Method for ceaselessly conducting cast-in-place box girder reset and support replacement

A technology of bearings and box girders, applied in bridges, bridge parts, bridge maintenance, etc., can solve problems affecting the production and operation of surrounding units, eccentric pressure on pier tops, and beams that cannot be reset, so as to eliminate potential safety hazards and save construction Effects of cost and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

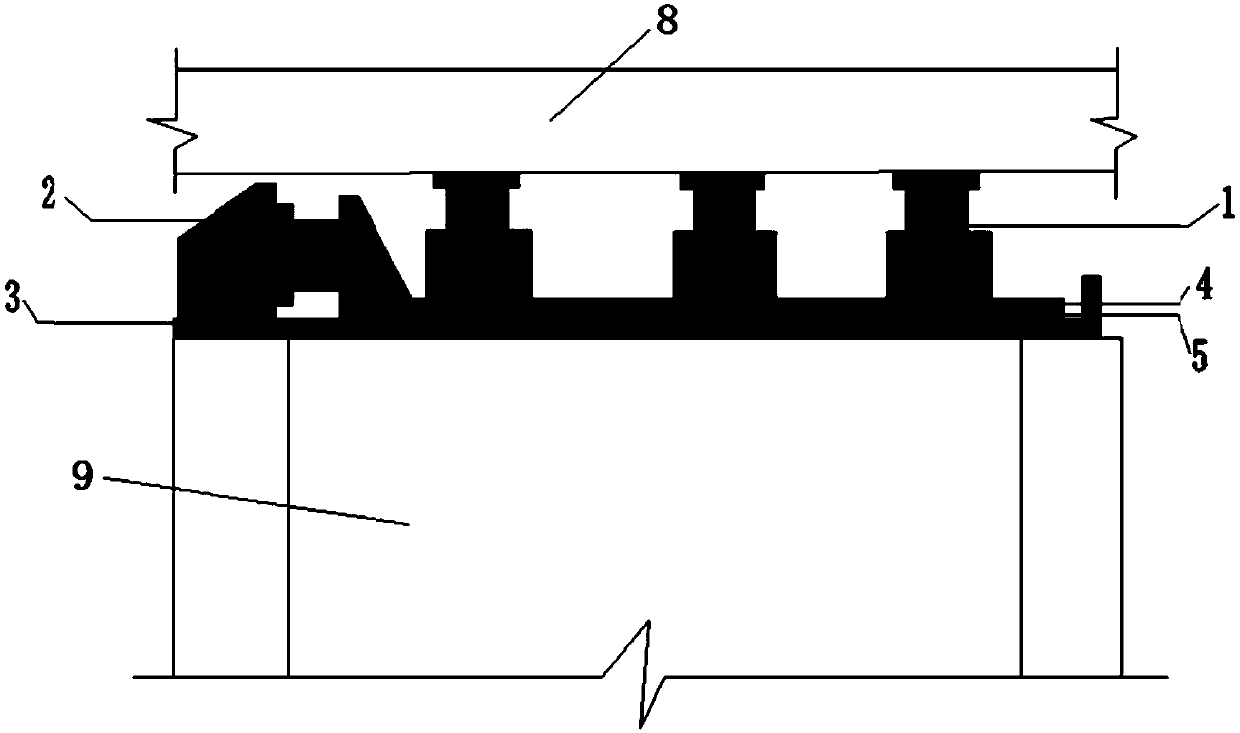

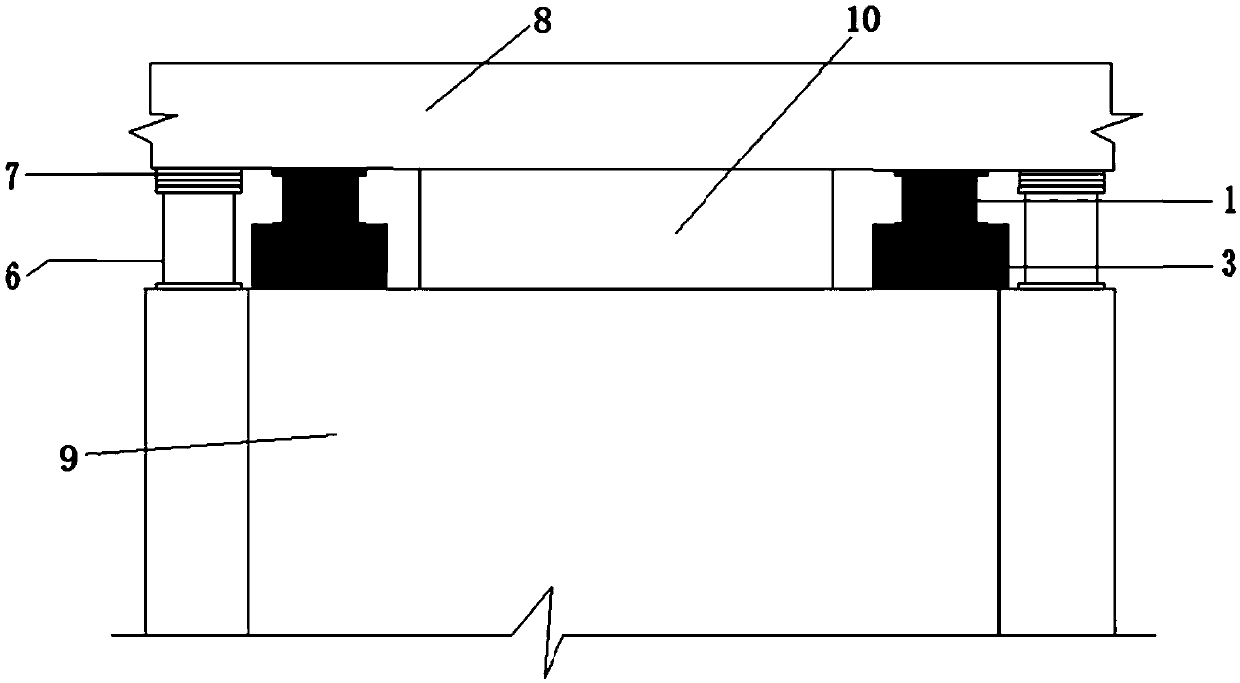

[0033] A bridge maintenance project, the bridge is 1209.46m long and 26.5m wide, the main bridge is a variable cross-section prestressed concrete continuous box girder, and the east-west approach bridge is a cast-in-place prestressed concrete continuous box girder with a beam height of 1.8m and a single box with five rooms.

[0034] The first (4×32.7) m and second (3×32.7) m of the west approach bridge of the bridge displaced 8.2 cm and 4.6 cm toward the abutment respectively, resulting in the failure of multiple support bolts of the two box girders and the limit Lateral shedding, pier column eccentric compression, there are potential safety hazards.

[0035] The method for resetting the cast-in-place box girder and replacing the support by adopting the continuous delivery described in this embodiment includes the following steps:

[0036] (1) Set up double-row floor-to-ceiling scaffolds around the pier columns. The scaffolding adopts fastener-type steel pipe scaffolding; Bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com