Supersonic-speed low-temperature separating device and crude oil stabilizing and light hydrocarbon recovering method and device

A separation device and light hydrocarbon recovery technology, which is applied in the recovery of liquid hydrocarbon mixtures and the petroleum industry, can solve the problems of long process, high equipment and operation costs, high investment and operation costs, etc. Small size, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

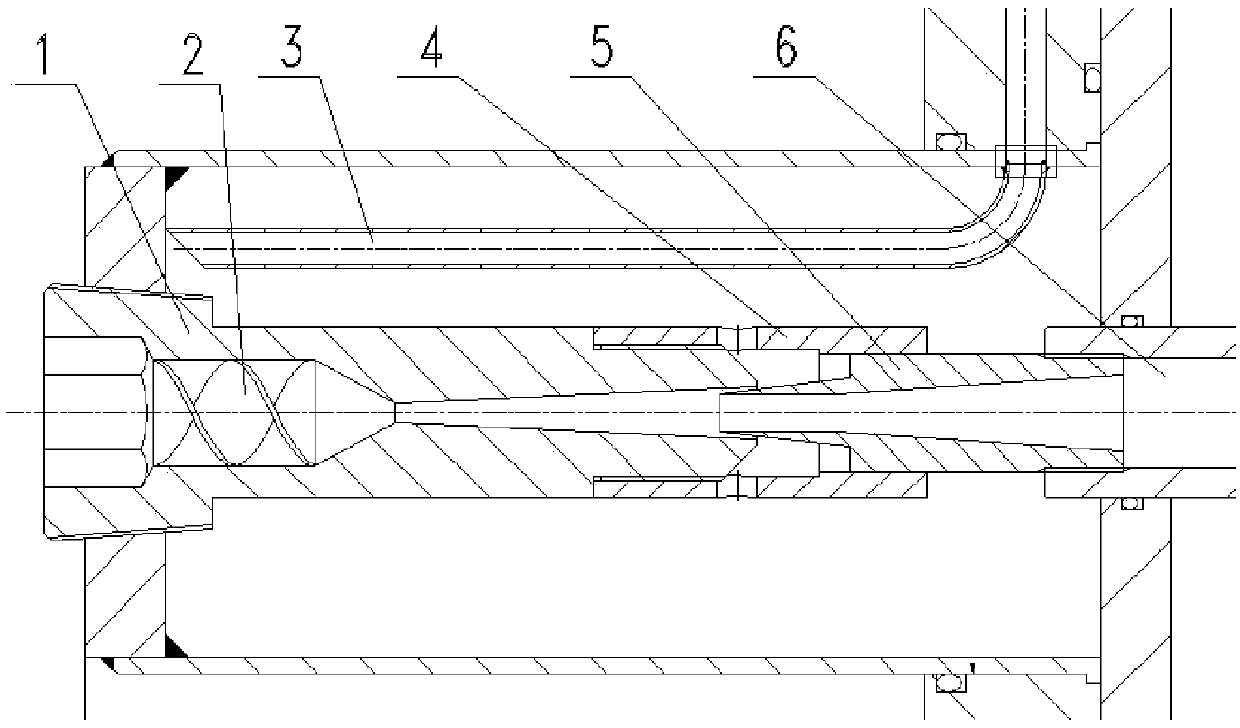

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

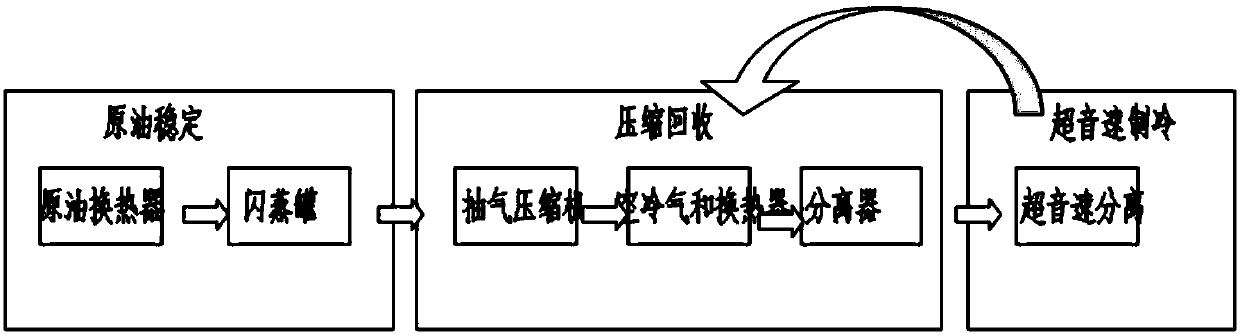

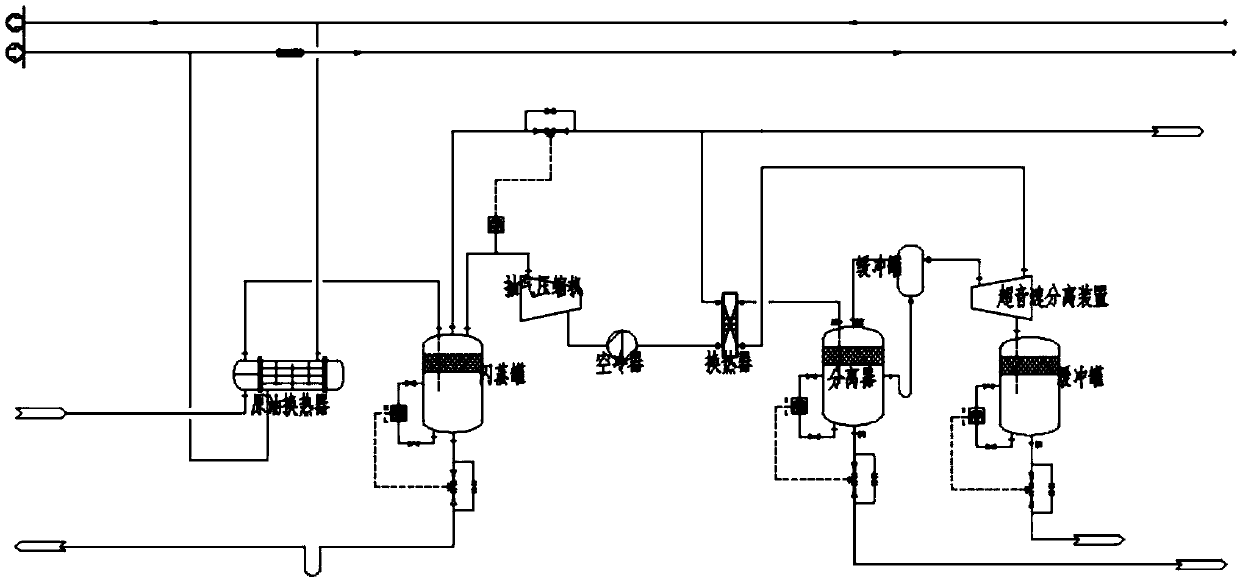

[0034] The stabilization of the crude oil refers to volatilization of the light components in the crude oil by means of decompression and heating, and the recovery of the light hydrocarbons condenses the flash steam by pressurizing and lowering the temperature of the flash steam. Expansion refrigeration obtains cooling capacity and cools the flash gas. The invention starts from the oil filling pipeline of the crude oil storage tank, stabilizes the crude oil through the heating and flashing process, recovers light hydrocarbons through the compression and expansion process, and combines the high-efficiency automatic control scheme to ensure the stable and safe operation of the system.

[0035] In view of the above analysis, a crude oil stabilization and light hydrocarbon recovery method can be summarized as the following steps:

[0036] (1) Volatilize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com