Energy imaging system and application thereof in motor device fault detection method

A technology of electrical equipment and equipment, which is applied in the field of electrical equipment fault detection, can solve the problems of training classification model generality and accuracy limitations, diagnostic data can not be fully utilized, etc., and achieve fast calculation speed, improved accuracy, and accurate collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but it should be noted that the examples do not limit the protection scope of the present invention.

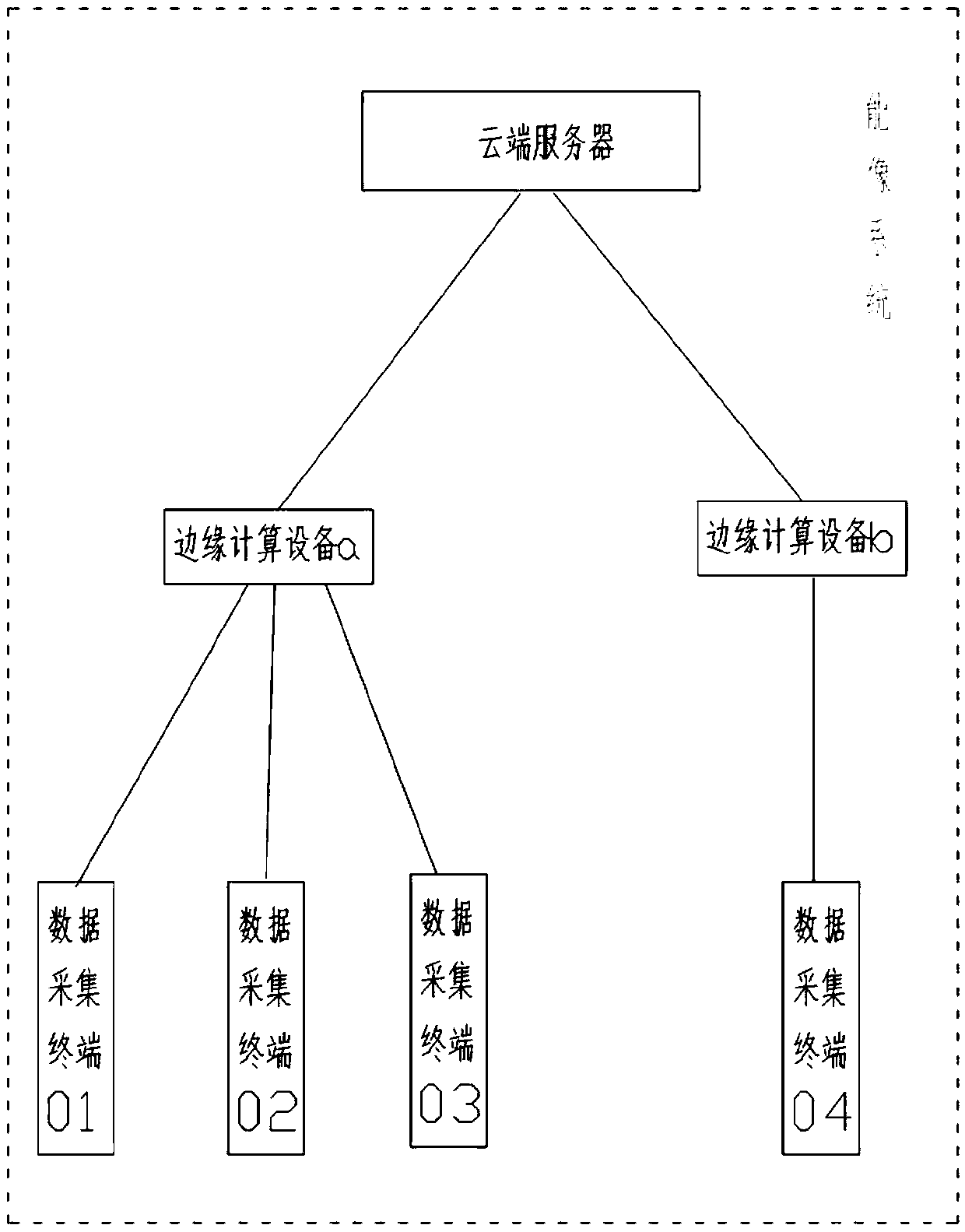

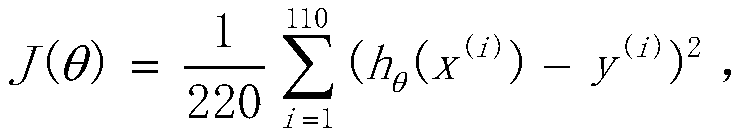

[0022] In this embodiment, an imaging system includes several acquisition device terminals, several edge computing devices, a cloud server, and several motor devices; each edge computing device in the several edge computing devices is connected to At least one collection device terminal is connected through a WIFI network, wherein each collection device terminal is electrically connected with a motor device; the cloud server is connected with each edge computing device through a WIFI network. The motor equipment fault detection method using the imaging system and the deep learning algorithm is as follows: the acquisition equipment terminal collects the real-time current, voltage, power and power factor electric energy parameters of the electrical equipment to be detected electrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com