Vacuum non-destructive solid-liquid mixing filling equipment

A technology of solid-liquid mixing and filling equipment, which is applied in the field of filling devices for solid-liquid mixtures and non-destructive automatic filling devices for perfusion devices, which can solve the problems of large filling errors, slow filling speed, and high production costs. , to achieve the effects of small material error, accurate material transfer volume and high safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

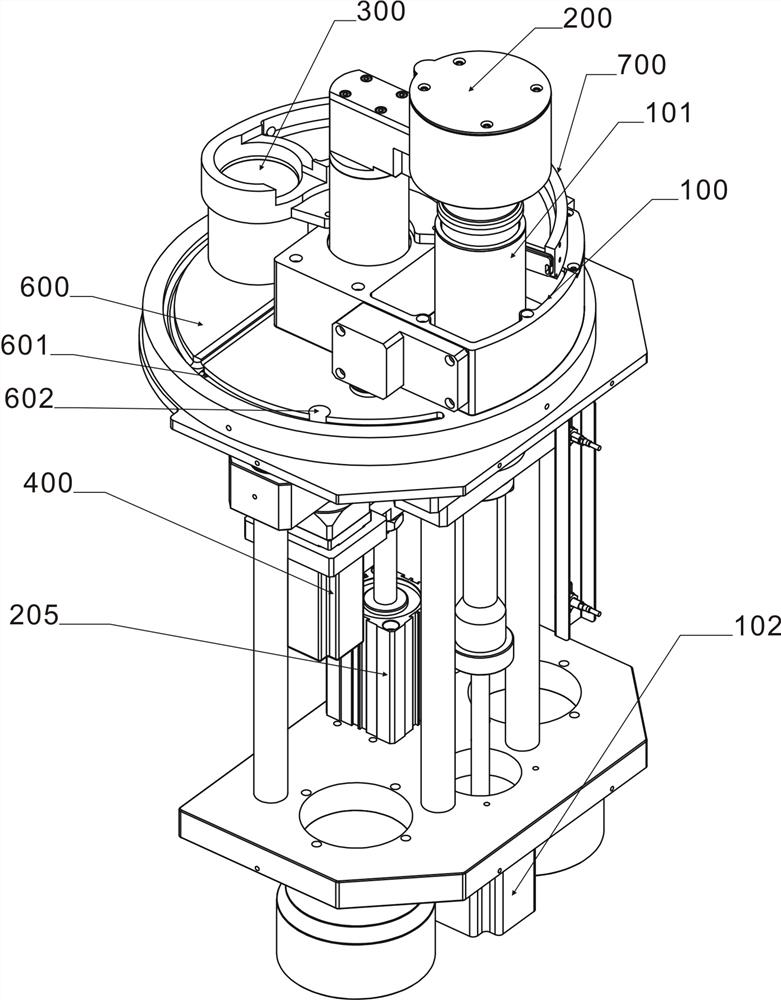

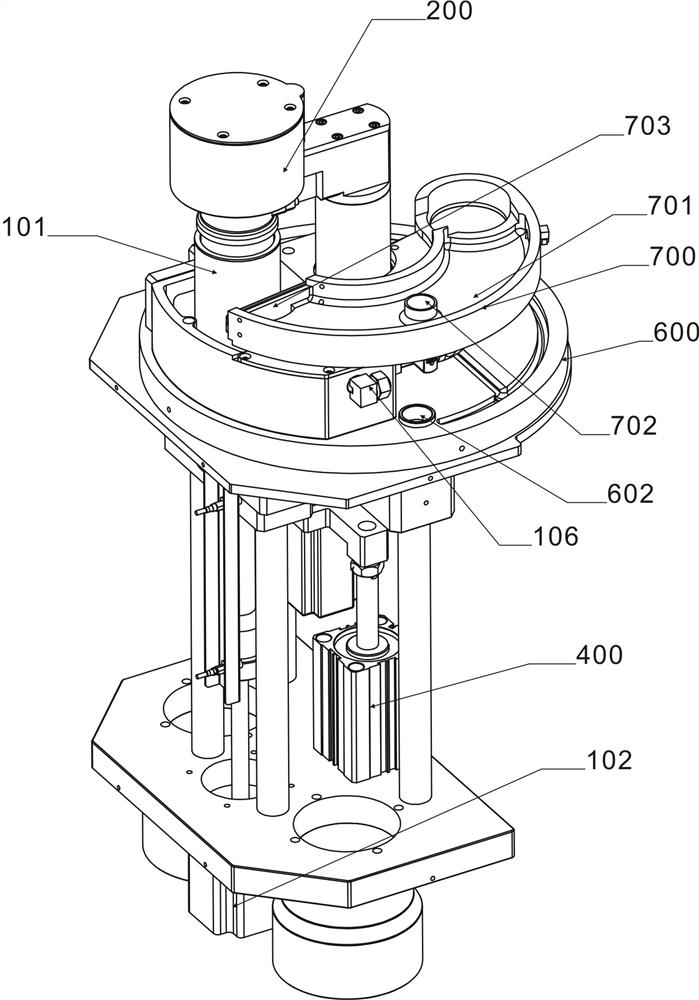

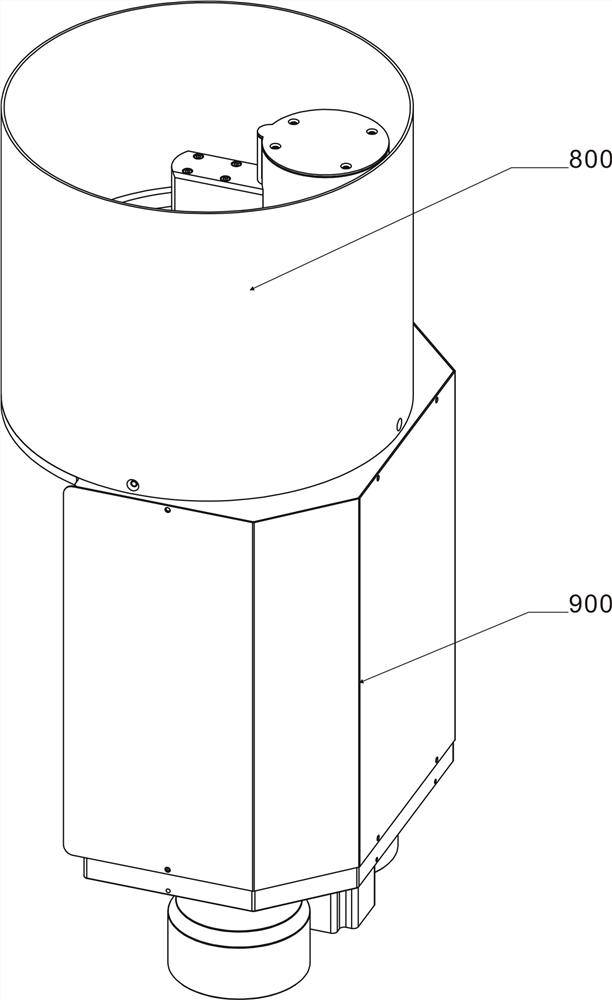

[0048] Such as Figure 1-10 As shown, a vacuum non-destructive solid-liquid mixing filling equipment includes a storage tank 100, a material transfer mechanism 200, a discharge funnel 300, and a first power device 400, wherein the first power device 400 uses a motor. The first power device 400 is connected to the material transfer mechanism 200 and controls the material transfer mechanism 200 to reciprocate between the storage tank 100 and the discharge funnel 300 to realize the transfer of materials. The material transfer mechanism 200 includes a material transfer chamber 201 and a vacuum pipeline 202 communicating with the material transfer chamber 201. The vacuum pipeline 202 is externally connected to a vacuum pump. After the material cavity 201 is aligned with the discharge trough 100 to absorb enough materials, the first power device 400 controls the material shifting mechanism 200 to rotate to the top of the discharge funnel 300, and then turns off the vacuum pump, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com