Device for testing rigidity of semi-rigid bearing

A semi-rigid and bearing technology, which is applied in the field of devices for testing the stiffness of semi-rigid bearings, can solve the problems of inaccurate detection accuracy, inability to fully reflect the stiffness performance and offset of semi-rigid bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

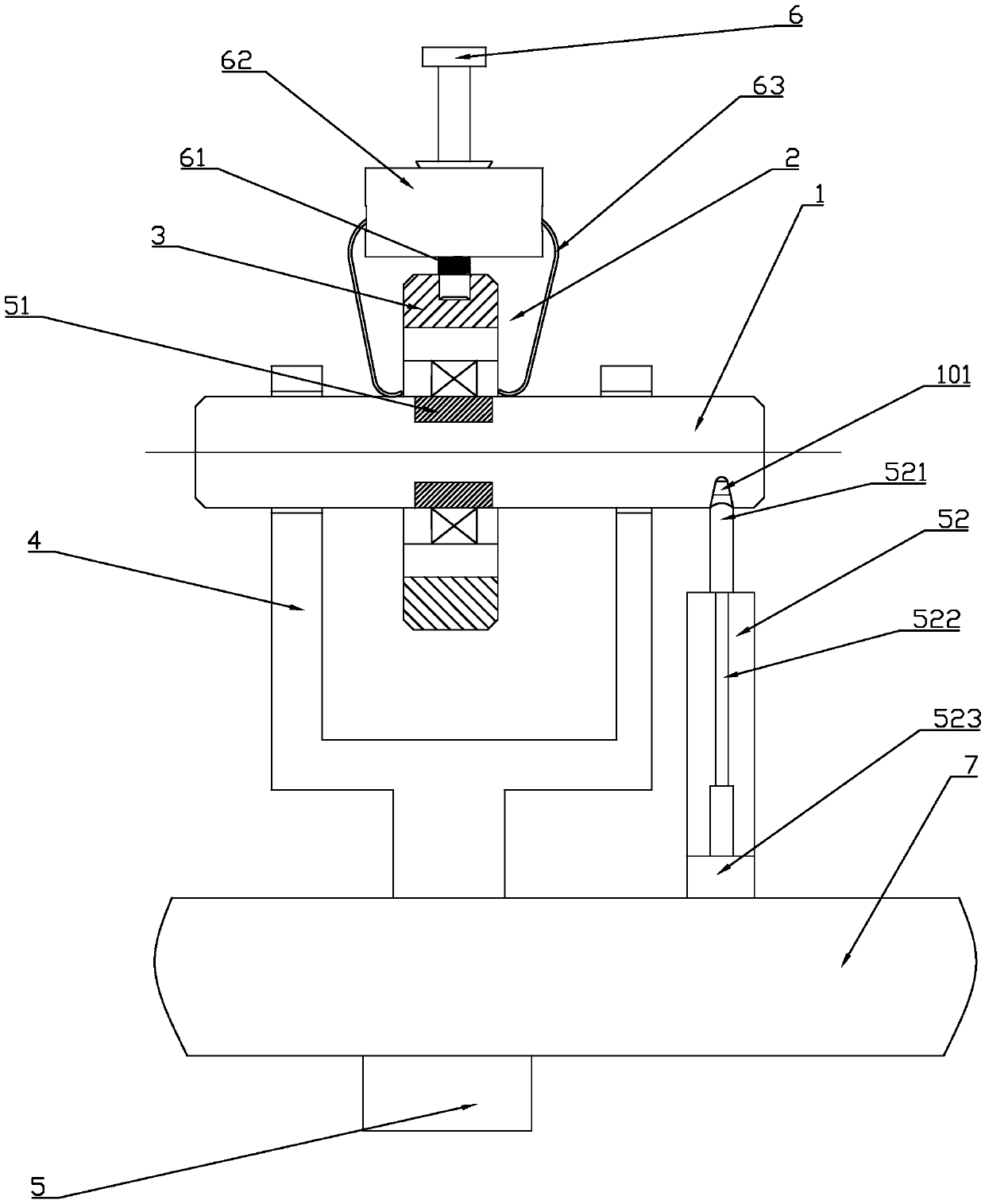

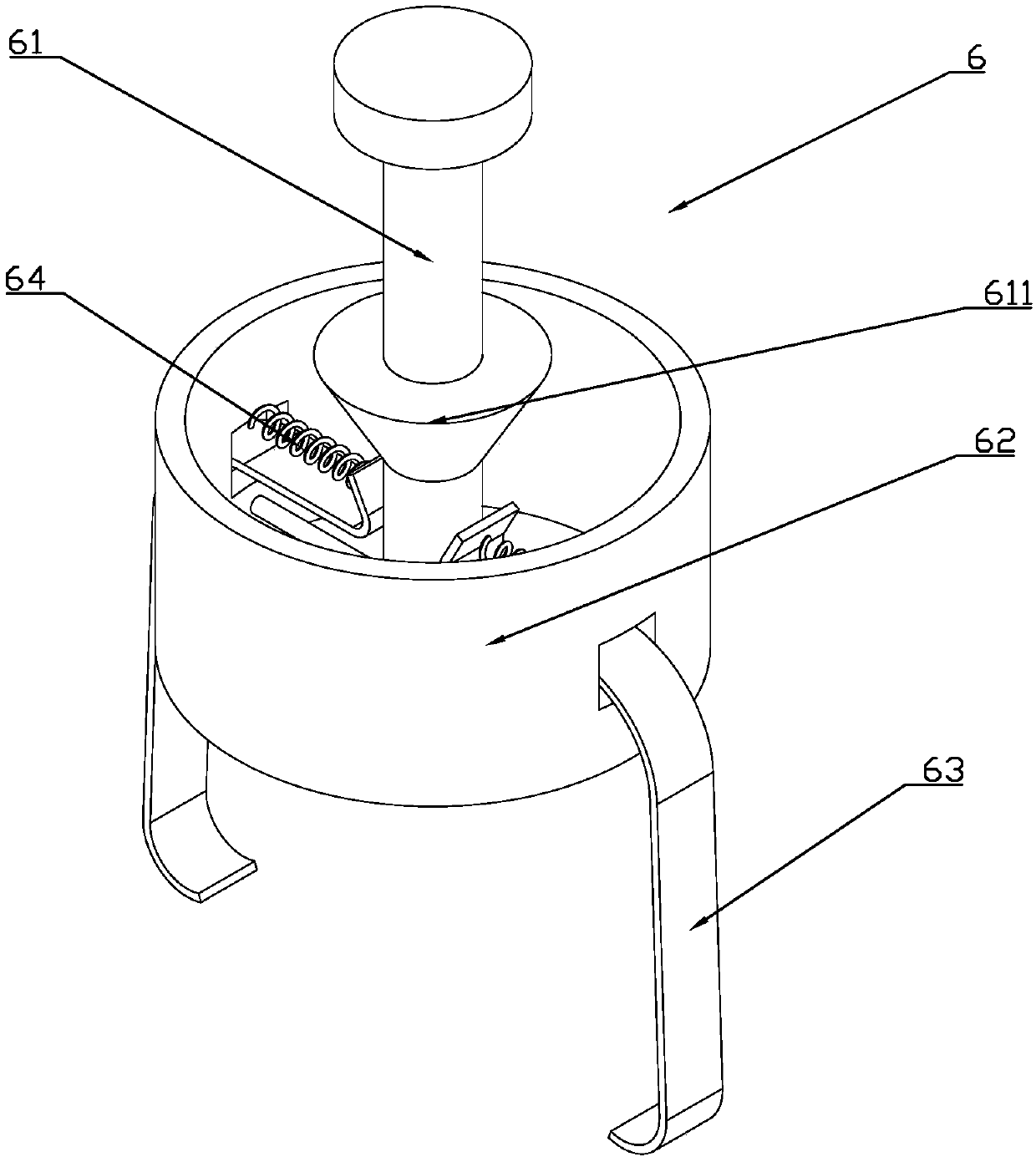

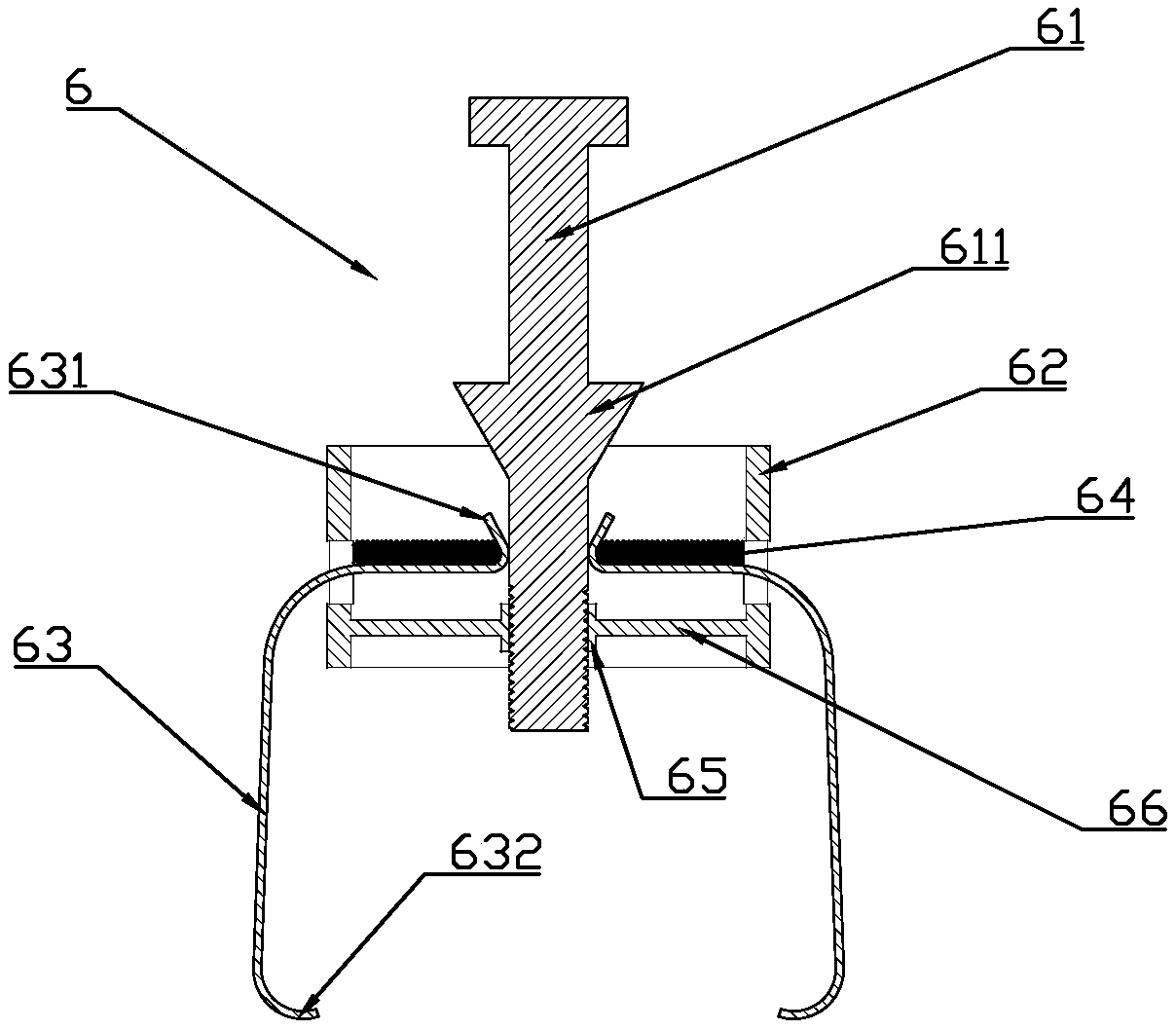

[0018] Depend on Figure 1 to Figure 4 It can be seen that the present invention discloses a device for detecting the stiffness of a semi-rigid bearing, which includes a driving member and a fixed assembly, a test shaft 1 is arranged between the driving member and the fixed assembly, and a test shaft 1 is provided with a Station 2, the station to be tested is provided with a fixed shell 3 for installing the bearing to be tested, and the drive member includes a connecting rod 4 arranged at both ends of the test shaft 1 and a device for driving the connecting rod 4 to slide. The hydraulic cylinder 5, the connecting rod 4 is engaged with the test shaft 1, the connection between the test shaft 1 and the station 2 to be tested is provided with a pressure sensor 51, and the test shaft 1 is provided with a pressure sensor 51 for detecting the displacement of the test shaft 1. The telescopic displacement sensor 52, the fixing assembly includes a fixing fixture 6, and the fixing fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com