Intelligent integrated automatic construction factory

An intelligent, factory-based technology, which is applied to the processing of building materials, construction, and building structures, can solve problems that affect the normal progress of construction, affect construction efficiency, and have inconspicuous results. It can shorten the construction period, reduce the number of parts, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

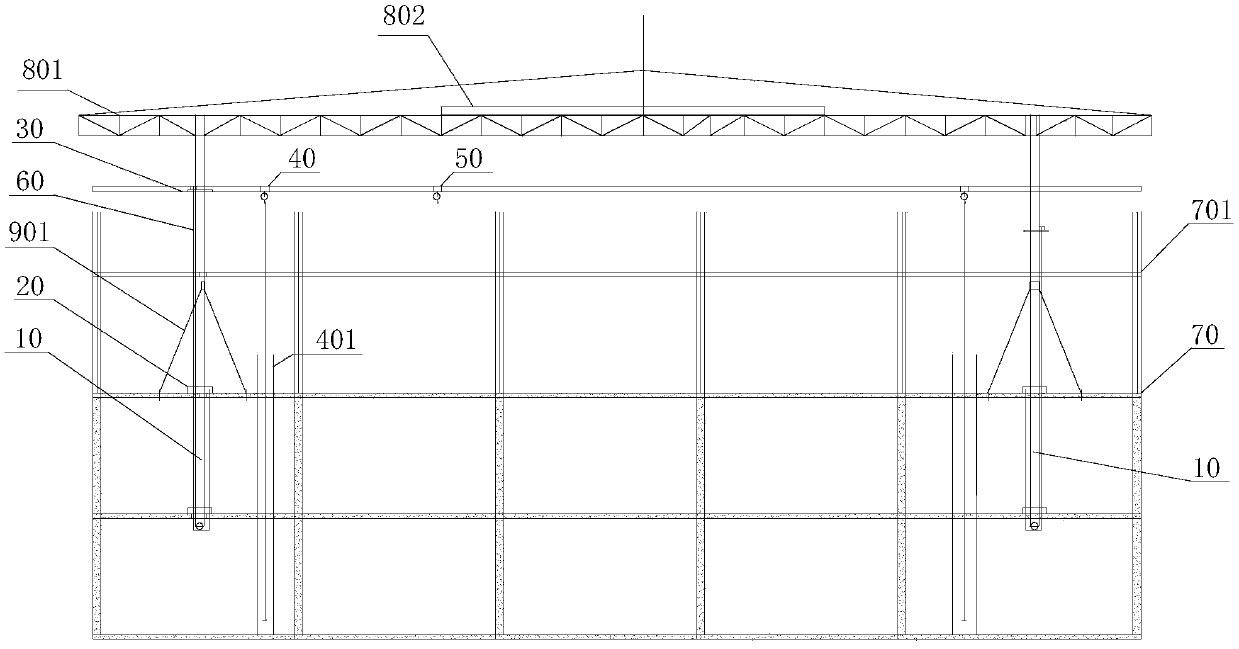

[0021] In this example, if figure 1 As shown, the intelligent integrated automated construction factory includes: an installation structure, the installation structure is installed on the floor 70 where the concrete pouring is completed, the installation structure includes a lifting guide rail 10, the lifting guide rail 10 is vertically arranged and slidably assembled on the floor 70 where the concrete pouring is completed, The lifting guide rail 10 can reciprocate in the height direction under the action of an external force; the transfer assembly, the transfer assembly includes: a horizontal moving guide rail 30, a material vertical transfer device 40 and a material horizontal transfer device 50; the horizontal moving guide rail 30 is installed on the lifting guide rail 10 , the material vertical transfer device 40 is installed on the horizontal moving guide rail 30, the material vertical transfer device 40 is used to realize the transfer of the material in the vertical direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com