Precast caisson mold assembly and using method thereof

A caisson and mold technology, applied in the direction of mold auxiliary parts, molds, manufacturing tools, etc., can solve the problems of waste of resources, heavy mold modification work, complex structure, etc., to achieve arbitrary adjustment, good molding effect, and good mold integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

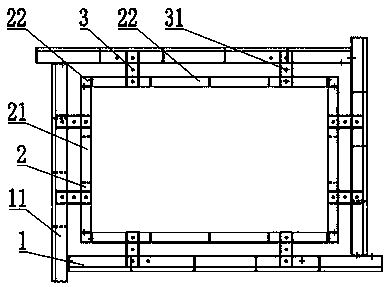

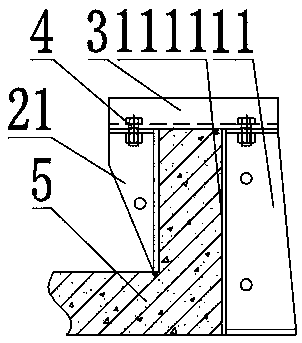

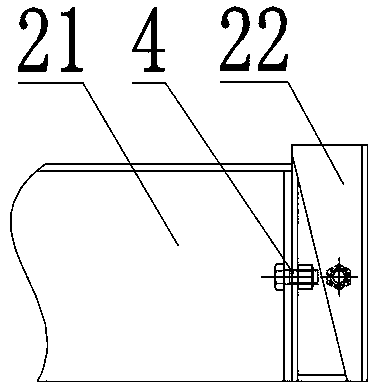

[0035] refer to Figure 1~6 : a kind of prefabricated caisson mold assembly of the present embodiment, comprises inner mold 2, outer mold 1 and cantilever 3; Described inner mold 2 is fixed in the outer mold 1 by cantilever 3; Described outer mold 1 is made of 4 pieces It is composed of two outer rib forms 11 that vertically abut against each other; the outer rib forms 11 have a rib surface 1111 for abutting against the caisson 5, and any one of the outer rib forms 11 in the outer forms 1 is opposite to the other. The position of the outer rib mold 11 is adjustable, so that the size of the cavity enclosed by the outer rib mold 11 and the inner mold 2 is adjustable.

[0036] The outer rib formwork 11 is detachably arranged on the workbench through bolts.

[0037] Described outer rib mold 11 comprises bottom plate 112, outer rib panel 111, outer rib top plate 113 and rib plate 114; connected, the ribs 114 are arranged on the outer baffle panel at intervals, and are located bet...

Embodiment 2

[0049] refer to Figure 7 with 8 : a kind of prefabricated caisson mold assembly of the present embodiment, compared with embodiment 1, there is following difference:

[0050] The outer rib formwork 11 is detachably arranged on the workbench through a magnetic fixing mechanism. Among them, the magnetic fixing mechanism can adopt the existing technology, such as the magnetic fixing mechanism in the following patent documents: publication (announcement) number: CN202753276U, publication (announcement) number: CN201511367U, publication (announcement) number: CN202828940U, publication (announcement) number: CN 202391119 U. When the magnetic control rod is pressed down, it is adsorbed on the top, and the 4 outer rib molds 11 are pressed and fixed on the top; when the magnetic control rod is pulled up, the upper position can be adjusted to facilitate changing the position of the outer rib molds 11 ; Preferably, screw holes are also provided on the outer rib mold 11, and the angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com