A pipeline system without disassembly and assembly by pipe jacking machine and its construction method

A pipeline and machine-free technology, applied in the pipe jacking machine disassembly-free pipeline system and its construction field, can solve the problems of frequent disassembly and assembly, low construction efficiency, etc., and achieve the effects of eliminating potential safety hazards, saving costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

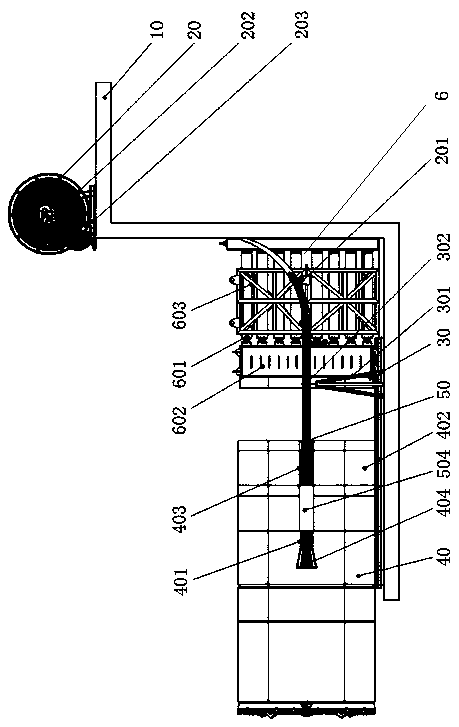

[0031] Example 1, such as Figure 1~3 As shown, a pipe jacking machine without disassembly and assembly pipeline system includes a shield body 40, a pipe joint 402, a pushing device 6, a pipeline retracting device 20 and a guide device 30, and the pushing device 6 pushes the pipe joint 402 and the shield body 40 Moving forward, the pipeline retractable device 20 is wound with a pipeline 201, the pipeline retractable device 20 is used for retracting the pipeline 201, the outer wall of the shield body 40 is provided with a shield wire groove 401, and the outer wall of the pipe joint 402 The pipe section wire groove 403 is arranged on the top, and the pipe section wire groove 403 is connected with the shield body wire groove 401. The pipeline 201 passes through the guide device 30 and extends into the shield body 40 through the pipe section wire groove 403 and the shield body wire groove 401. The guide device 30 is used for the pipeline to orientate into the pipe section wire gro...

Embodiment 2

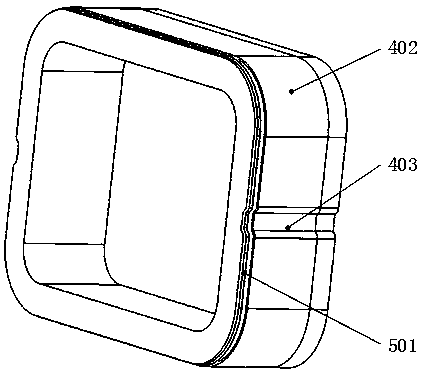

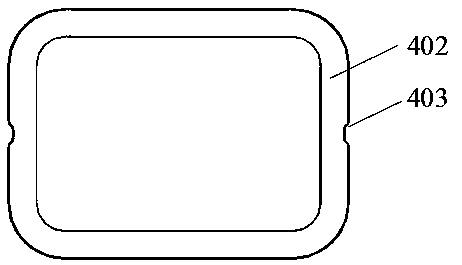

[0034] Example 2, such as Figure 4~5 As shown, a pipeline system without disassembly and assembly of a pipe jacking machine, the seal 50 includes an elastic sealing water-stop ring 501 arranged between the shield body 40 and the pipe joint 402, which is used for sealing and waterproofing, and the shield body Both the wire groove 401 and the pipe section wire groove 403 are provided with a wire groove cover plate 504, and the shield body wire groove 401 and the pipe joint wire groove 403 are equipped with cover plate sealing strips 505 symmetrically up and down, and the wire groove cover plate 504 is connected with the cover plate The sealing strip 505 is a sealing fit. The wire channel cover plate 504 is pasted on the outer edges of the pipe section wire channel 403 and the shield body wire channel 401 by an adhesive, and is used for sealing the pipe section wire channel 403 and the shield body wire channel 401 .

[0035] further, such as Figure 8~9 As shown, the shield wi...

Embodiment 3

[0038]Embodiment 3, a pipeline system without disassembly and assembly of a pipe jacking machine, a construction method of a pipeline system without disassembly and assembly of a pipe jacking machine, including the following steps: S1: Paste a cover plate with an adhesive in the wire channel 401 of the shield body and seal it The strip 505 and the lower sealing rubber block 503 install the pipeline joint 404 in the shield wire groove 401; the pipeline joint 404 is welded on the shield body 40 for fixing the pipeline 201 in the trapezoidal groove 401 of the shield body and the shield body 40 of the shield machine , to prevent falling off;

[0039] S2: Paste the cover plate sealing strip 505 and the lower sealing rubber block 503 with an adhesive in the pipe joint wire channel 403, and paste the elastic sealing water stop ring 501 on the pipe joint 402. This step can be implemented after the pipe joint 402 is prefabricated , that is, this process is completed before hoisting, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com