Moss table manufacturing process

A manufacturing process, moss table technology, applied in the field of tables, can solve the problems of unusable wooden boards, easy rot of wooden boards, waste of resources, etc., to achieve the effect of expanding the scope of application and practicability, beautifying the aesthetics, and preventing subsequent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

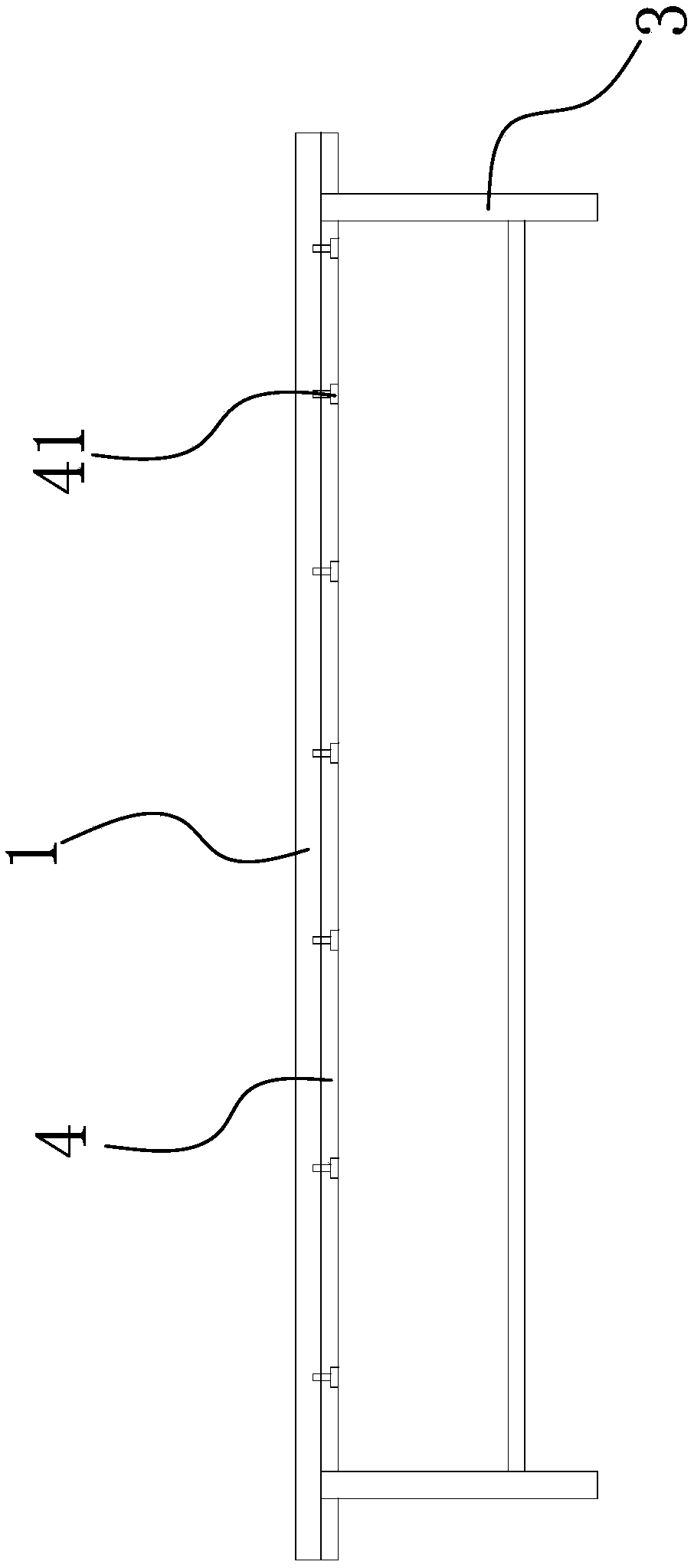

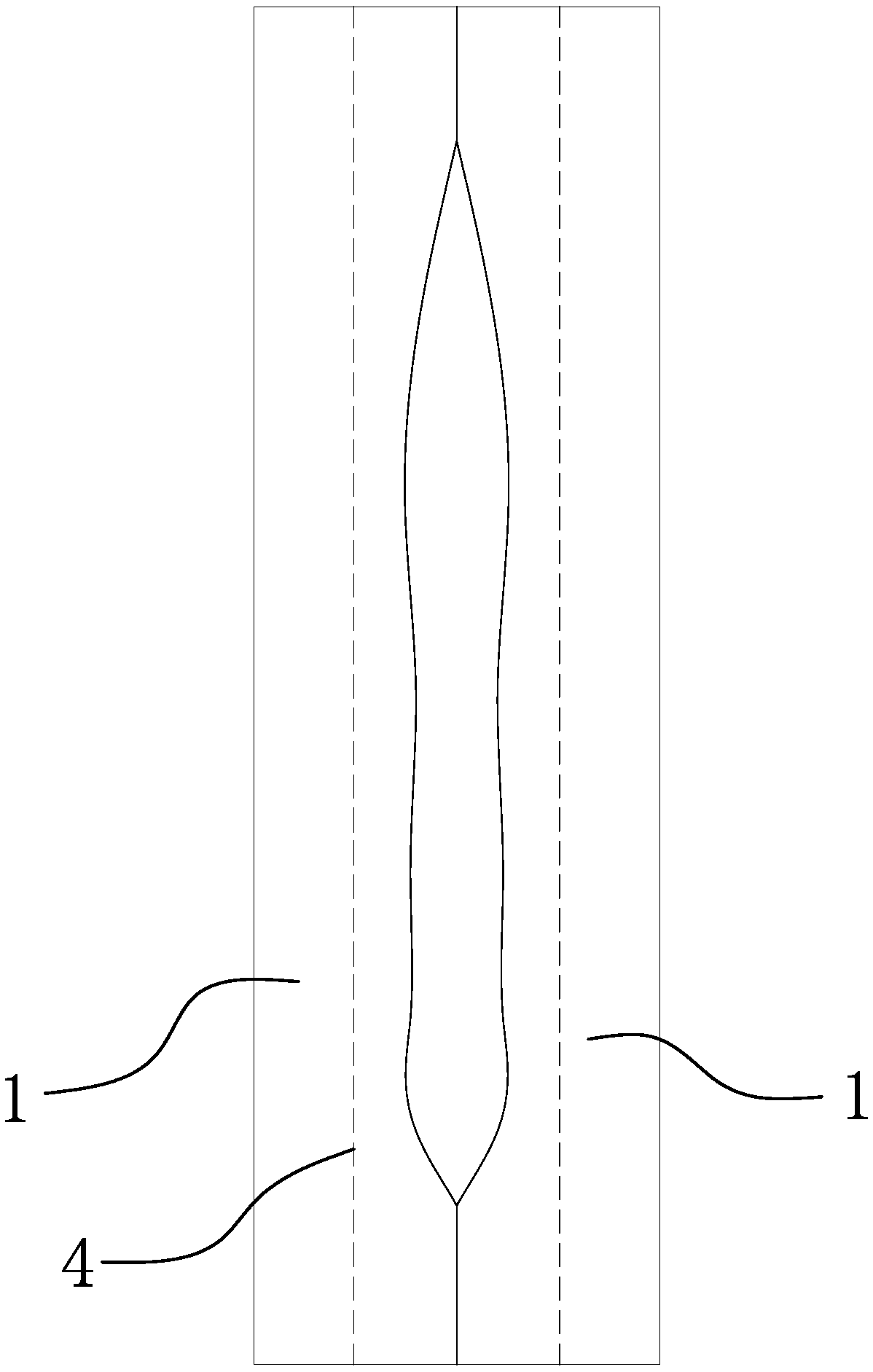

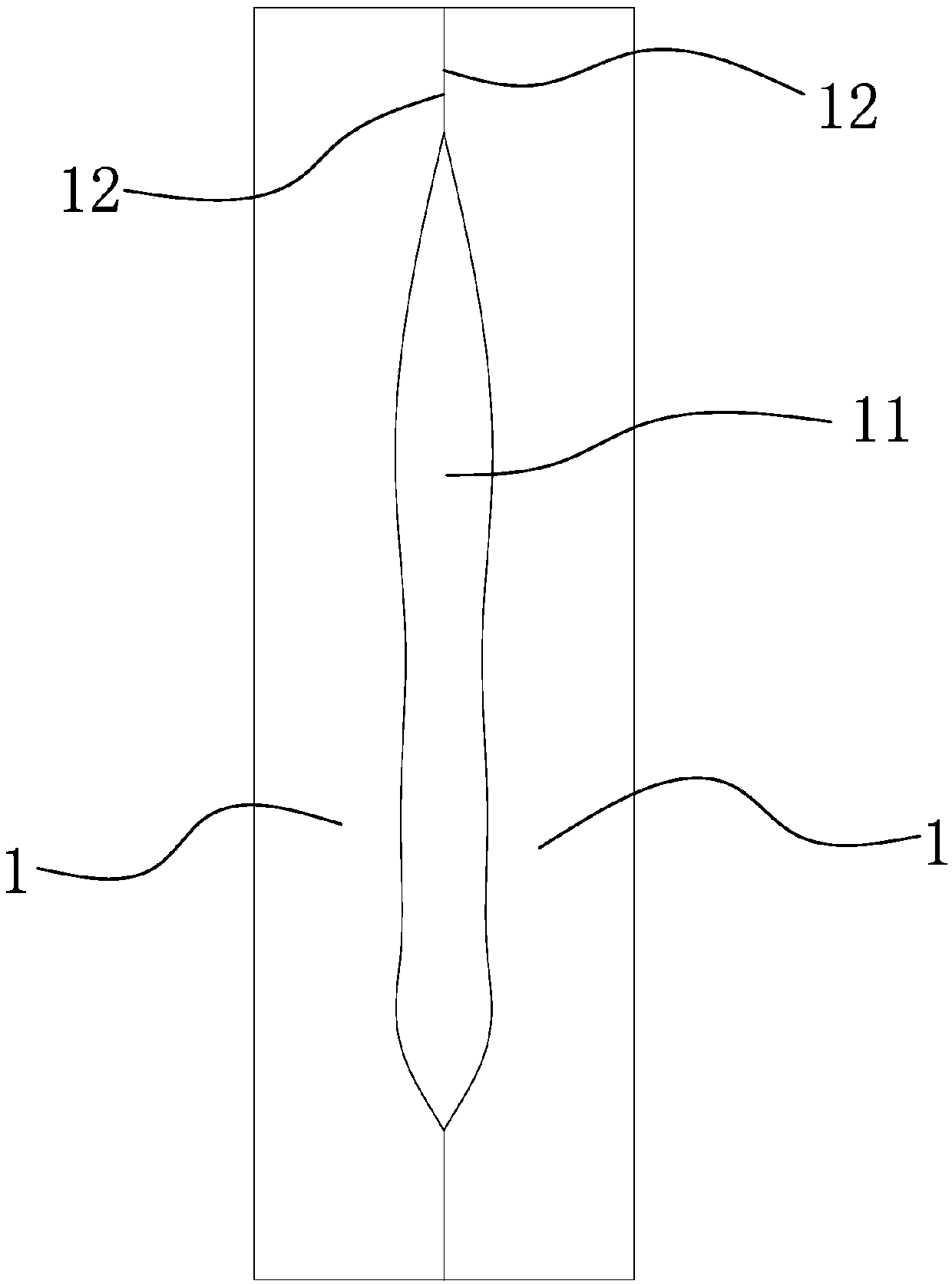

[0057] like Figure 1-7 and Figure 9 as shown,

[0058] The manufacturing process of this moss table comprises the following steps:

[0059] S1, material selection, select the wood block 1 that water resistance is good for use, on the upper surface of the wood block 1 there are planting grooves 11 distributed along the length direction of the wood block 1, optimization scheme, the wood block 1 of the present embodiment has two, two The wooden blocks 1 are parallel to each other and the above-mentioned planting groove 11 is formed between the inner sides of the two wooden blocks 1 facing each other.

[0060] The notch of the planting groove 11 is provided with an inclined slope 13 inclined inwardly and downwardly.

[0061] Secondly, at least one stainless steel plate 4 is connected to the inner lower surface of the two wooden blocks 1, and the two sides of the stainless steel plate 4 are fixed on the inner lower surface of the wooden block 1 by a number of stainless steel n...

Embodiment 2

[0084] The structure and working principle of this embodiment are basically the same as those of Embodiment 1, the only difference is that:

[0085] like Figure 8 As shown, described block 1 is made of a whole piece of wood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com