Shock wave focus excitation device loading high temperature environment and working method thereof

A shock wave focusing and excitation device technology, which is applied in the direction of microstructure devices, optical waveguide coupling, TV system components, etc., can solve problems such as uneven temperature field distribution and reduced accuracy, and achieve improved reliability and stability performance, improve accuracy, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

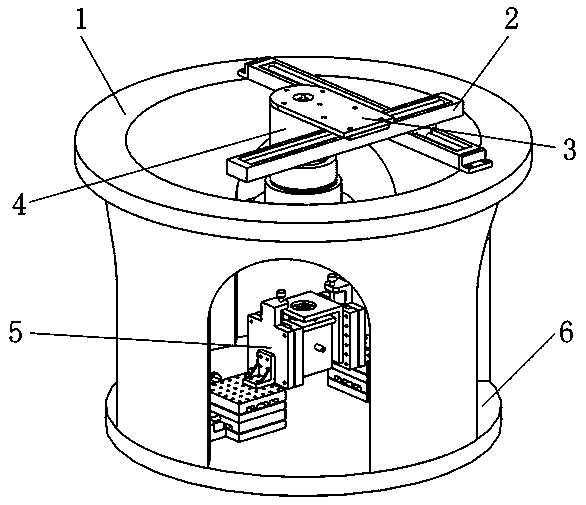

[0028] Figure 1-10 A structural diagram of a shock focusing excitation device loaded with a high temperature environment is shown.

[0029] figure 1 Among them, the shock wave focusing excitation device loaded in a high-temperature environment includes a cylinder body 1, a motorized two-axis translation stage 2, a mounting plate 3, an optical heating unit 4, and a microstructure excitation unit 5. The bottom plate 6 of the cylinder 1 is provided with a microstructure excitation unit 5 , and the top of the cylinder 1 is provided with an electric two-axis translation platform 2 , and an optical heating unit 4 is installed on the slider of the electric two-axis translation platform 2 through a mounting plate 3 .

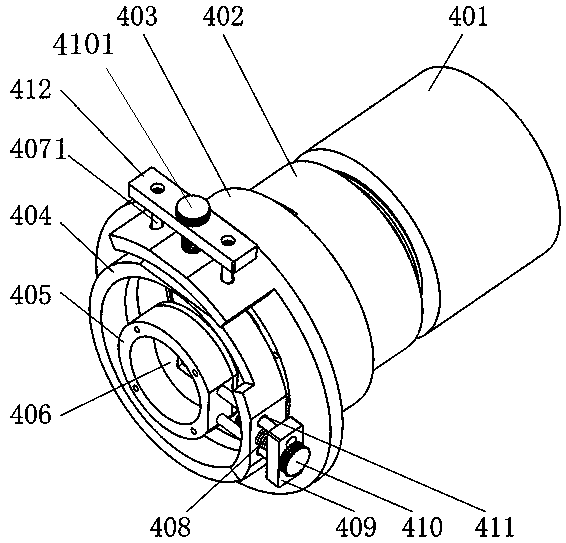

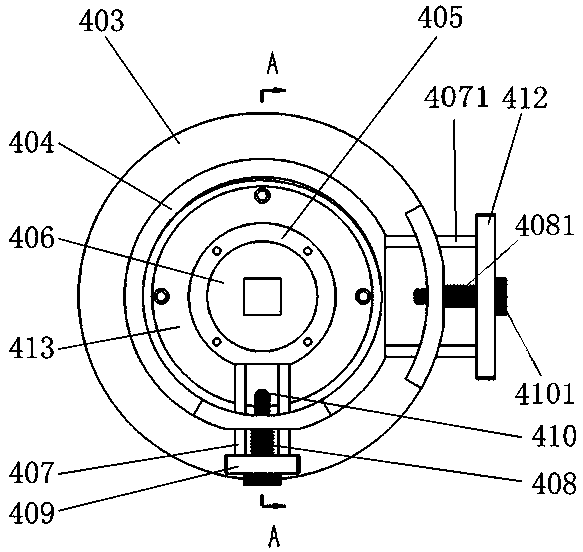

[0030] figure 2 , 3 Among them, the optical heating unit 4 includes a front sleeve 403 , a connecting sleeve 402 and a rear sleeve 401 which are screwed in sequence, and a parallel light source 415 is arranged in the central hole at the tail of the rear sleeve 401 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com