PLC multi-point synchronous three-dimensional hydraulic bridge jacking system and jacking method

A jacking and hydraulic technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as insufficient synchronization accuracy, difficult control of jacking and closing accuracy, complex construction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

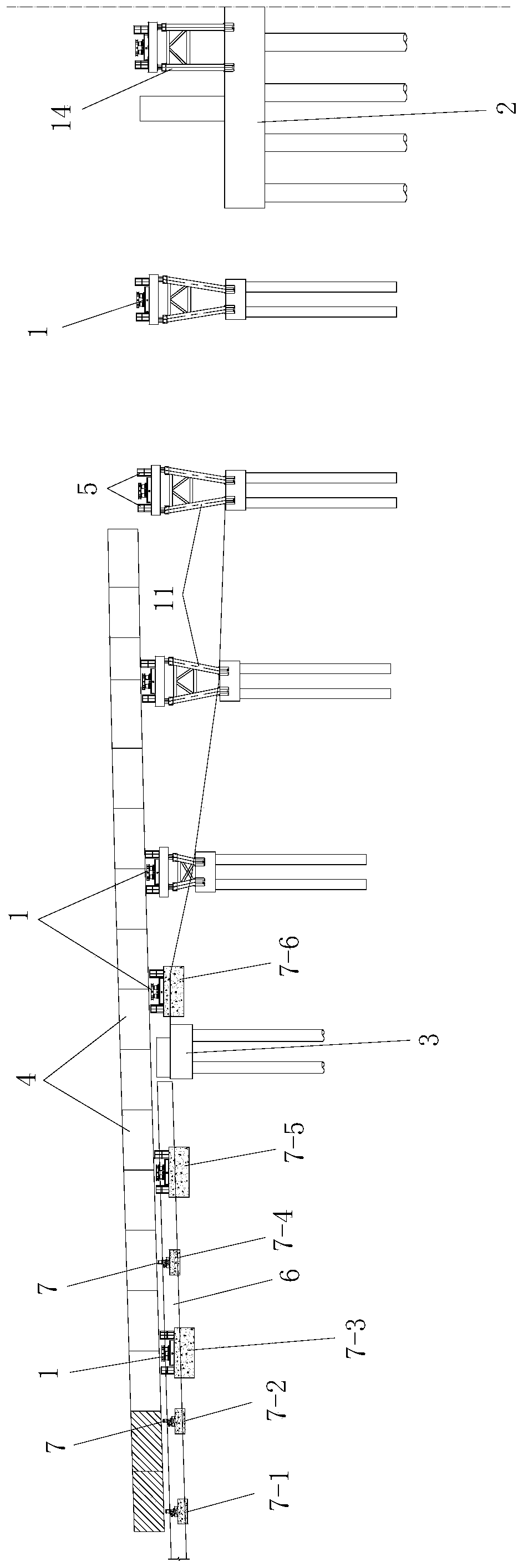

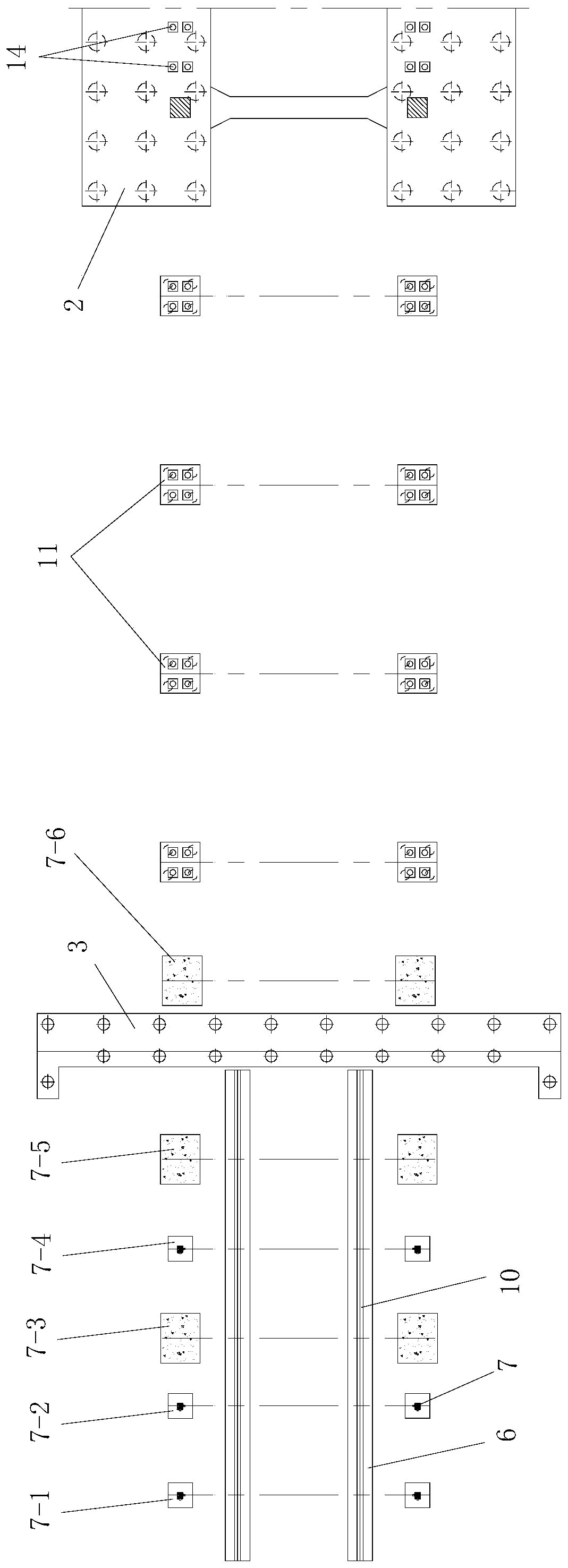

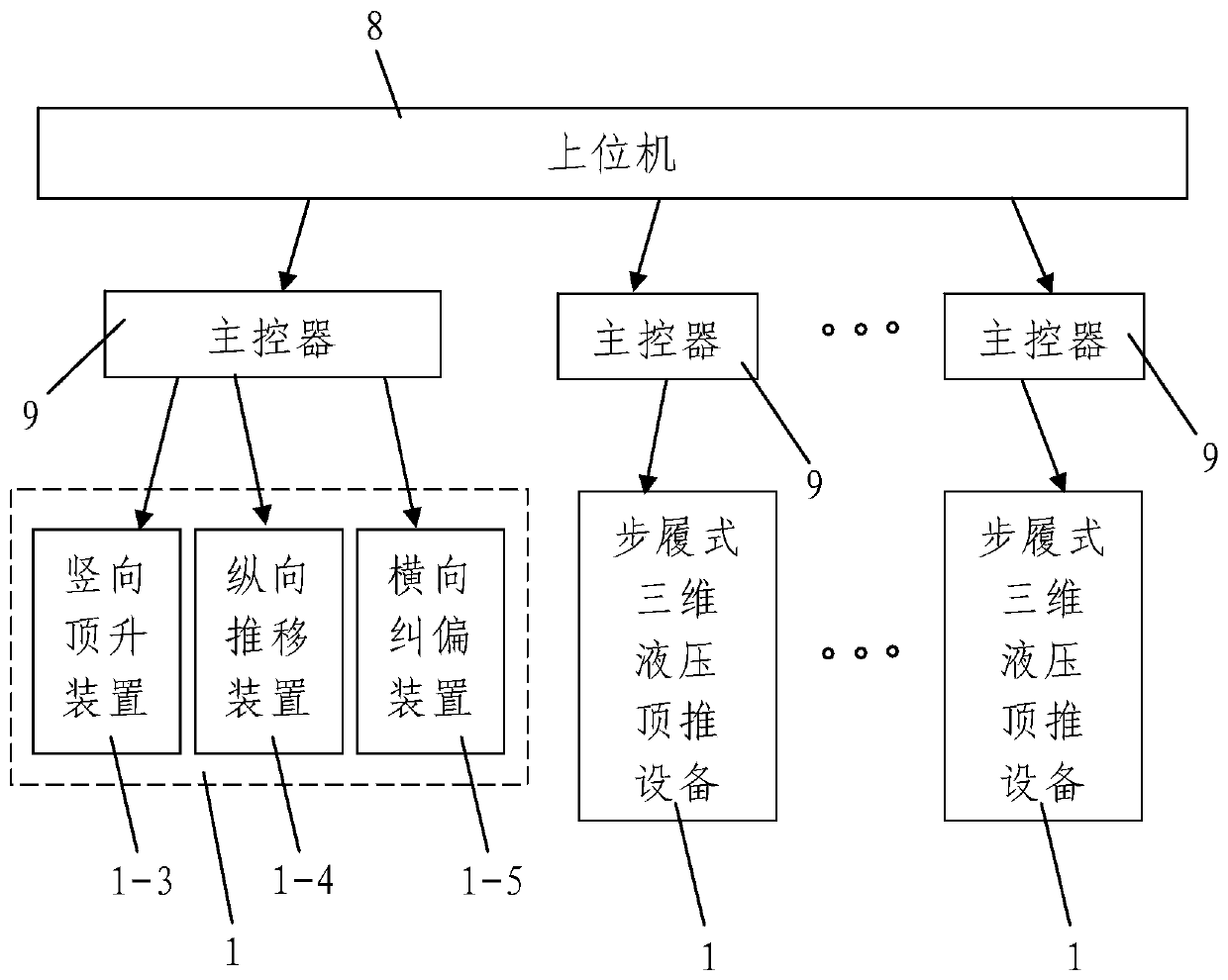

[0101] Such as figure 1 , figure 2 A PLC multi-point synchronous three-dimensional hydraulic bridge jacking system shown is characterized in that it includes a jacking monitoring system and multiple sets of walking-type three-dimensional hydraulic jacking equipment 1 for pushing the steel box girder to be pushed, and multiple sets The walking three-dimensional hydraulic pushing equipment 1 is laid out from front to back along the length direction of the pushed steel box girder; A steel box girder spliced from front to back by a plurality of steel box girder segments 4, the mid-span pier 2 and beam end pier 3 are permanent pier arranged vertically and both are steel bars Concrete pier, the front end of the pushed steel box girder is supported on the mid-span pier 2 and its rear end is supported on the beam end pier 3; The length direction of the pushing steel box girder is provided with a plurality of temporary buttresses 11 supporting the pushed steel box girder from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com