Meshed ultrathin metal bipolar plate and three-dimensional flow field thereof

An ultra-thin metal, bipolar plate technology, used in fuel cells, electrochemical generators, electrical components, etc., can solve the problem of fuel cells not being able to cool, and achieve the effects of increasing volume power density, reducing thickness, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

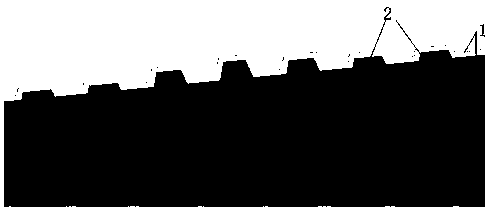

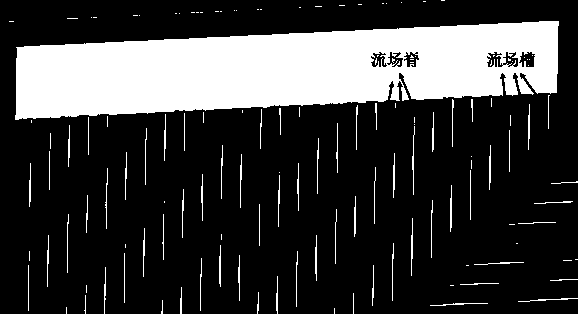

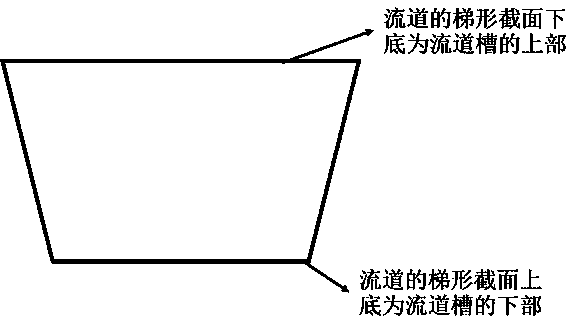

[0021] An intermeshed ultra-thin metal bipolar plate, including two metal single-stage plates 1, on which there are multiple concave flow channels 2, the flow channels 2 serve as flow field grooves, and the gap between adjacent flow channels 2 The part in between is the flow field ridge, the cross section of the flow channel 2 along the width direction is trapezoidal, and the cross section along the length direction is wave, the flow field grooves and flow field ridges of the two metal single-stage plates 1 alternate, that is, a single pole The portion of the plate flow field groove corresponds to the portion of the other unipolar plate flow field ridge, and the two metal single stage plates mesh at the "troughs" of the "wave". The wave equation is a sine function or a cosine function, in this embodiment it is a sine function.

[0022] Its processing method is as follows:

[0023] Step 1. Use a metal plate with a thickness of 0.1mm as the metal single-stage plate base materia...

example 2

[0033] In this embodiment, the wave-shaped equation is a cosine function.

[0034] Step 1. Use a metal plate with a thickness of 0.1mm as the base material;

[0035] Step 2. The design of the metal bipolar plate flow field is as follows:

[0036] ①The cross-section of the flow channel is trapezoidal and wavy;

[0037] ②The length of the upper bottom of the isosceles trapezoidal section is 0.6mm, and the length of the lower bottom is 1mm, that is, the surface groove width of the flow field plate is 1mm, and the ridge width is 0.6mm; mm, minimum depth 0.2mm;

[0038] Step 3. Design the drawing of the flow field plate opposite to the position of the flow field groove and flow field ridge in step 2;

[0039] Step 4. Based on the designs in steps 2 and 3, process corresponding stamping dies respectively;

[0040] Step 5. respectively use the mold in step 4 to stamp the metal sheet in step 1;

[0041] Step 6. Use the two unipolar plates punched out based on steps 2 and 3, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com