Integrated rotation seal system

A rotary sealing, one-piece technology, applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of high production and use costs, high replacement costs, blocking failures, etc., and achieve low maintenance costs. The effect of low maintenance and blockage avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

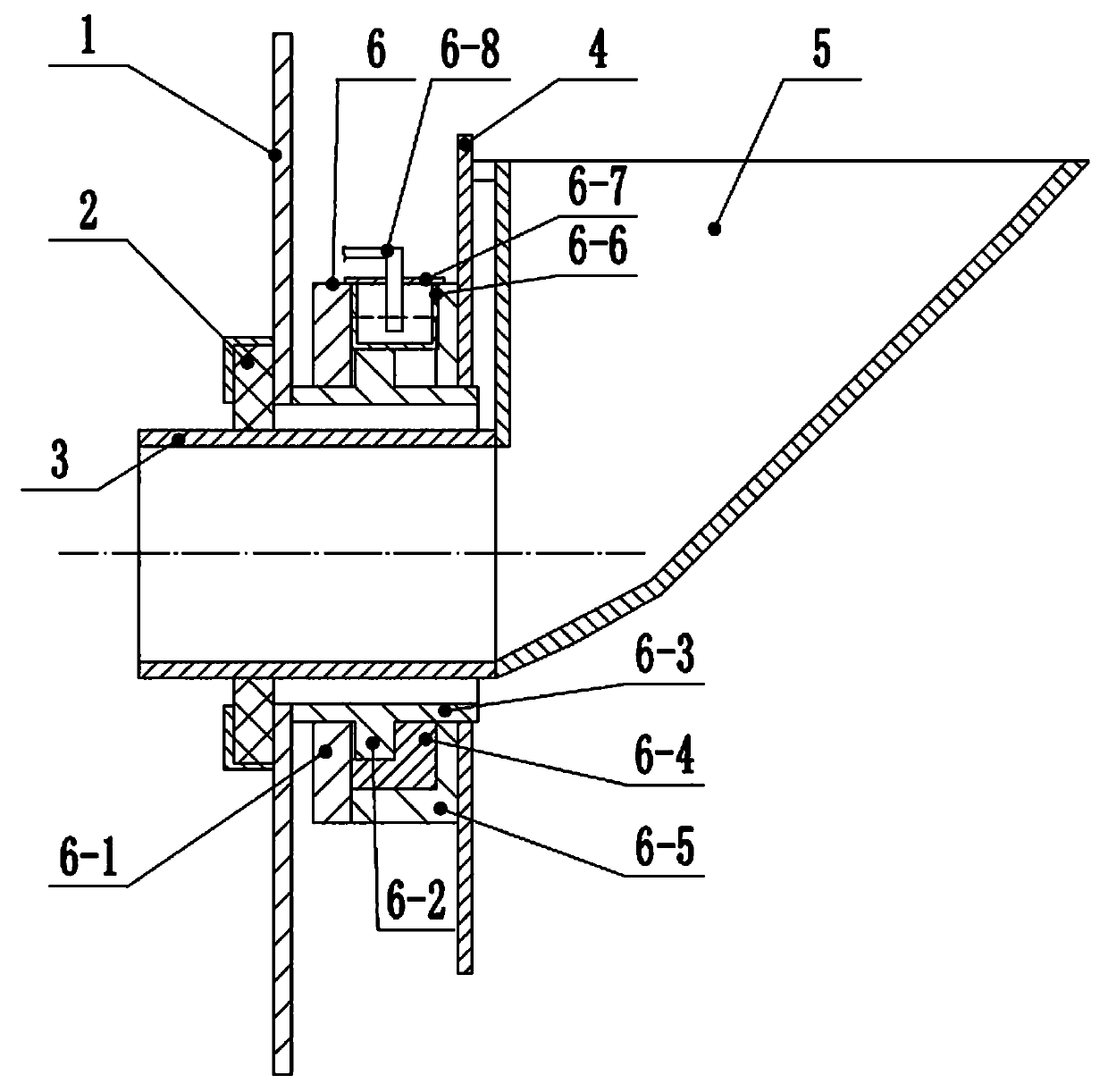

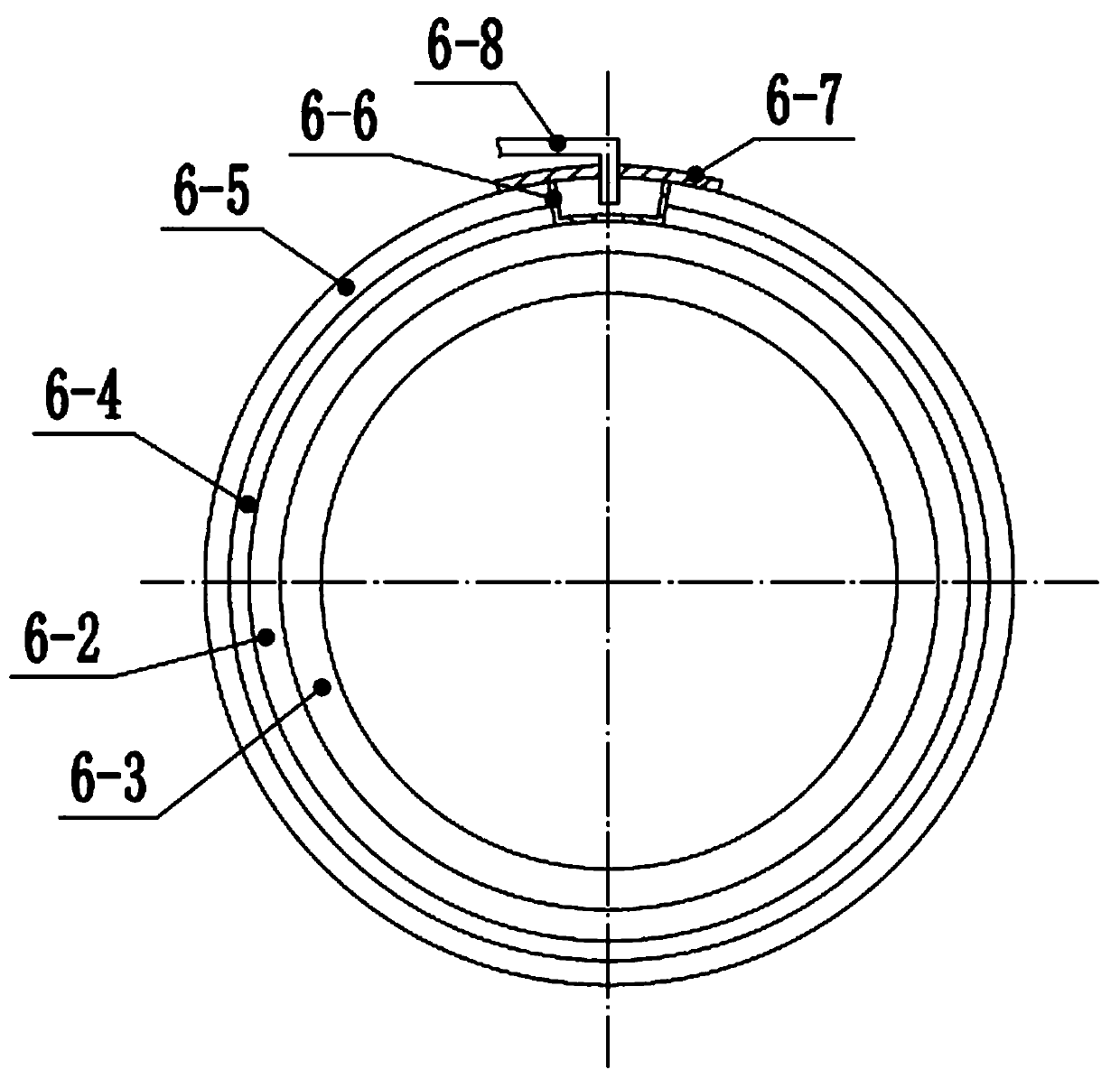

[0022] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0023] Such as figure 1 and 2 , an integrated rotary sealing system, used for the rotary sealing of the mixing drum of the mixer truck.

[0024] The mixer truck includes a car body and the mixing drum installed on the car body, and also includes a revolving cover 1, a central hole is provided on the revolving cover 1, and the outer circle of the revolving cover 1 is in contact with the mixing drum to follow the rotation of the mixing drum; it also includes a mobile frame 4 movably installed on the vehicle frame and a driving device for driving the mobile frame 4 to move relative to the vehicle body. A combined rotary support device 6 is also provided. The rotary cover 1 is installed on the mobile frame 4 through the combined rotary support device 6. On the one hand, it moves with the mobile frame 4, and on the other hand, it will rotate with the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com