Coix seed processing production line and processing method

A barley and barley production line technology, applied in application, grain processing, grain milling, etc., can solve the problems of large nutrient loss, long drying time of barley, more moldy barley, etc., so as to achieve less loss of nutrients and avoid Short storage time, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

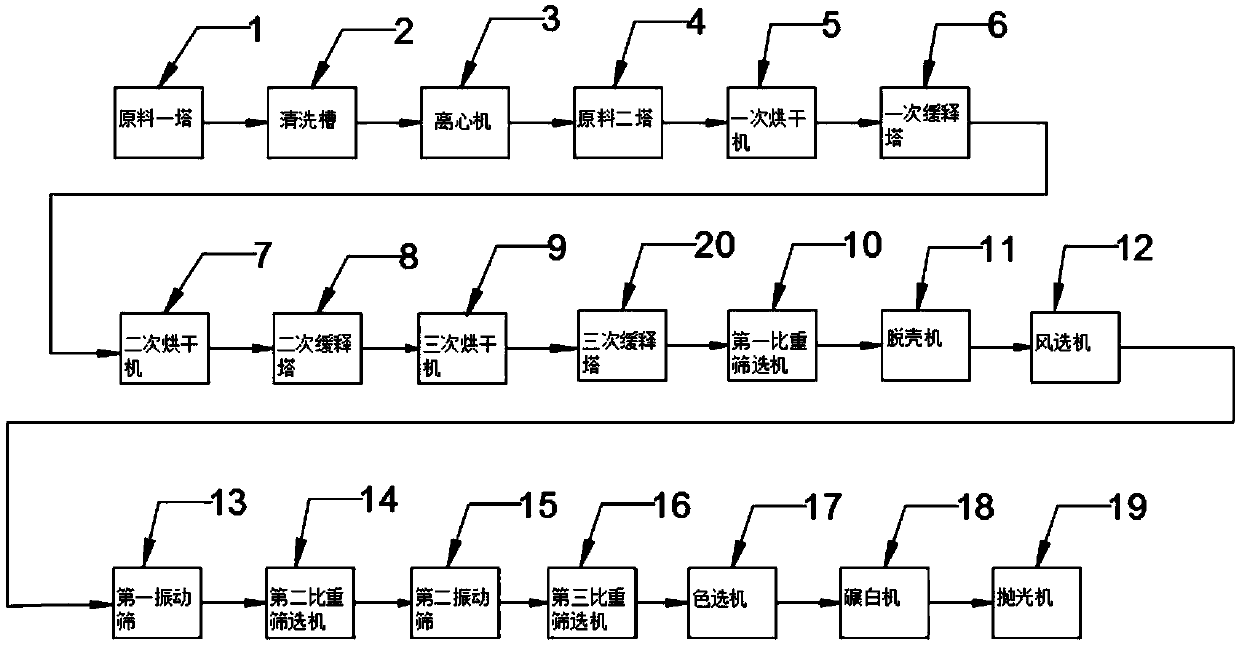

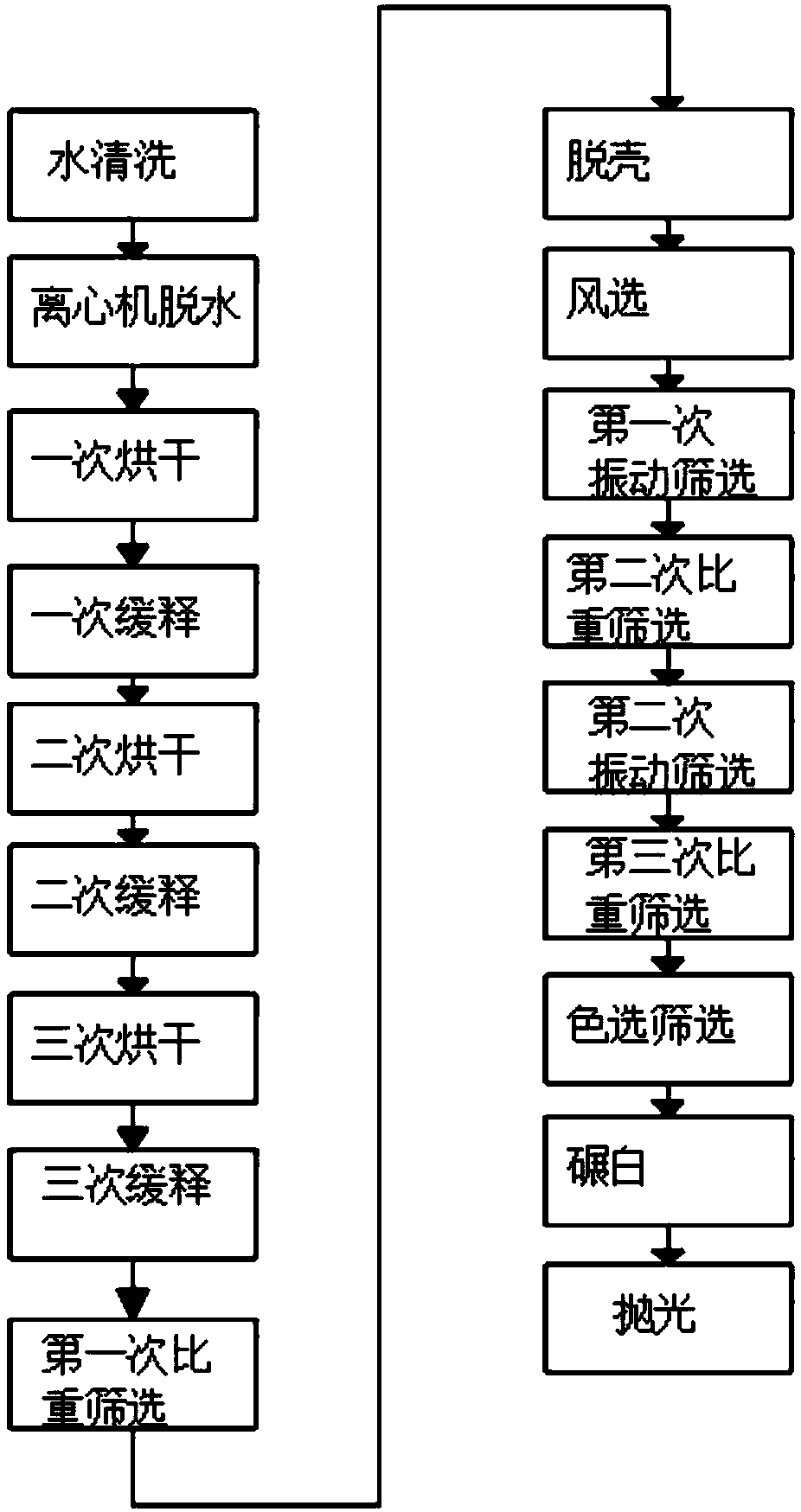

[0043] refer to figure 1 with Figure 4 ,

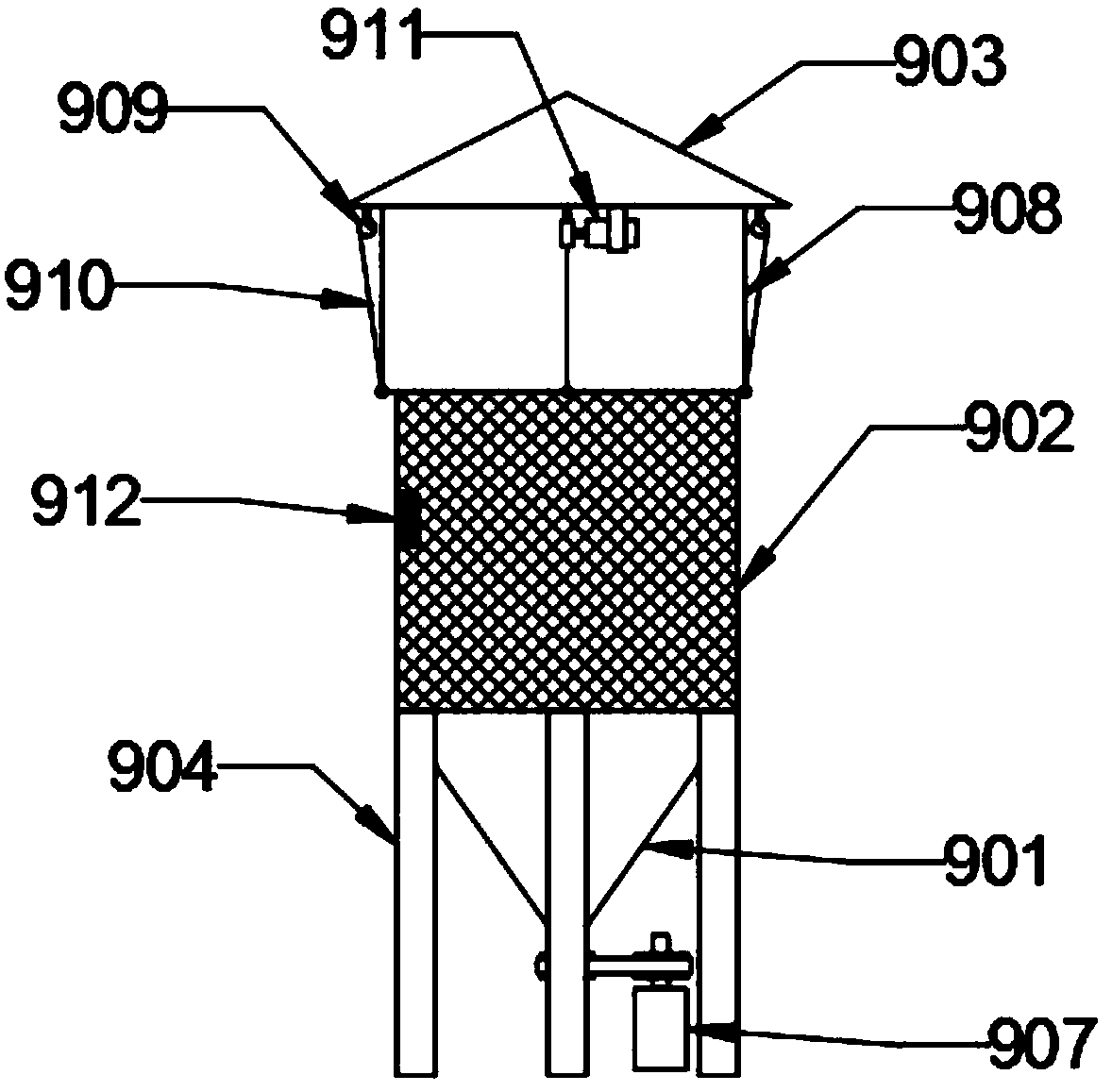

[0044]A barley rice processing production line, said barley rice processing production line is provided with a dryer 5, a slow-release tower 6, a second dryer 7, a second slow-release tower 8, a third dryer 9, a first Specific gravity screening machine 10, shelling machine 11, wind separator 12, first vibrating screen 13, second specific gravity screening machine 14, second vibrating screen 15, third specific gravity screening machine 16, color sorter 17, whitening machine 18 And the polishing machine 19, the discharge port of the primary dryer 5 is connected to the inlet of the primary slow-release tower 6 through the conveyor belt, the outlet of the primary slow-release tower 6 is connected to the inlet of the secondary dryer 7 through the conveyor belt, and the outlet of the secondary dryer 7 is connected through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com