System and method for preparing adsorption material by using sludge

A technology for adsorbing materials and sludge, applied in chemical instruments and methods, sludge treatment, pyrolysis treatment of sludge, etc., to achieve the effects of energy saving, environmental protection, high added value, resource utilization, and solving dehydration difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

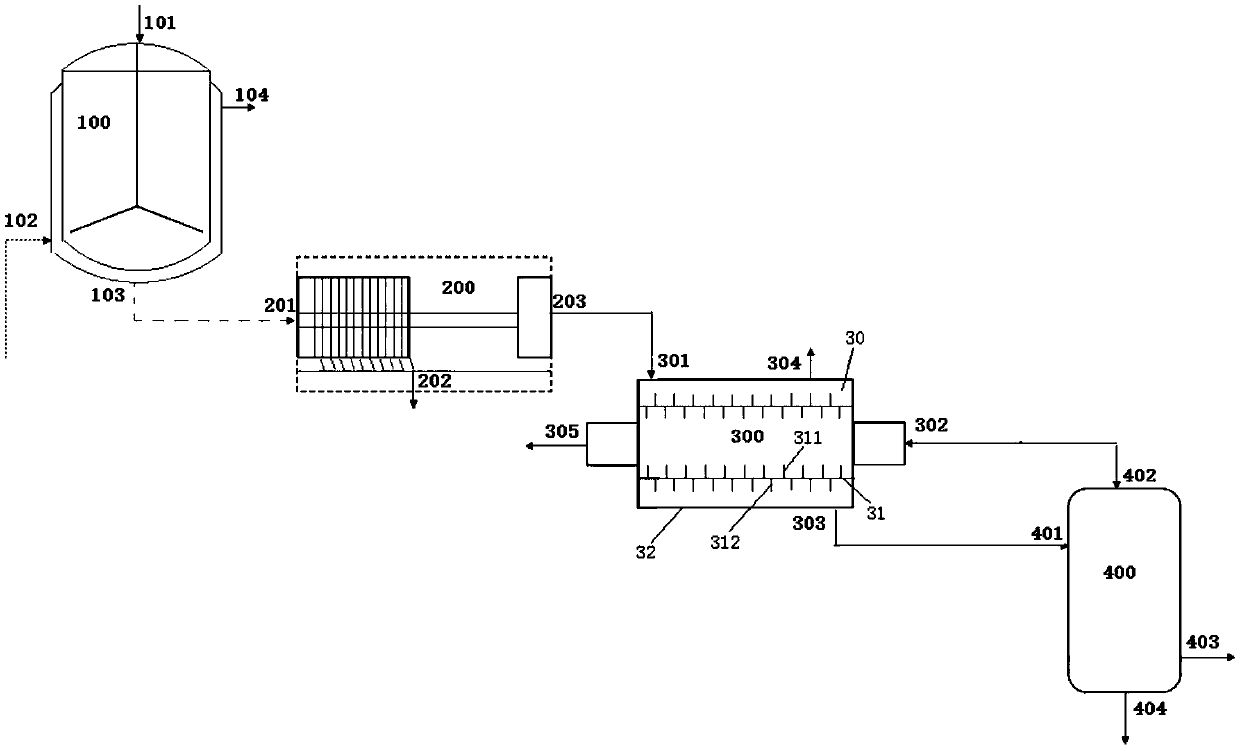

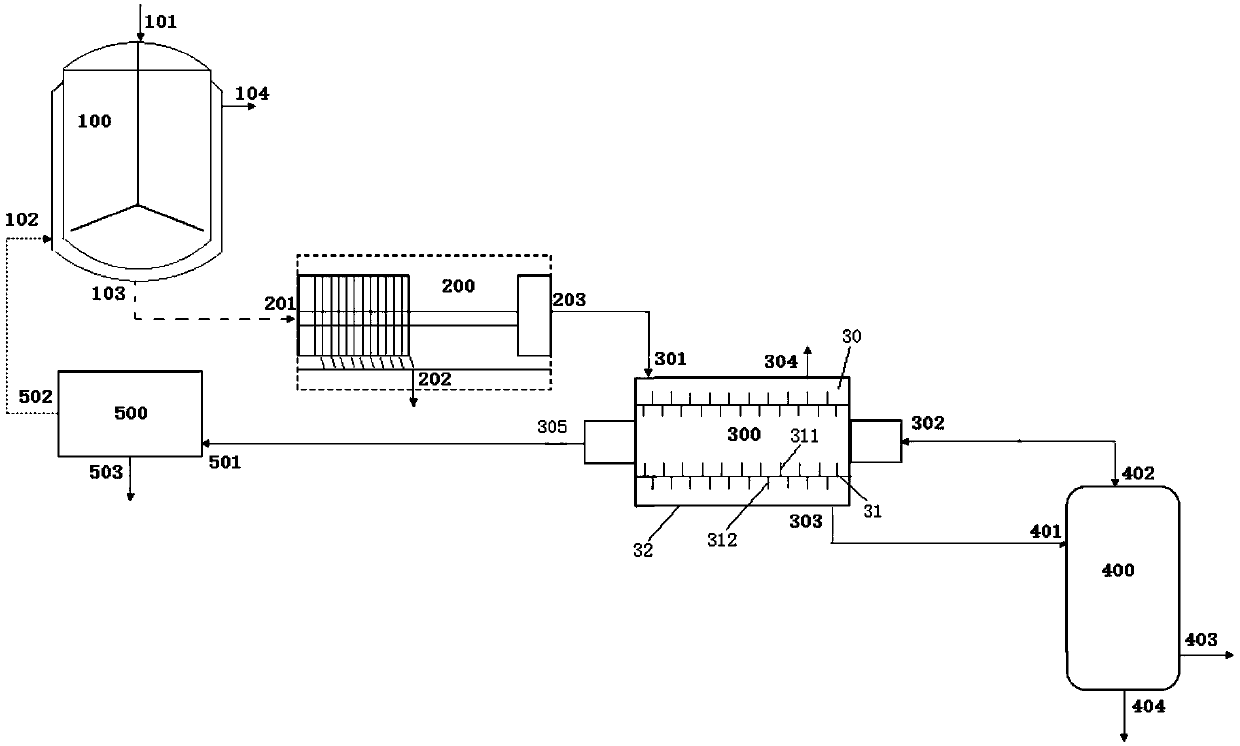

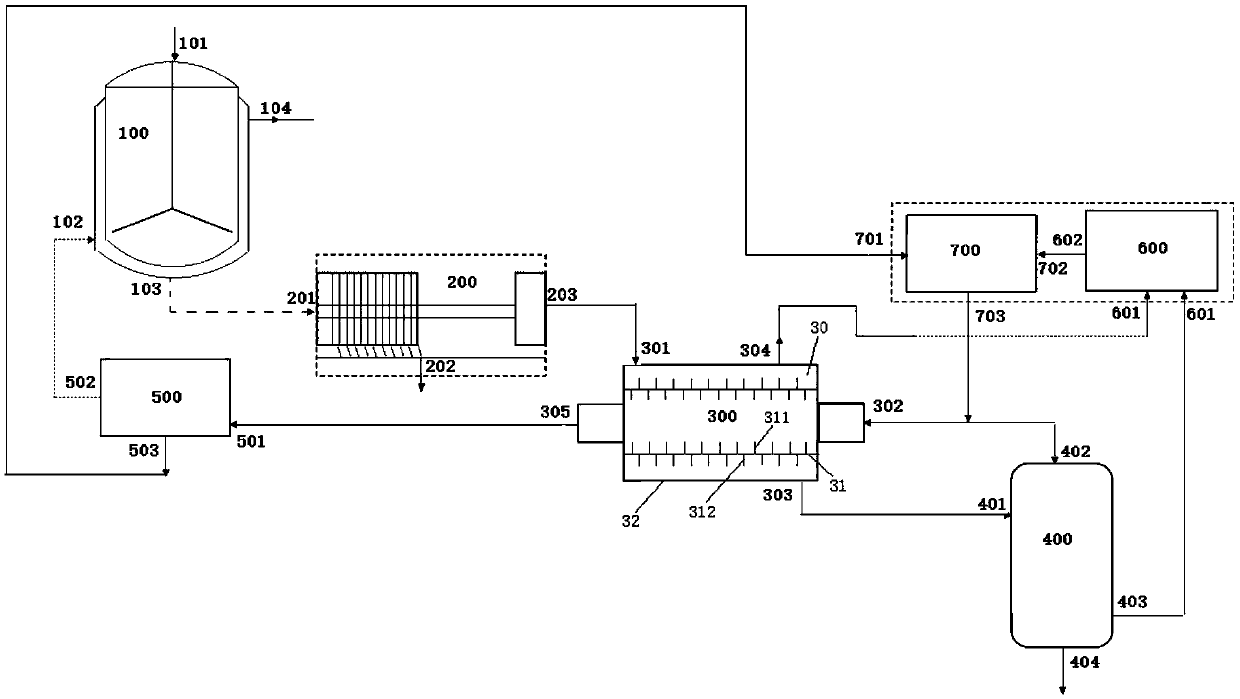

[0083] Put municipal sludge with a water content of 85wt% in a hydrothermal reaction device, and treat it for 120 minutes under high-temperature water vapor at 160 degrees Celsius and 1.5 MPa. After the treatment, the sludge is pumped into the buffer tank, and after conditioning, it is poured into the plate frame Filter press, filter under 1.5MPa pressure for 5 hours to obtain sludge with a water content of 40wt%, and then enter the sludge pyrolysis device after being crushed to ≤5mm; the filtrate obtained by press filtration contains a large amount of K, N, P, After collection, it can be diluted and used as organic compound fertilizer; after crushing, the sludge is pyrolyzed in a pyrolysis furnace at 500 degrees Celsius for 90 minutes (hot air temperature is 850 degrees Celsius) to obtain pyrolysis gas oil, pyrolysis carbon and hot air after heat exchange (350- 450 degrees Celsius), the pyrolysis oil gas is directly reused as fuel in the burner to generate high-temperature flu...

Embodiment 2

[0085] Put municipal sludge with a water content of 90wt% in a hydrothermal reaction device, and treat it for 30 minutes under high-temperature water vapor at 200 degrees Celsius and 2.5 MPa. After the treatment, the sludge is pumped into the buffer tank, and after conditioning, it is poured into the plate frame Filter press, filter under 2MPa pressure for 4 hours to obtain sludge with a water content of 35wt%, and then enter the sludge pyrolysis device after being crushed to ≤5mm; the filtrate obtained by press filtration contains a large amount of K, N, P, collected After that, it can be diluted and used as organic compound fertilizer; after crushing, the sludge is pyrolyzed in the pyrolysis furnace at 650 degrees Celsius for 45 minutes (hot air temperature is 950 degrees Celsius), to obtain pyrolysis gas oil, pyrolysis carbon and hot air after heat exchange (400-450 degrees Celsius) Celsius), the pyrolysis oil gas is directly reused as fuel in the burner to generate high-tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com