A mobile garbage compression equipment with electromechanical and hydraulic integration

A garbage compression and mobile technology, which is applied in the direction of garbage collection, garbage transmission, loading/unloading, etc., can solve the problems of high force requirements for structural parts, high operating costs, and unsatisfactory performance, so as to improve environmental protection and work efficiency. Reduce floor space and improve extrusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

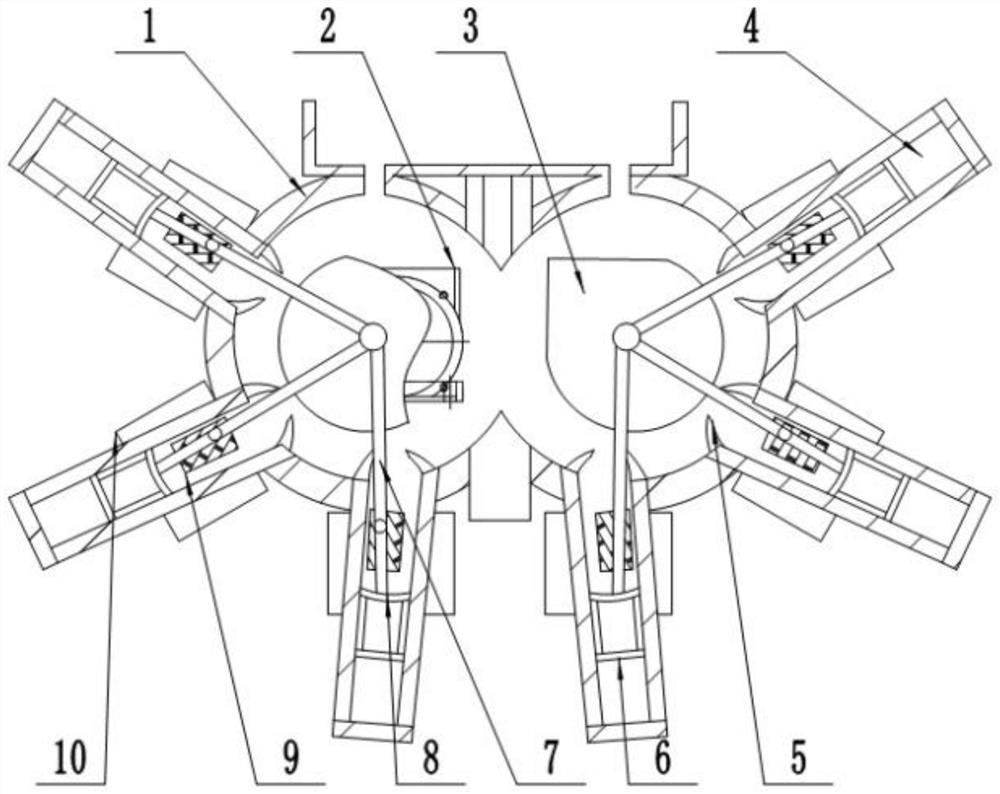

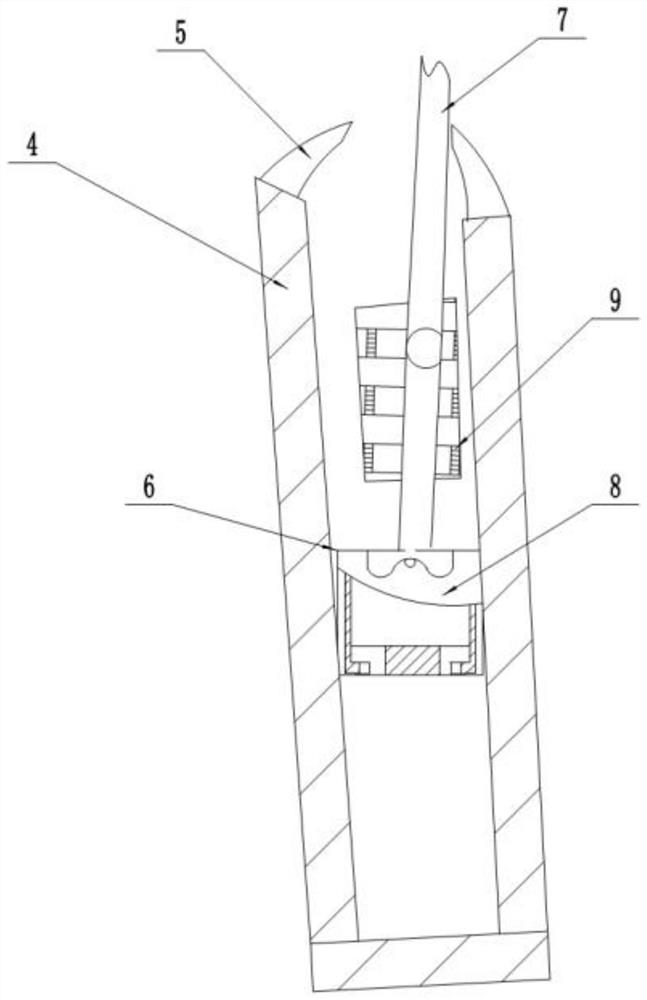

[0024] The reference signs in the drawings of the specification include: compression box 1, drive motor 2, rotor 3, waste liquid treatment channel 4, lug 5, piston 6, connecting rod group 7, groove 8, discharge port 9, water storage tank 10.

[0025] The embodiment is basically as attached figure 1 Shown: a mobile garbage compression equipment with electromechanical and hydraulic integration, including a compression box 1 and a drive motor 2, two mutually symmetrical elliptical rotors 3 are installed in the compression box 1, and the rotor 3 is driven by the drive motor 2, A group of waste liquid treatment channels 4 symmetrically arranged along the central axis of the compression box 1 is formed on the circumference of the rotor 3. The waste liquid treatment channels 4 are radially arranged, and the number of waste liquid treatment channels 4 is 6. The waste liquid treatment channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com