Modifier for resin, and resin composition using same

A modifier and resin technology, applied in the field of resin modifiers and resin compositions using it, can solve the problems of high moisture permeability, polarizer deterioration, etc., and achieve excellent anti-bleeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

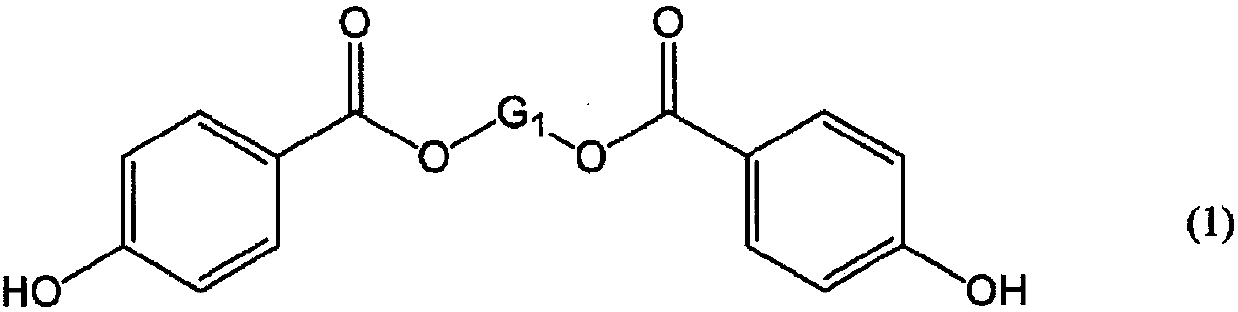

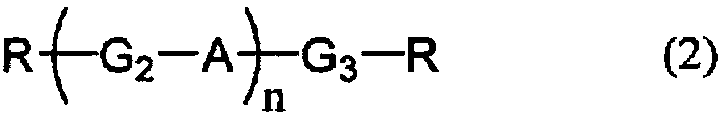

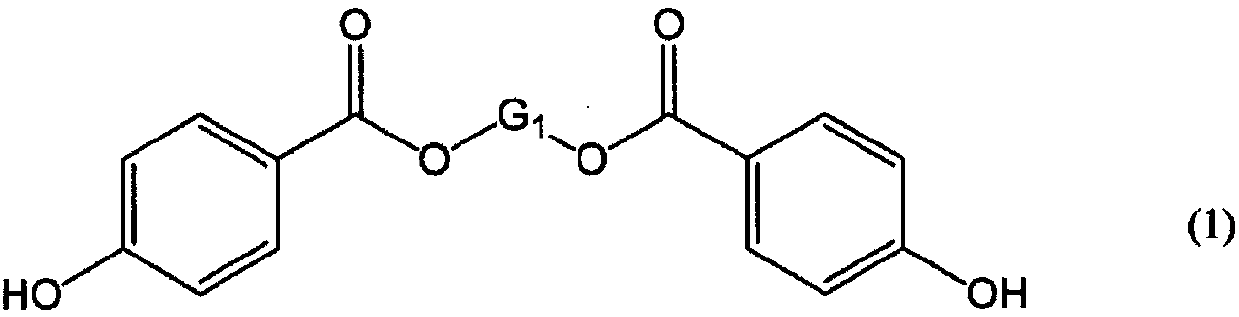

Method used

Image

Examples

Embodiment 1~15 and comparative example 1~9

[0091] Using the compounds shown in the following Tables 1 to 6, diester compounds and oligoester compounds were synthesized, and resin modifiers were prepared using the obtained diester compounds and oligoester compounds. Using this modifier, the bleeding resistance, moisture resistance (moisture permeability), optical properties (retardation change value) and dimensional stability were evaluated according to the following procedures. In addition, the measurement of the number average molecular weight was performed by the following procedure. In addition, the numerical value in the parenthesis shown in Tables 1-6 is mol%.

[0092]

[0093]The resin modifiers of Examples and Comparative Examples were dissolved in tetrahydrofuran (THF) to prepare 0.5% by mass sample solutions, and the number average molecular weight was measured using gel permeation chromatography (GPC) under the following conditions. In addition, the calibration curve was created using polystyrene (molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com