Multi-connection experiment system and experiment method thereof

An experimental system and experimental technology are applied in the direction of material inspection, suspension and porous material analysis, and the use of stable tension/pressure to test the strength of materials. progress and other issues, to achieve the effect of speeding up the progress of experimental research, shortening the experimental research cycle, and simplifying the composition mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

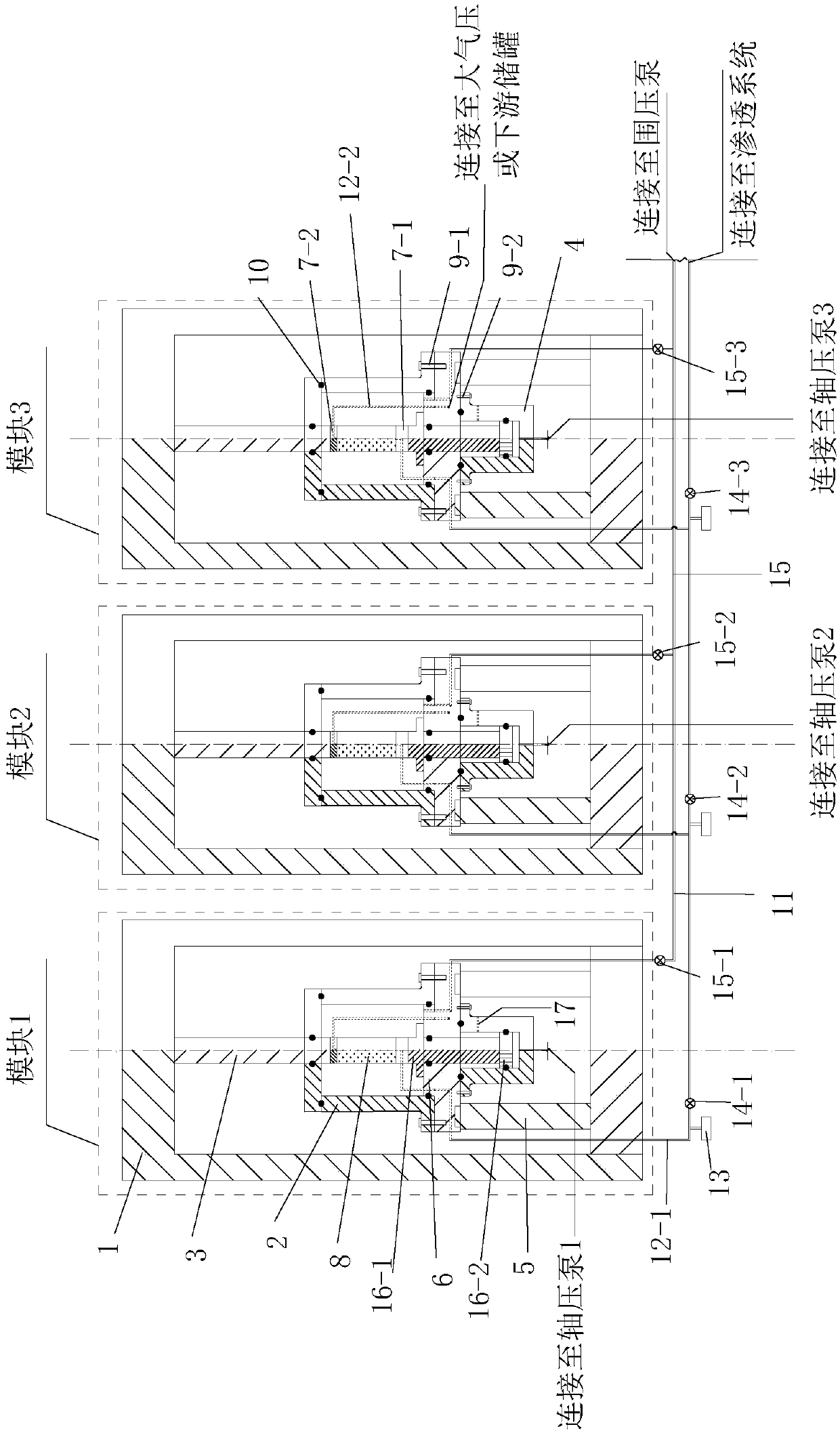

[0034] The experimental system described in this embodiment is composed of 3 test units, and each experimental structure includes a rectangular portal frame 1, a triaxial chamber 2, an axial pressure chamber 4, an upper pressing rod 3, an axial loading member 16-1, and a balance platform 6. Support column 5 constitutes;

[0035] The support column is fixed on the bottom of the rectangular frame, and the balance platform is fixed and supported horizontally by the support column. The triaxial chamber and the axial pressure chamber are cylindrical components with one end closed, and are respectively fixed on the upper and lower surfaces of the balance platform and the balance state. Enclosing a closed space, the end edges of the triaxial chamber and the axial pressure chamber in contact with the balance platform are provided with flanges for setting bolt holes so that they can be fixed together with the balance platform with bolts. The balance table is a cylindrical member with a...

Embodiment 2

[0039] Example 2: Triaxial elongation experiment

[0040] 1. Lift the triaxial chamber 2 to the top of the portal frame 1, install the prepared cylindrical rock sample 8 on the axial loading member 16-1 (place the upper and lower indenters at the upper and lower ends of the rock sample), and use The fluorochlororubber membrane wraps the rock sample 8, the axial loading member 16-1 and the upper pressing rod 3 at the same time, and the upper and lower ends of the fluorochlororubber membrane are clamped with a retractable hoop to prevent the infiltration of confining pressure oil;

[0041] 2. Lower the triaxial chamber 2 to the balance table 6, lock the anchor screw 9-1 of the triaxial chamber, and open the confining pressure cut-off valves 15-1, 15-2, 15-3 (here, if only one test is carried out in a batch) In this way, you only need to open any one of the confining pressure cut-off valves), and use the confining pressure pipeline 11 to fill the triaxial chamber with confining p...

Embodiment 3

[0044] Embodiment 3: Rock seepage creep experiment

[0045] 1. Lift the triaxial chamber 2 to the top of the portal frame 1, install the prepared cylindrical rock sample 8 on the sample lower indenter 7-1 and the sample upper indenter 7-2, and place them On the axial loading member 16-1, the rock sample 8, the sample lower indenter 7-1 and the sample upper indenter 7-2 are simultaneously wrapped with a fluorochlororubber film, and the fluorochlorohydrin is tightened with a stretchable hoop. The upper and lower ends of the rubber membrane prevent the infiltration of confining pressure oil;

[0046] 2. Lower the triaxial chamber 2 to the balance table 6, lock the anchor screw 9-1 of the triaxial chamber, open the confining pressure stop valves 15-1, 15-2, 15-3, and use the confining pressure pipeline 11 to flow into the triaxial chamber. full of confining oil;

[0047] 3. Use the axial pressure pump and the confining pressure pump to apply axial pressure σ to the sample respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com