Rotor visual measuring machine

A visual measurement and rotor technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of low production efficiency, low recognition accuracy, complex structure, etc., and achieve high positioning accuracy, high measurement accuracy, and measurement high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

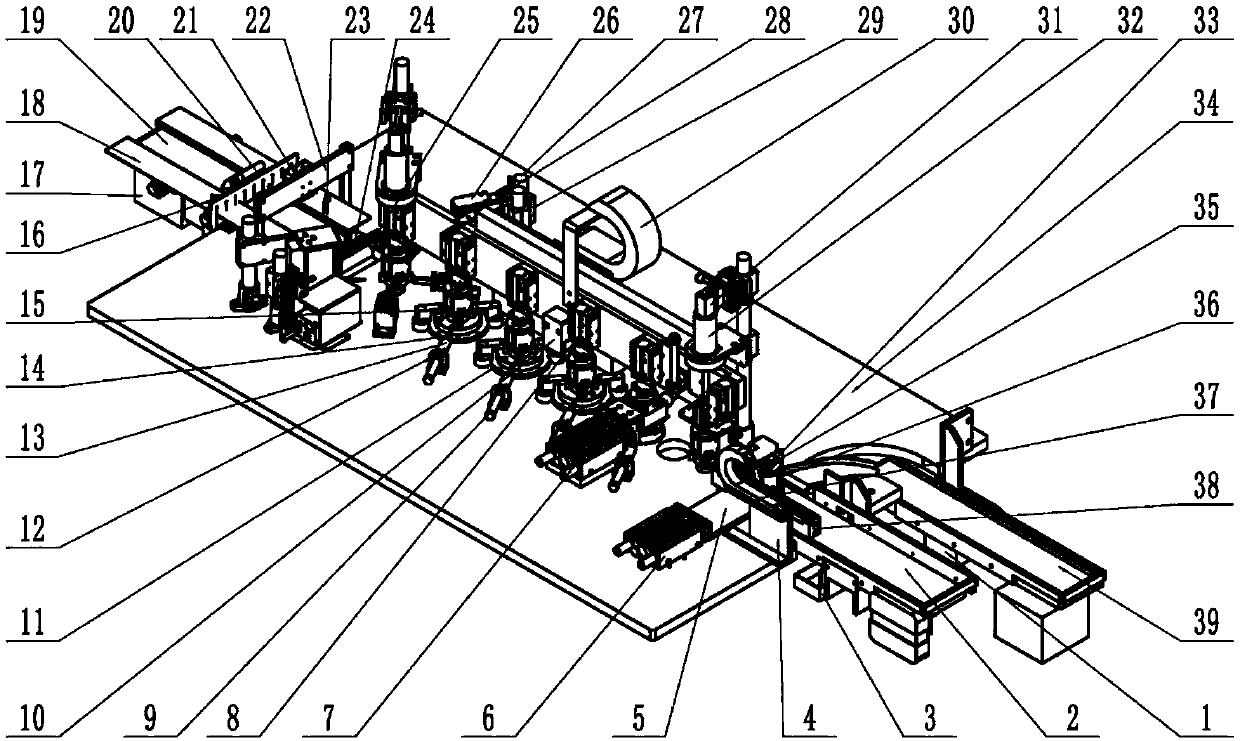

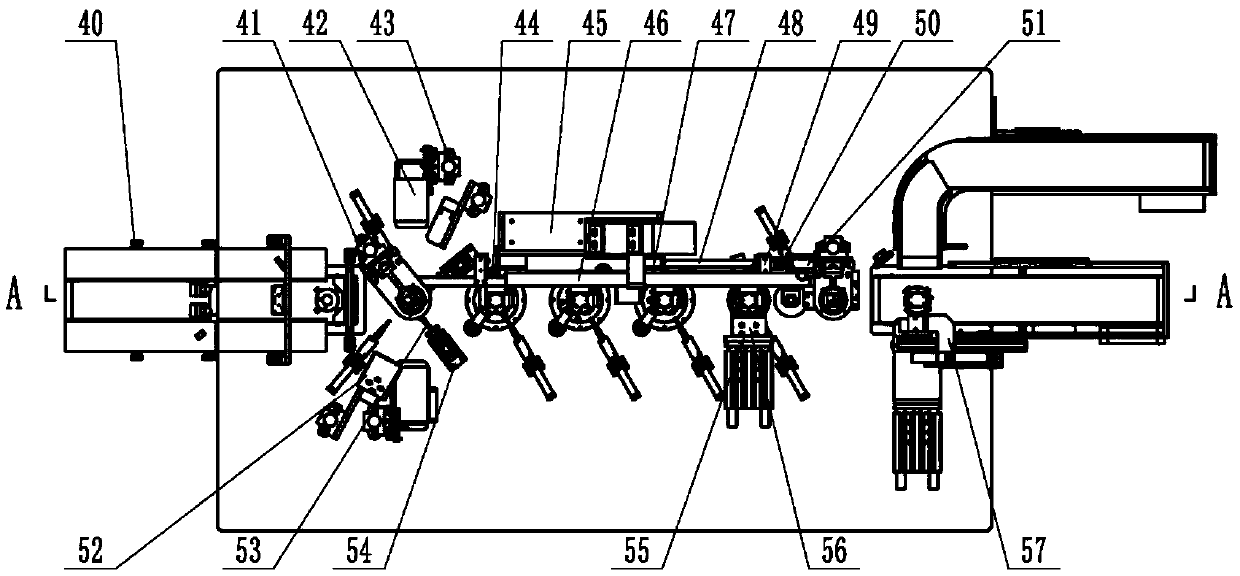

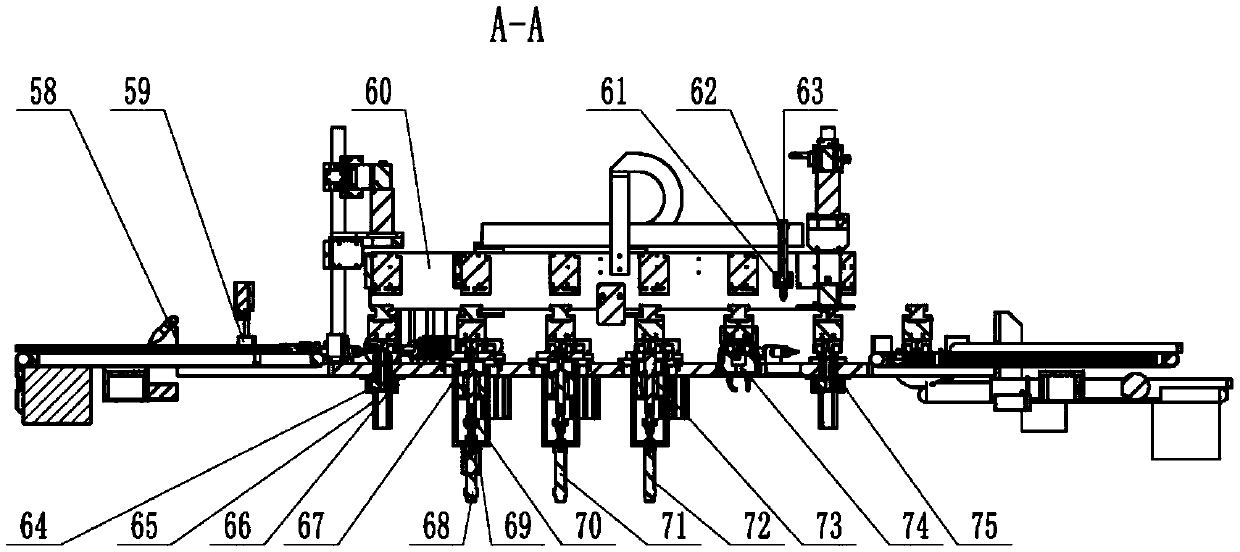

[0038] Such as Figure 1-4 As shown, a rotor vision measuring machine can detect various types of rotors. The type of the rotor is processed by the visual processing device 78 at the first station during detection. The detection steps of any type of rotor are taken as an example below.

[0039] A rotor vision measuring machine, comprising: a transmission component 76, a material delivery component 77, a vision processing device 78, a positioning component 79, a rotor turntable component 80, an inner hole measurement component 81, a blind hole measurement component 82, a height measurement component 83, a marking Assembly 84, pushing assembly 85;

[0040] The conveying assembly 76 includes a feeding assembly and a blanking assembly, which are respectively installed at both ends of the equipment; one end of the feeding assembly is equipped with a feeding assembly, and the feeding assembly and the transporting assembly 77 are installed together; multiple detection stations are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com