Integrated modular system

A modular and integrated technology, applied in instrumentation, geometric CAD, calculation, etc., can solve the problems of lengthened space vehicle assembly cycle, cumbersome and complicated docking installation operations, high economic cost, etc., to simplify the external installation interface, The effect of reducing economic cost and time cost and improving the utilization rate of layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

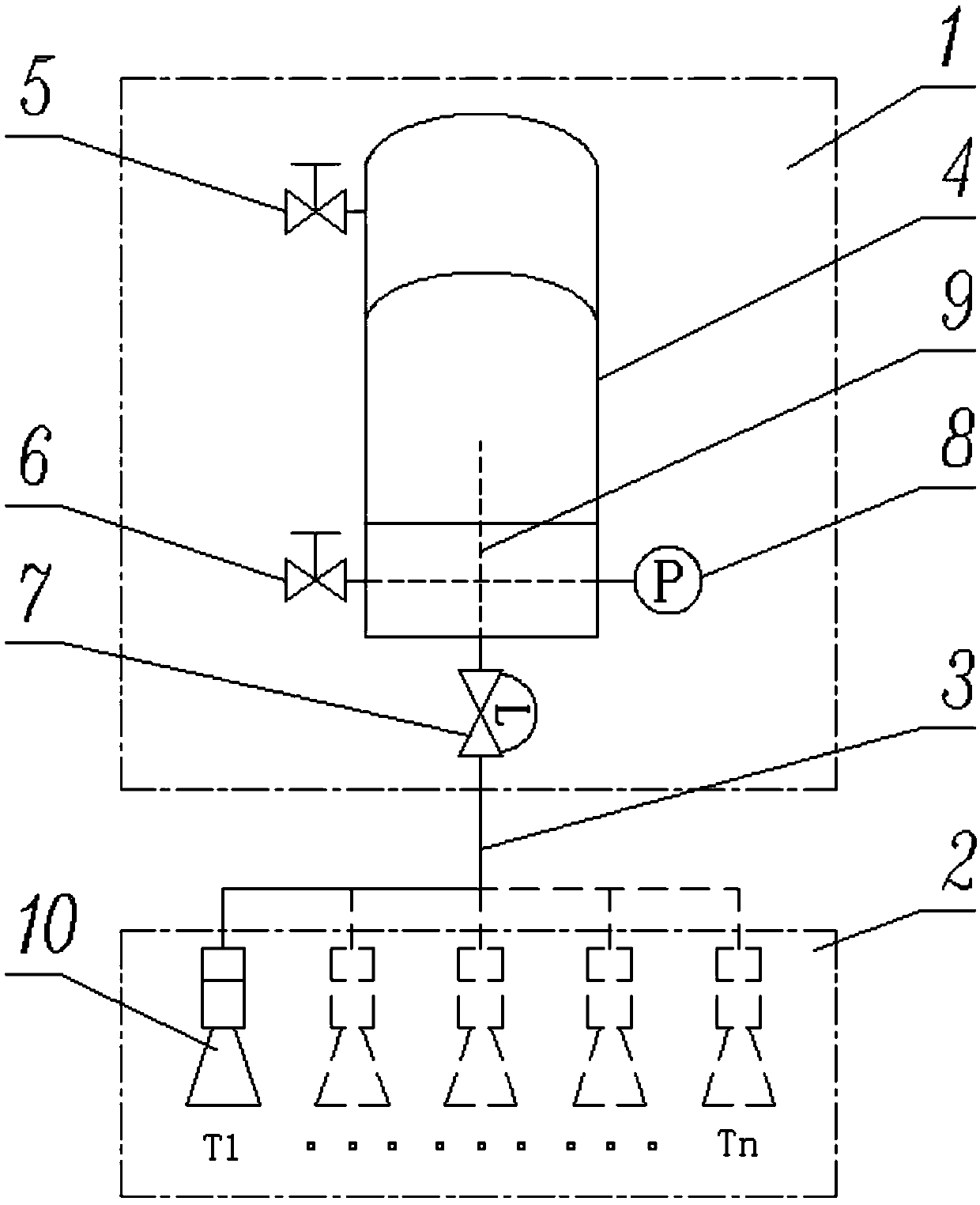

[0020] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0021] like figure 1 As shown, the present invention provides an integrated modular system, comprising: a storage and supply module 1, an output module 2 and an inter-module conveying channel 3, and after the storage and supply module 1, the output module 2 and the inter-module conveying channel 3 are integrated, The module form is installed and docked with the main structure, and the conveying channel 3 connects the inner cavity channel of the storage and supply module 1 and the output module 2 to realize the conveying of the working medium from the storage and supply module 1 to the output module 2, wherein,

[0022] The storage and supply module 1 is integrated with: a storage and discharge container 4, a charge and exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com