Fenton oxidation effluent post-treatment method

A technology of Fenton oxidation and treatment steps, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of inability to ensure that the sewage will no longer be reversed, and the inability to completely remove iron ions in the sewage system, etc. problem, to achieve the effect of low cost, less drug dosage, and elimination of anti-color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

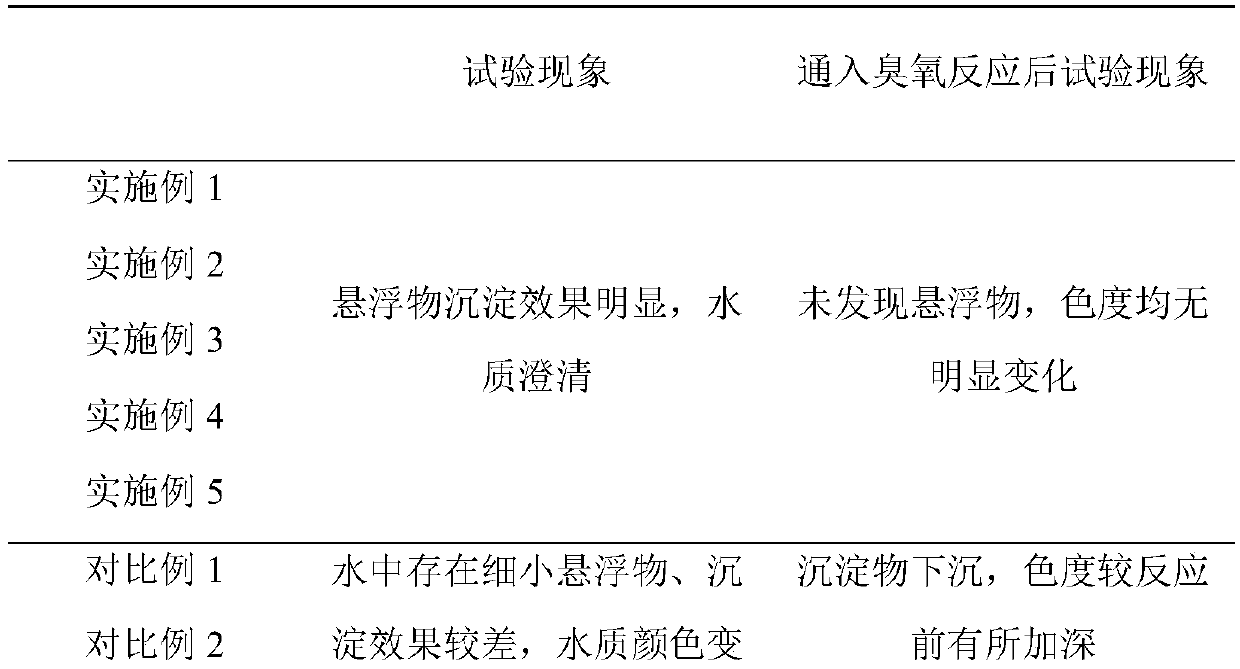

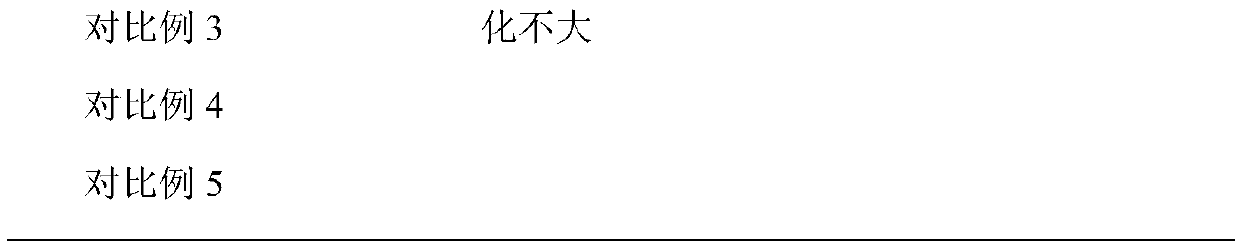

Embodiment 1

[0038] Provide 1L of mud-water mixture after Fenton oxidation reaction, wherein the pH of the mud-water mixture is 6.54; carry out aeration treatment on the mud-water mixture so that the dissolved oxygen concentration of the mixture is ≥5mg / L, and the aeration time is 10 minutes , and then add slaked lime to adjust the mud-water mixture, mix and react for 5 minutes, and adjust to pH 9.0; then add 1% (1 mL) flocculant PAM and mix evenly, and settle for 20 minutes to obtain a treatment solution.

Embodiment 2

[0040] Provide 1L of mud-water mixture after Fenton oxidation reaction, wherein the pH of the mud-water mixture is 6.54; carry out aeration treatment on the mud-water mixture so that the dissolved oxygen concentration of the mixture is 5 mg / L, and the aeration time is 15 minutes , and then add slaked lime to adjust the mud-water mixture, mix and react for 5 minutes, and adjust to pH 9.0; then add 1% (1 mL) flocculant PAM and mix evenly, and settle for 25 minutes to obtain a treatment solution.

Embodiment 3

[0042] Provide 1L of mud-water mixture after Fenton oxidation reaction, wherein the pH of the mud-water mixture is 6.54; carry out aeration treatment on the mud-water mixture so that the dissolved oxygen concentration of the mixture is 5 mg / L, and the aeration time is 20 minutes , and then add slaked lime to adjust the mud-water mixture, mix and react for 5 minutes, and adjust to pH 9.0; then add 1% (1 mL) flocculant PAM and mix evenly, and settle for 20 minutes to obtain a treatment solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com