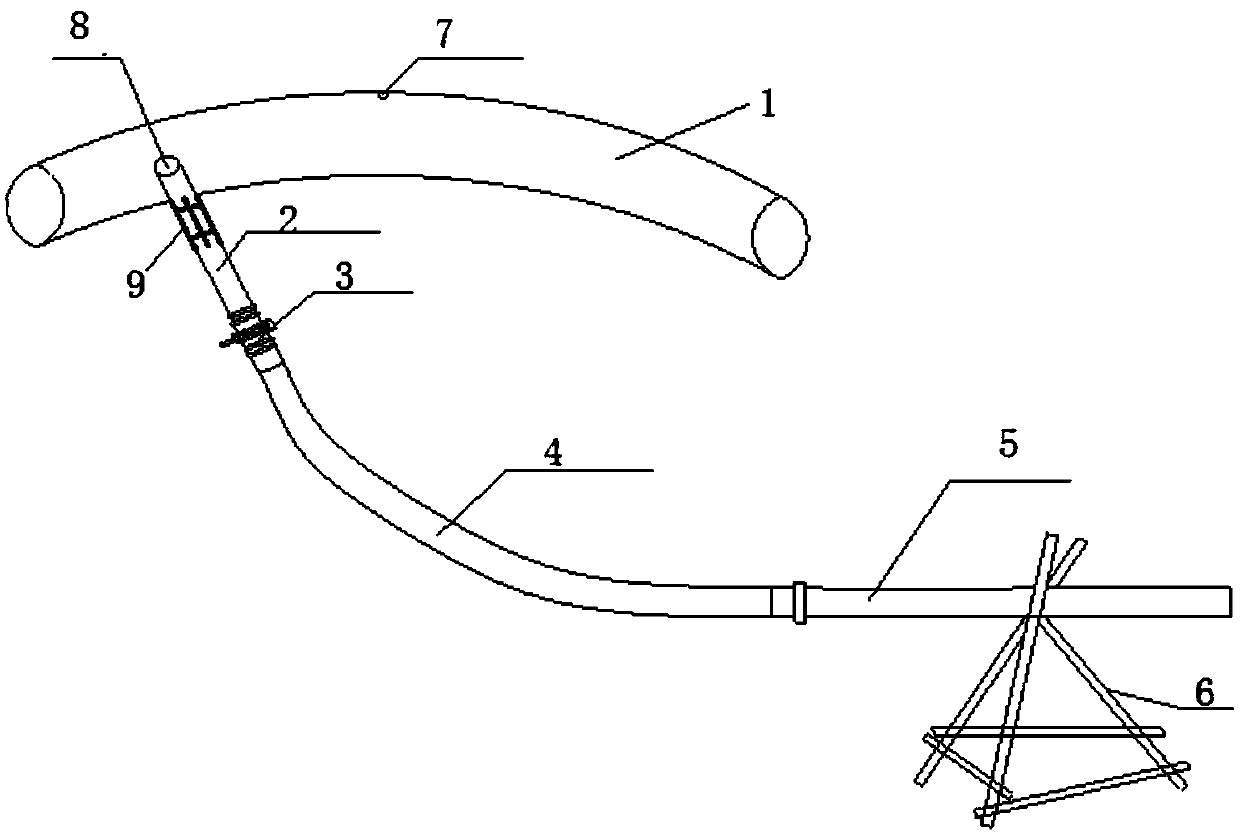

[0041] This embodiment discloses a concrete pouring device in a steel pipe for an arch bridge, including:

[0042] Steel pipe 1, the two ends of the steel pipe 1 are fixed on the bridge foundation, and the top surface of the steel pipe 1 is provided with an overflow hole 7;

[0043] A feeding pipe 2, the upper end of the feeding pipe 2 is half embedded in the end of the steel pipe 1;

[0044] A stop structure 3, located at the lower end of the feed pipe 2;

[0045] A high-pressure pipe 4 is connected to the flow-stopping structure 3;

[0046] A pump pipe 5, one end of the pump pipe 5 is connected to the high-pressure pipe 4, and the other end is connected to the concrete delivery pump;

[0047] A stabilizing bracket 6, located below the pump tube 5;

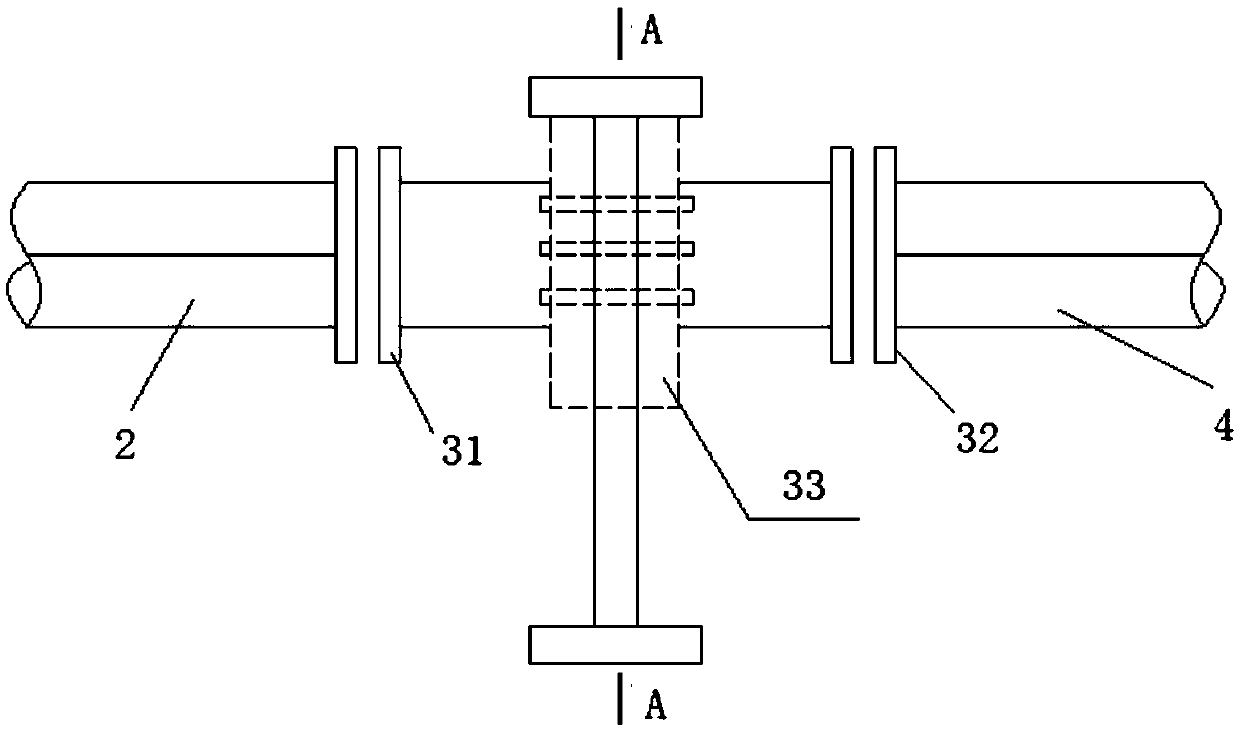

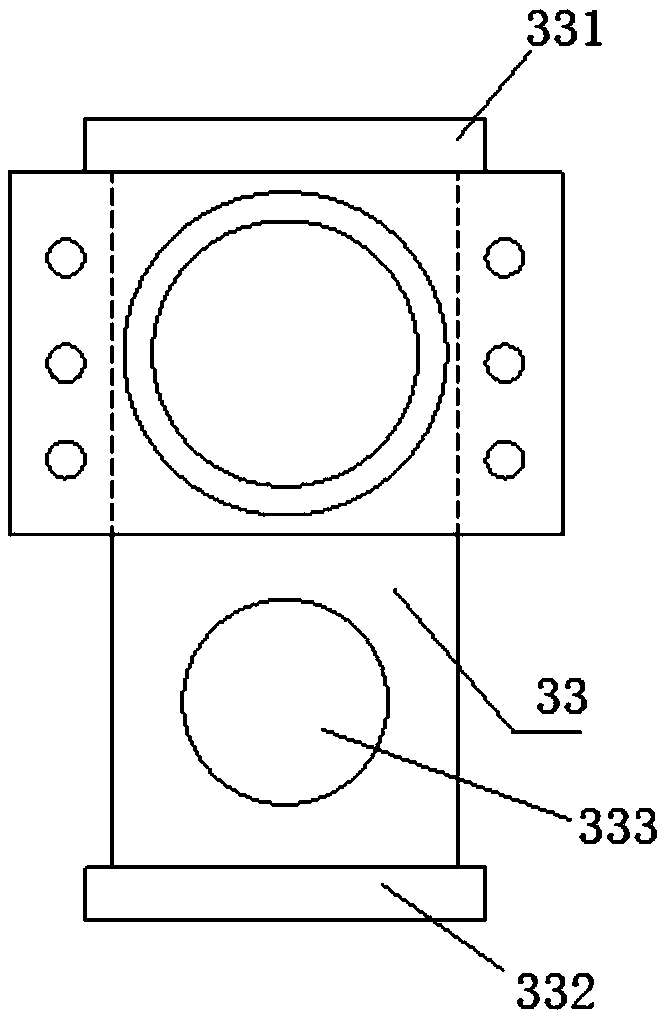

[0048] Wherein, the stop structure 3 includes a front joint 31 and a rear joint 32, the front joint 31 is connected to the feed pipe 2, and the rear joint 32 is connected to the high-pressure pipe 4;

[0049] The front joint ...

Embodiment 2

[0058] This embodiment discloses a method for pouring concrete in a steel pipe using the concrete pouring device in a steel pipe for an arch bridge disclosed in Embodiment 1, including the following steps:

[0059] S1: Concrete is transported after the concrete pouring device in the steel pipe is built;

[0060] S2: Stop pumping after the concrete in the steel pipe overflows, and close the flow-stopping structure;

[0061] S3: cleaning the remaining concrete on the steel pipe;

[0062]S4: After the final setting of the concrete, remove the flow-stop structure, cut off the feed pipe, repair the cut of the feed pipe and the overflow hole.

[0063] The concrete steps of described S2 are:

[0064] S21: after the pouring of the concrete delivery pump, control the pump pressure for 2-3 minutes;

[0065] S22: Remove the high-pressure pipe after the movable valve plate closes the channel of the feed pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com