Gypsum-based hydraulic hard grouting material and preparation method and application thereof

A technology of grouting materials and gypsum, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of high cost of polymer materials, inconformity with the concept of low-carbon environmental protection development, and obstacles to widespread application, so as to reduce the amount of cement And the effect of slag, improving mechanical properties and softening coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

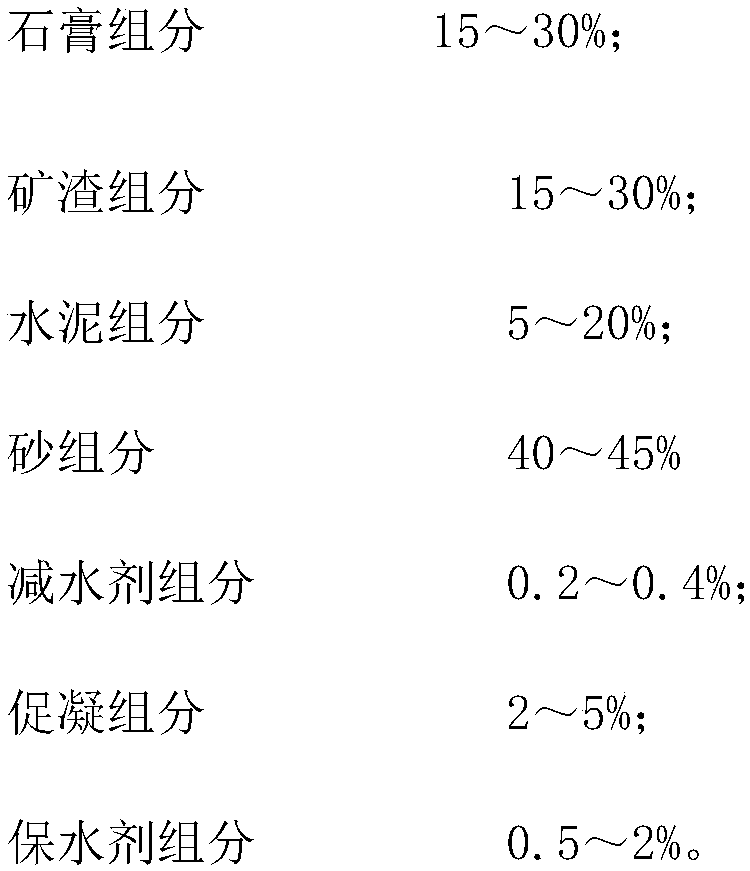

[0026] Gypsum-based hydraulic grouting material, the weight percentage of each component is as follows:

[0027] Phosphogypsum dihydrate 30%;

[0028] S105 slag 15%;

[0029] PO525 cement 5%;

[0030] Sand 42.7%;

[0031] Water reducer 0.3%;

[0032] Coagulant component 5%;

[0033] Water retaining agent 2%.

[0034] The preparation steps of the gypsum-based hydraulic grouting material are as follows: Step 1: Weigh the required phosphogypsum dihydrate, slag, cement, sand, water reducing agent, coagulation-accelerating components and water-retaining components according to the weight percentage of each component described Mix well in a mixer to form a solid grouting material and pack it into bags; Step 2: Transport the solid grouting material obtained in step 1 to the construction site, take the solid material according to the actual demand, add water and stir evenly according to the water-solid ratio of 0.14 ; Step 3: Stir the mixture obtained in step 2 for 3-10 minutes ...

Embodiment 2

[0036] Gypsum-based hydraulic grouting material, the weight percentage of each component is as follows:

[0037] Phosphogypsum dihydrate 23.5%;

[0038] S105 slag 15%;

[0039] PO525 cement 12.5%;

[0040] Sand 44.8%;

[0041] Water reducer 0.2%;

[0042] Coagulant component 3%;

[0043] Water retaining agent 1%.

[0044] The preparation steps of the gypsum-based hydraulic grouting material are as follows: Step 1: Weigh the required phosphogypsum dihydrate, slag, cement, sand, water reducing agent, coagulation-accelerating components and water-retaining components according to the weight percentage of each component described Mix well in a mixer to form a solid grouting material and pack it into bags; Step 2: Transport the solid grouting material obtained in step 1 to the construction site, take the solid material according to the actual demand, add water and stir evenly according to the water-solid ratio of 0.14 ; Step 3: Stir the mixture obtained in step 2 for 3-10 min...

Embodiment 3

[0046] Gypsum-based hydraulic grouting material, the weight percentage of each component is as follows:

[0047] Phosphogypsum dihydrate 15%;

[0048] S115 slag 30%;

[0049] PO325 cement 5%;

[0050] Sand 45%;

[0051] Water reducing agent 0.3%;

[0052] Coagulant component 3.8%;

[0053] Water retaining agent 0.9%.

[0054]The preparation steps of the gypsum-based hydraulic grouting material are as follows: Step 1: Weigh the required phosphogypsum dihydrate, slag, cement, sand, water reducing agent, coagulation-accelerating components and water-retaining components according to the weight percentage of each component described Mix well in a mixer to form a solid grouting material and pack it into bags; Step 2: Transport the solid grouting material obtained in step 1 to the construction site, take the solid material according to the actual demand, add water and stir evenly according to the water-solid ratio of 0.14 ; Step 3: Stir the mixture obtained in step 2 for 3-10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com