Composite rust inhibitor for steel bars based on long-chain biological nucleic acid and its preparation method and application

A steel bar rust inhibitor and composite technology, applied in anti-corrosion coatings and other directions, can solve the problems of large amount of rust inhibitor, complex synthesis method and high synthesis cost, and achieve the effects of good environmental protection, simple synthesis method and long action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

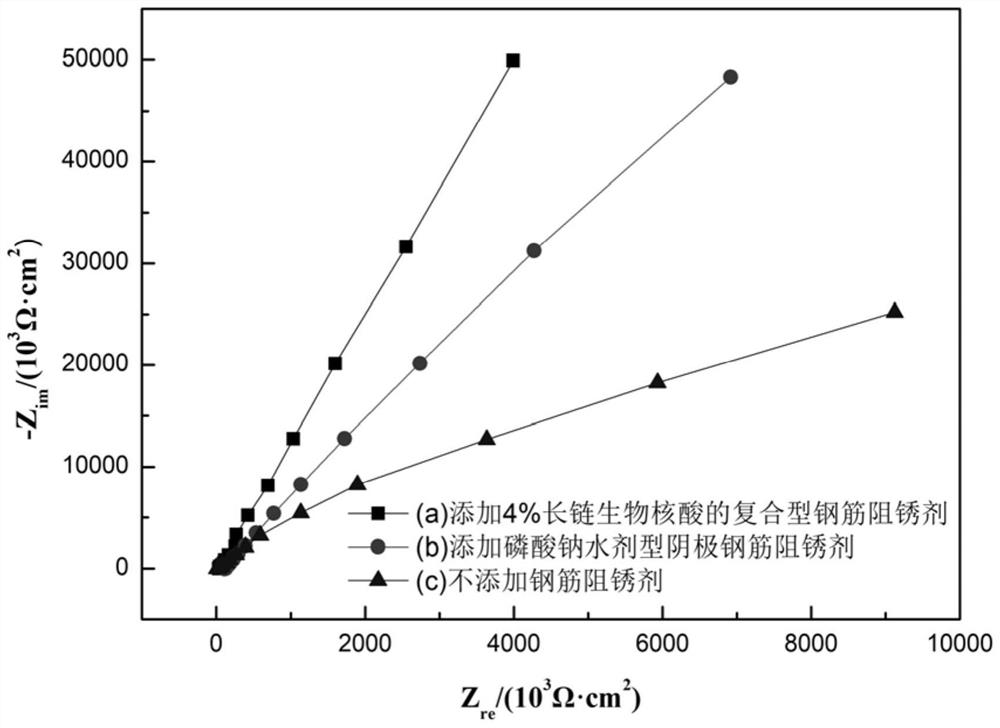

Embodiment 1

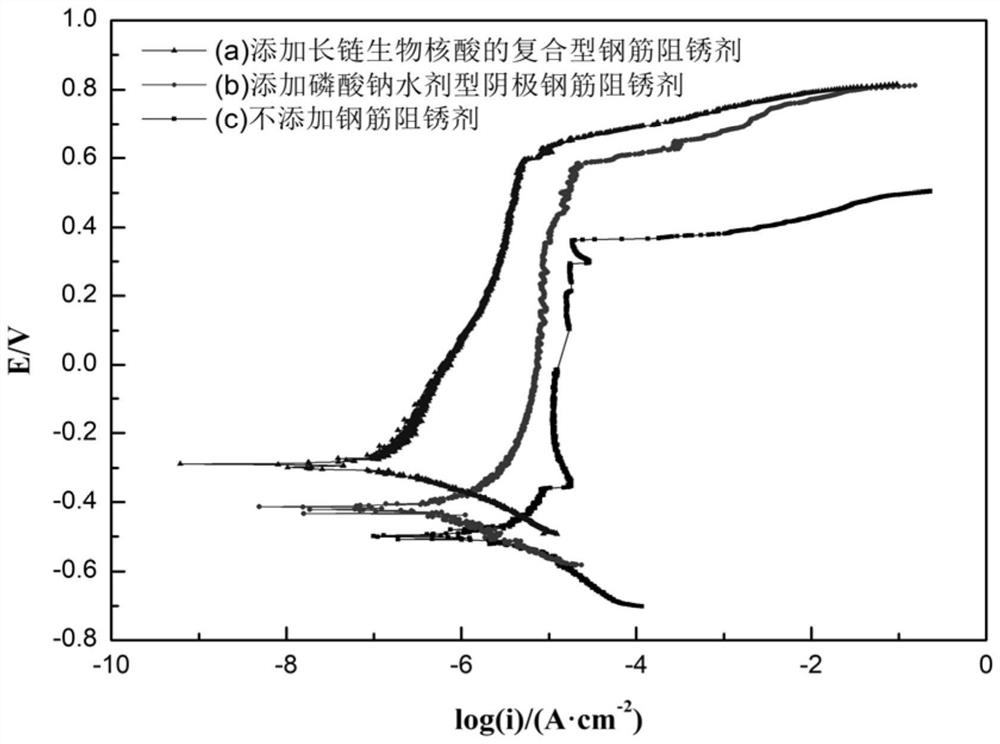

[0035] The compound rust inhibitor for steel bars based on long-chain biological nucleic acid in this embodiment is composed of the following components in mass percentage: 96% of sodium phosphate water-based cathodic rust inhibitor for steel bars, and 4% of long-chain biological nucleic acid rust inhibitor. The composite rust inhibitor for steel bars is prepared by the following method: weighing each component according to the mass percentage, mixing and stirring evenly to obtain the finished product.

[0036] According to the above technical scheme, a steel bar section with a diameter of φ10mm and a length of 2cm is selected as the working electrode. Before the experiment, use 200#, 600#, 1000# and 1200# metallographic sandpaper to polish the steel bars step by step. One end of the steel bar section is used as the working surface, and the other end is connected with a copper wire, and then the side surface is wrapped with epoxy resin, and then the working surface is polished...

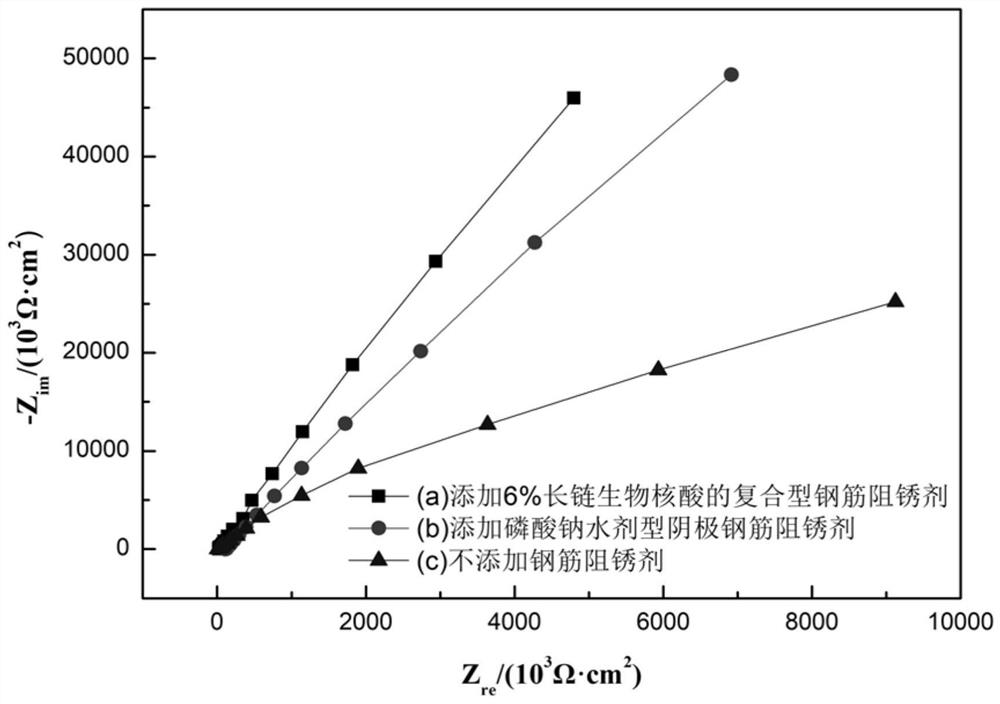

Embodiment 2

[0041] The composite steel bar rust inhibitor based on long-chain biological nucleic acid of this embodiment is composed of the following components in mass percentage: 94% of sodium phosphate aqueous cathodic steel bar rust inhibitor, and 6% of long-chain biological nucleic acid rust inhibitor. The composite rust inhibitor for steel bars is prepared by the following method: weighing each component according to the mass percentage, mixing and stirring evenly to obtain the finished product.

[0042] According to the above technical scheme, a steel bar section with a diameter of φ10mm and a length of 2cm is selected as the working electrode. Before the experiment, use 200#, 600#, 1000# and 1200# metallographic sandpaper to polish the steel bars step by step. One end of the steel bar section is used as the working surface, and the other end is connected with a copper wire, and then the side surface is wrapped with epoxy resin, and then the working surface is polished into a mirro...

Embodiment 3

[0046] The compound steel rust inhibitor based on long-chain biological nucleic acid of this embodiment is composed of the following components in mass percentage: 92% of sodium phosphate aqueous cathodic steel rust inhibitor, and 8% of long-chain biological nucleic acid rust inhibitor. The composite rust inhibitor for steel bars is prepared by the following method: weighing each component according to the mass percentage, mixing and stirring evenly to obtain the finished product.

[0047] According to the above technical scheme, a steel bar section with a diameter of φ10mm and a length of 2cm is selected as the working electrode. Before the experiment, use 200#, 600#, 1000# and 1200# metallographic sandpaper to polish the steel bars step by step. One end of the steel bar section is used as the working surface, and the other end is connected with a copper wire, and then the side surface is wrapped with epoxy resin, and then the working surface is polished into a mirror surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com