Corrugated board score line cracking control method

A corrugated board and corrugated board technology, applied in the field of corrugated board size burst line control, can solve the problems of rising scrap rate, economic loss of enterprises, delayed delivery, etc., to improve the pass rate, maintain folding resistance, reduce effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

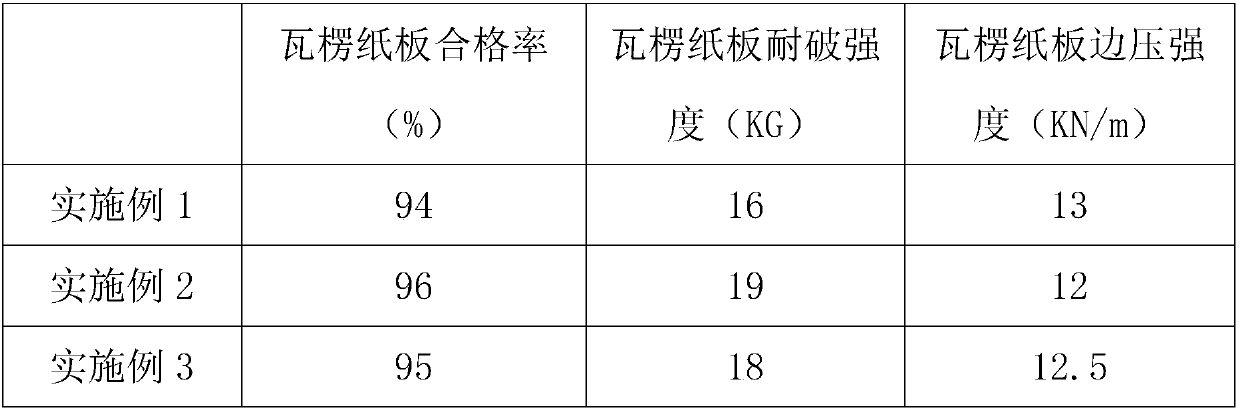

Embodiment 1

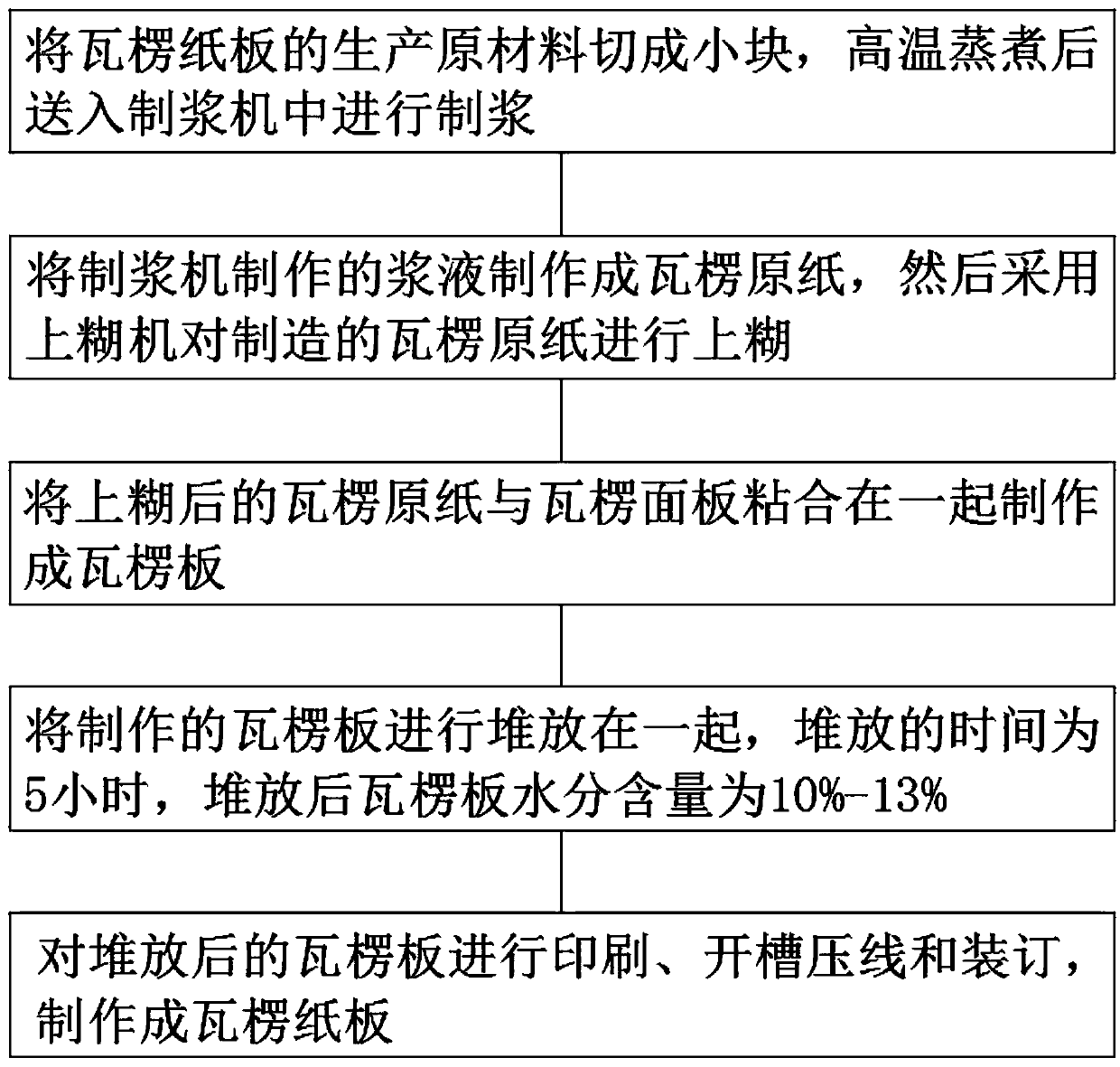

[0023] (1) Cut the raw materials of corrugated cardboard into small pieces, cook them at high temperature and send them to the pulping machine for pulping. During the pulping process of the pulping machine, the ratio of starch to water is 1:3.5. to stir;

[0024] (2), the slurry that pulping machine is made is made into corrugated base paper, then adopts pasting machine to carry out pasting to the manufactured corrugated base paper, and the amount of pasting when adopting pasting machine to manufacture corrugated base paper is 10g / ㎡;

[0025] (3) Glue the corrugated base paper and corrugated panels together to make corrugated boards. During the production of corrugated boards, double-sided machines are used for heating. When heating, the preheating wheels are used to preheat first, and the preheating wheels are reduced. The contact area is then heat-treated by a hot plate. The steam pressure during the heat treatment of the hot plate is 1.0MPa, the temperature of the hot pla...

Embodiment 2

[0031] (1) Cut the raw materials of corrugated cardboard into small pieces, cook them at high temperature and send them to the pulping machine for pulping. During the pulping process of the pulping machine, the ratio of starch to water is 1:3.5. to stir;

[0032] (2), the slurry that pulping machine is made is made into corrugated base paper, then adopts pasting machine to carry out pasting to the manufactured corrugated base paper, and the amount of pasting when adopting pasting machine to manufacture corrugated base paper is 10g / ㎡;

[0033] (3) Glue the corrugated base paper and corrugated panels together to make corrugated boards. During the production of corrugated boards, double-sided machines are used for heating. When heating, the preheating wheels are used to preheat first, and the preheating wheels are reduced. The contact area is then heat-treated by a hot plate. The steam pressure during the heat treatment of the hot plate is 1.0MPa, the temperature of the hot pla...

Embodiment 3

[0039] (1) Cut the raw materials of corrugated cardboard into small pieces, cook them at high temperature and send them to the pulping machine for pulping. During the pulping process of the pulping machine, the ratio of starch to water is 1:3.5. to stir;

[0040] (2), the slurry that pulping machine is made is made into corrugated base paper, then adopts pasting machine to carry out pasting to the manufactured corrugated base paper, and the amount of pasting when adopting pasting machine to manufacture corrugated base paper is 10g / ㎡;

[0041] (3) Glue the corrugated base paper and corrugated panels together to make corrugated boards. During the production of corrugated boards, double-sided machines are used for heating. When heating, the preheating wheels are used to preheat first, and the preheating wheels are reduced. The contact area is then heat-treated by a hot plate. The steam pressure during the heat treatment is 1.2MPa, the temperature of the hot plate is 165°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com