Tubular titanium dioxide nanocomposite SB adsorbent loaded with zirconium dioxide and ferric oxide and its preparation method and application

A nano-composite, nano-titanium dioxide technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problems of complex preparation process, limited application, and difficulty in separating adsorbents from water bodies. , to achieve the effect of simple preparation process, low cost and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

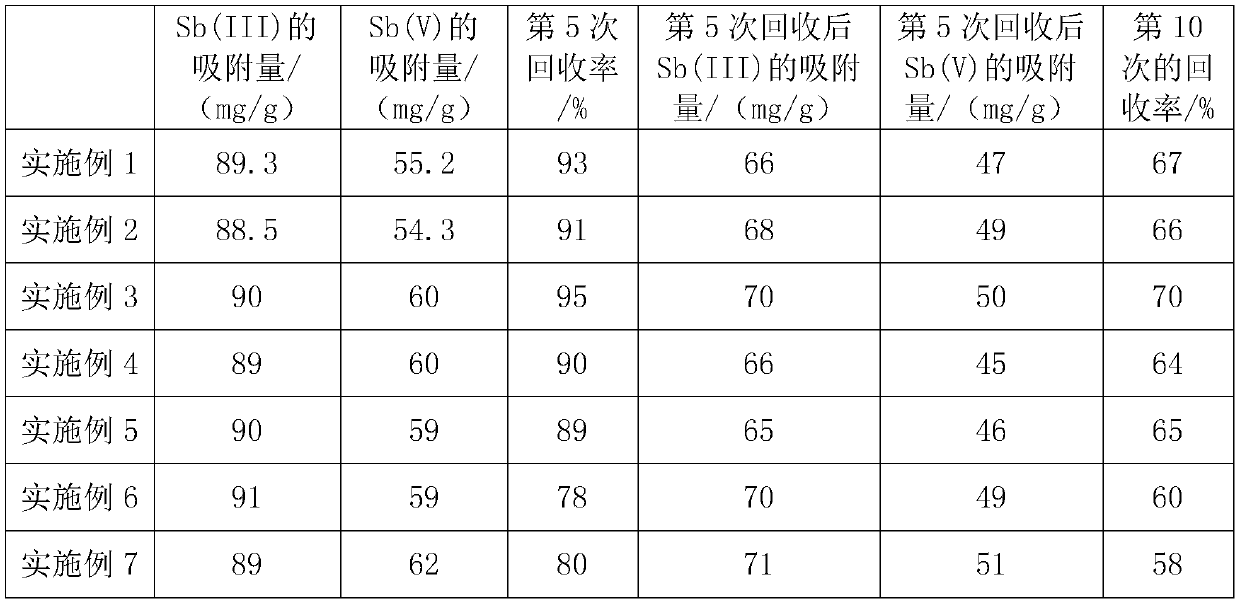

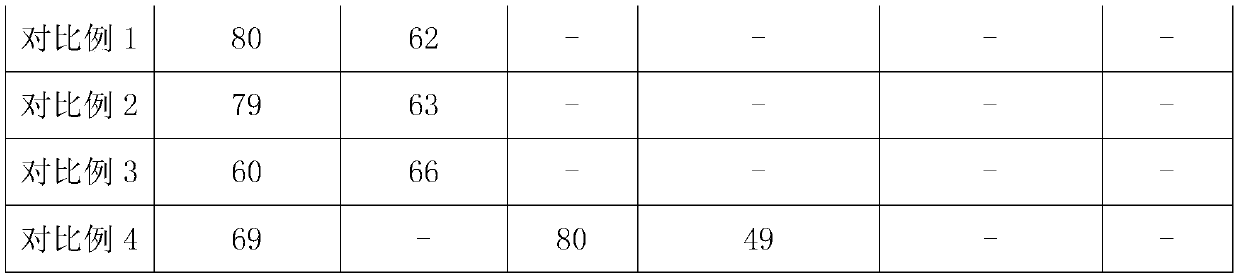

Examples

Embodiment 1

[0046] (1) Preparation of nano-titanium dioxide tubes: anatase TiO 2 Nanoparticles were dispersed into 8M sodium hydroxide solution, the ratio of the two was 5g:80mL, electromagnetically stirred for 1.5h, then transferred to a polytetrafluoroethylene autoclave, and reacted at 120°C for 24h to obtain a white solid Wash the product with deionized water until the pH value of the supernatant is neutral, then soak in 0.6M hydrochloric acid solution for 3 hours, then wash the protonated white solid product with deionized water to pH = 7, and finally, dry it at 95°C dry to obtain nano-titanium dioxide tubes;

[0047] (2) Preparation of stock solution: 3 parts by mass of zirconium chloride octahydrate (ZrOCl 2 ·8H 2 O) be dissolved in the mixed solution of N,N-dimethylformamide (DMF) and ethanol that mass ratio is 0.5:1, configure the stock solution 1 of 13 mass parts; FeCl 3 ·6H 2 O, FeCl 2 4H 2 O was dissolved in deionized water deoxygenated with nitrogen in advance, and then ...

Embodiment 2

[0051] (1) Preparation of nano-titanium dioxide tubes: anatase TiO 2 Disperse nanoparticles into 12M sodium hydroxide solution, the dosage ratio of the two is 1g:150mL, transfer it to a polytetrafluoroethylene autoclave after electromagnetic stirring for 3 hours, and heat and press at 150°C for 10 hours to obtain a white solid product Wash with deionized water until the pH value of the supernatant is neutral, then soak in 0.2M hydrochloric acid solution for 8 hours, then wash the protonated white solid product with deionized water to pH = 7, and finally dry it at 70°C , to obtain nano-titanium dioxide tubes;

[0052] (2) Preparation of stock solution: 1 mass part of zirconium chloride octahydrate (ZrOCl 2 ·8H 2 O) be dissolved in the mixed solution of N,N-dimethylformamide (DMF) and ethanol that mass ratio is 3:1, configure the stock solution 1 of 13 mass parts; FeCl 3 ·6H 2 O, FeCl 2 4H 2 O was dissolved in deionized water deoxygenated with nitrogen in advance, and then...

Embodiment 3

[0056] (1) Preparation of nano-titanium dioxide tubes: anatase TiO 2 Nanoparticles were dispersed into 10M sodium hydroxide solution, the ratio of the two was 3g:100mL, electromagnetically stirred for 2h, then transferred to a polytetrafluoroethylene autoclave, and reacted at 130°C for 18h to obtain a white solid product Wash with deionized water until the pH value of the supernatant is neutral, then soak in 0.5M hydrochloric acid solution for 5 hours, then wash the protonated white solid product with deionized water to pH = 7, and finally dry it at 90°C , to obtain nano-titanium dioxide tubes;

[0057] (2) Preparation of stock solution: 2 parts by mass of zirconium chloride octahydrate (ZrOCl 2 ·8H 2 O) be dissolved in the mixed solution of N,N-dimethylformamide (DMF) and ethanol that mass ratio is 1:1, configure the stock solution 1 of 13 mass parts; FeCl 3 ·6H 2 O, FeCl 2 4H 2 O was dissolved in deionized water deoxygenated with nitrogen in advance, then concentrated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com