Method for preparing calcium fluoride transparent ceramic by vacuum hot pressing sintering with lithium fluoride as auxiliary

A technology of vacuum hot pressing sintering and transparent ceramics, applied in the field of preparation of fluoride transparent ceramics, can solve the problems of opacity and low sintering activity of calcium fluoride ceramics, achieve good transparency and promote the effect of densification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

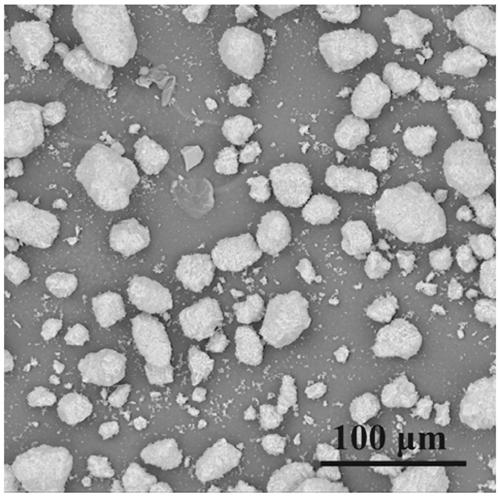

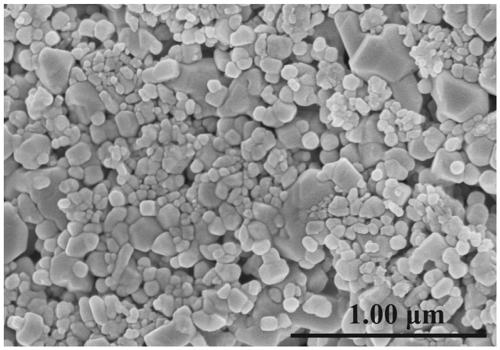

[0024] 1) Preparation of powder raw materials: Weigh 5g of commercially available calcium fluoride powder, add lithium fluoride powder to make the content of lithium fluoride 2.0wt%, add absolute ethanol to submerge the powder, and place in Ultrasonic treatment in an ultrasonic cleaner for 60 minutes, then fully mixed, and dried in an oven for later use;

[0025] 2) Sample loading: Weigh 2 g of the mixed powder obtained in step 1), put it into a graphite mold with an inner diameter of 16 mm, and separate the mold from the mixed powder with graphite paper;

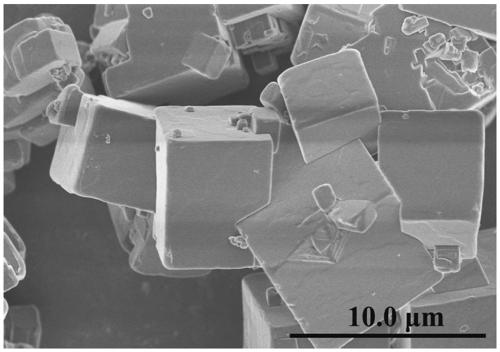

[0026] 3) Sintering of transparent ceramics: put the filled graphite mold into a vacuum hot-press furnace, evacuate to better than 10Pa, heat up to 800°C, then apply a pressure of 30MPa, and keep warm for 3h;

[0027] 4) Treatment of transparent ceramics: After sintering, take out the ceramic samples, firstly grind them roughly with sandpaper, and then polish the samples with a polishing machine to obtain calcium fluoride t...

Embodiment 2

[0030] 1) Preparation of powder raw materials: Weigh 5g of commercially available calcium fluoride powder, add lithium fluoride powder to make the content of lithium fluoride 2.0wt%, add absolute ethanol to submerge the powder, and place in Ultrasonic treatment in an ultrasonic cleaner for 60 min, then fully mixed, and dried in an oven for later use;

[0031] 2) Sample loading: Weigh 2 g of the mixed powder obtained in step 1), put it into a graphite mold with an inner diameter of 16 mm, and separate the mold from the mixed powder with graphite paper;

[0032] 3) Sintering of transparent ceramics: Put the filled graphite mold into a vacuum hot-press furnace, evacuate to better than 10Pa, heat up to 700°C, then apply a pressure of 30MPa, and keep warm for 3h;

[0033] 4) Treatment of transparent ceramics: After sintering, take out the ceramic samples, first rough grind them with sandpaper, and then polish the samples with a polishing machine to obtain calcium fluoride transpare...

Embodiment 3

[0035] 1) Preparation of powder raw materials: Weigh 5g of commercially available calcium fluoride powder, add lithium fluoride powder to make the content of lithium fluoride 2.0wt%, add absolute ethanol to submerge the powder, and place in Ultrasonic treatment in an ultrasonic cleaner for 20 minutes, then fully mixed, and dried in an oven for later use;

[0036] 2) Sample loading: Weigh 2 g of the mixed powder obtained in step 1), put it into a graphite mold with an inner diameter of 16 mm, and separate the mold from the mixed powder with graphite paper;

[0037] 3) Sintering of transparent ceramics: Put the filled graphite mold into a vacuum hot-press furnace, evacuate to better than 10Pa, heat up to 730°C, then apply a pressure of 50MPa, and keep warm for 3h;

[0038] 4) Treatment of transparent ceramics: after sintering, take out the ceramic samples, first rough grind them with sandpaper, and then polish the samples with a polishing machine to obtain calcium fluoride trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com