X-type composite rocket inter-stage section or inter-box section connecting structure

A composite material and connecting structure technology, applied in the direction of weapon types, projectiles, self-propelled projectiles, etc., can solve the problems of difficult coordination and assembly, rod and rod cannot support each other, etc., and achieve good assembly process, high load bearing, and improved structure. The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

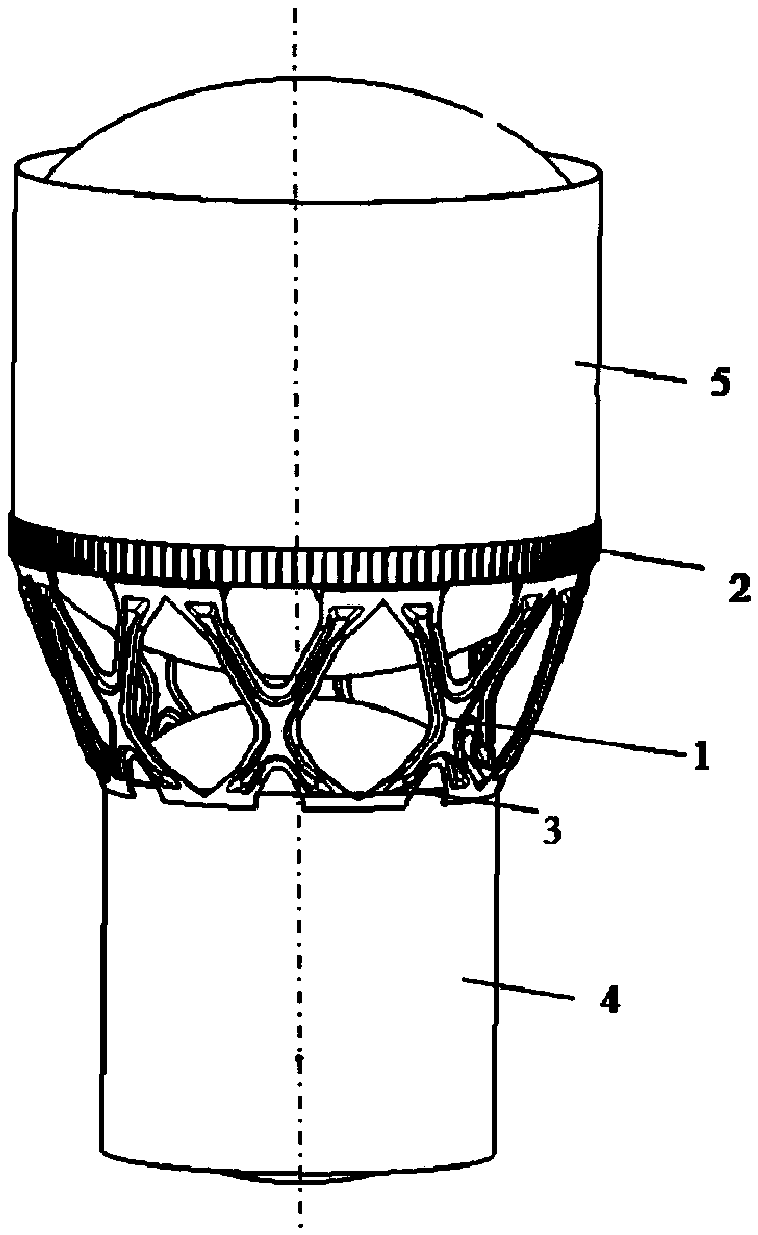

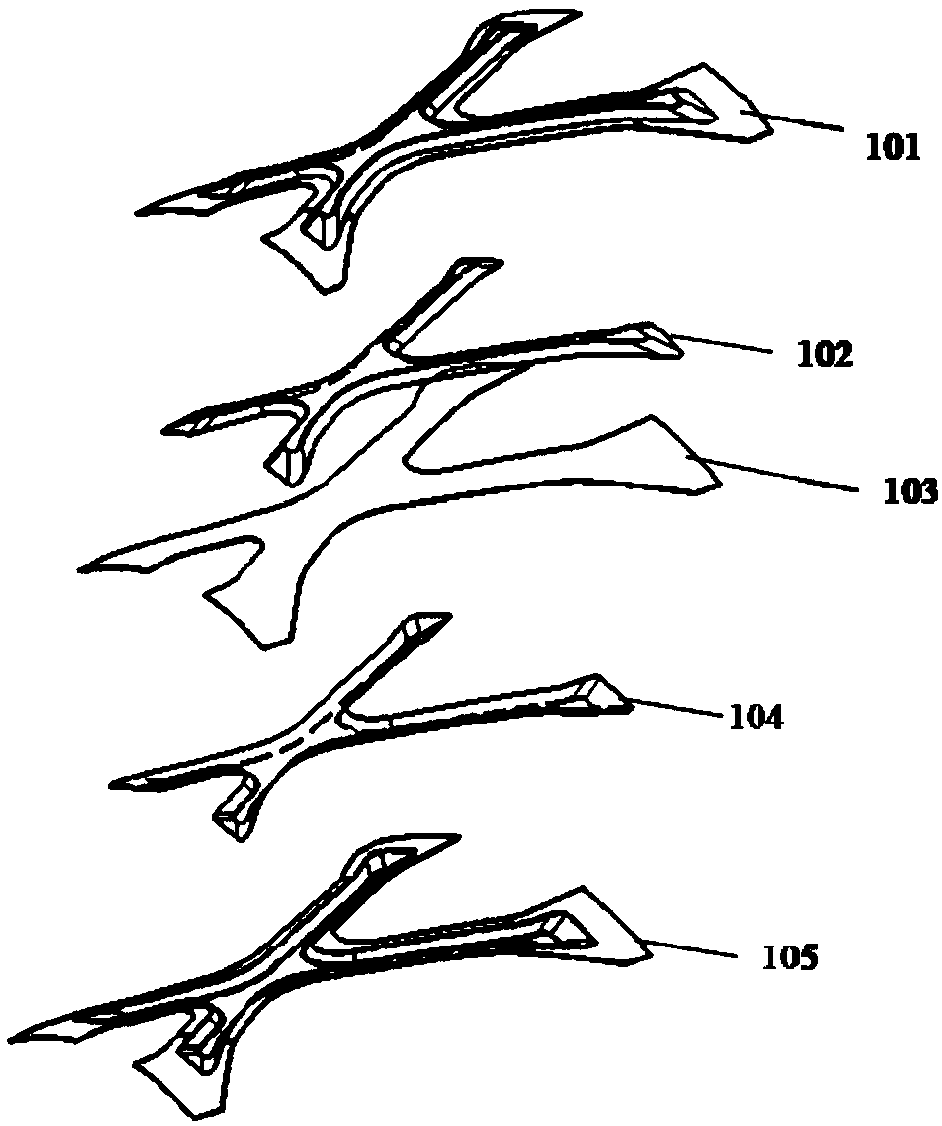

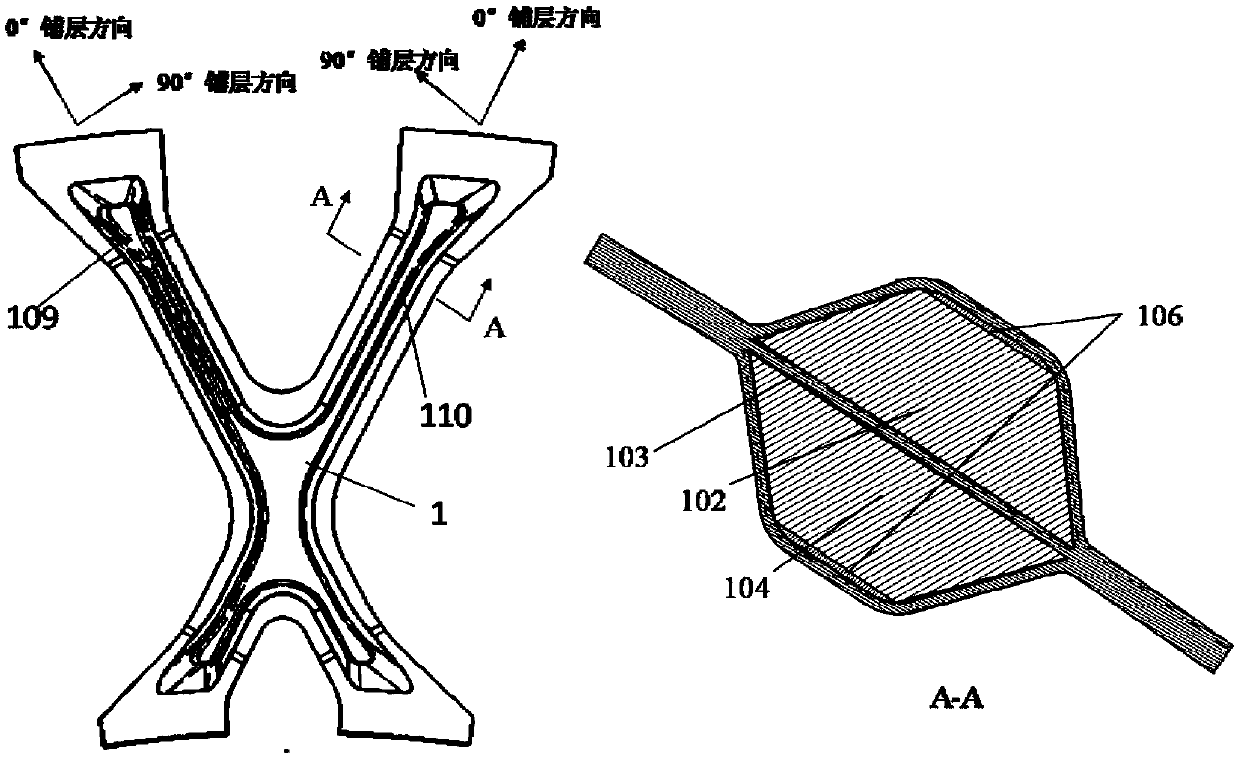

[0032] The present invention is an X-type composite material rocket inter-stage or inter-tank connection structure, comprising: a plurality of X-shaped inter-stage or inter-chamber connectors (1), front tank rear short shells (2) (also known as It is the front tank / rocket body rear short shell structure (2)), the rear tank front short shell (3) (also known as the rear tank / rocket body front short shell (3)); multiple X-type interstage sections Or the inter-chassis connectors (1) are uniformly arranged around the rocket axis to form a ring structure, and the X-shaped inter-stage or inter-chassis connectors (1) are preferably made of carbon fiber composite materials and PMI foam interlayers to achieve high load-carrying , Low thermal conductivity function. The X-type interstage section or box section connector (1) consists of an outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com