Method for Improving the Pitting Corrosion Resistance of G3 Alloy Plates Using the Preferential Distribution of Close-Packed Crystal Planes

A technology of alloy plate and crystal surface, which is applied in the field of metal corrosion protection, can solve the problems of G3 alloy parts that cannot meet the requirements of strength, environmental pollution, etc., and achieve the effect of facilitating rolling deformation, reducing environmental hazards, and ensuring toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

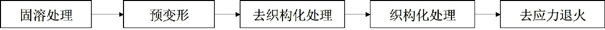

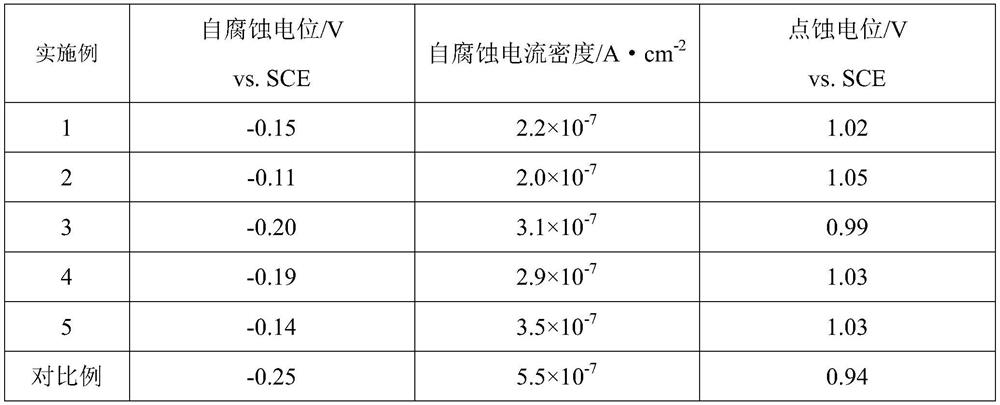

[0026] like figure 1 As shown, the steps of the method for improving the pitting corrosion resistance of the G3 alloy plate by using the preferred distribution of close-packed crystal planes in this embodiment are as follows:

[0027] (1) The G3 alloy plate is subjected to solution treatment, the solution temperature is 1070°C±5°C, the holding time is 30min, and the water is cooled to room temperature after the holding.

[0028] (2) Carry out pre-deformation treatment to the G3 alloy plate after solution treatment, the pre-deformation method is cold rolling, and the rolling amount is 30%;

[0029] (3) Detexturize the pre-deformed plate at a temperature of 1100°C ± 5°C, hold for 10 minutes, and cool to room temperature with water after the hold.

[0030] (4) Texturing the de-textured G3 alloy plate by cold rolling with a rolling weight of 50%.

[0031] (5) Stress-relief annealing was performed on the textured G3 alloy plate, the annealing temperature was 430°C±5°C, the holdin...

Embodiment 2

[0034] In this embodiment, the steps of the method for improving the pitting corrosion resistance of the G3 alloy plate by utilizing the preferred distribution of close-packed crystal planes are as follows:

[0035] (1) The G3 alloy plate is subjected to solution treatment, the solution temperature is 1100°C±5°C, the holding time is 40min, and the water is cooled to room temperature after the holding.

[0036] (2) Carry out pre-deformation treatment to the G3 alloy plate after solution treatment, the pre-deformation method is cold rolling, and the rolling amount is 35%;

[0037] (3) Detexturize the pre-deformed sheet at a temperature of 1120°C ± 5°C, hold for 15 minutes, and cool to room temperature with water after the hold.

[0038] (4) Texturing the de-textured G3 alloy plate by cold rolling with a rolling weight of 60%.

[0039] (5) Stress-relief annealing was performed on the textured G3 alloy plate, the annealing temperature was 450°C±5°C, the holding time was 90min, an...

Embodiment 3

[0042] In this embodiment, the steps of the method for improving the pitting corrosion resistance of the G3 alloy plate by utilizing the preferred distribution of close-packed crystal planes are as follows:

[0043] (1) The G3 alloy plate is subjected to solution treatment, the solution temperature is 1080°C±5°C, the holding time is 35min, and the water is cooled to room temperature after the holding.

[0044] (2) Carry out pre-deformation treatment to the G3 alloy plate after solution treatment, the pre-deformation method is cold rolling, and the rolling amount is 33%;

[0045] (3) Detexturize the pre-deformed sheet at a temperature of 1110°C±5°C, hold for 12 minutes, and cool to room temperature with water after the hold.

[0046] (4) Texturing the de-textured G3 alloy plate by cold rolling with a rolling weight of 55%.

[0047] (5) Stress-relief annealing was performed on the textured G3 alloy plate, the annealing temperature was 440°C±5°C, the holding time was 80min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com