A kind of preparation method of shredded tobacco stem

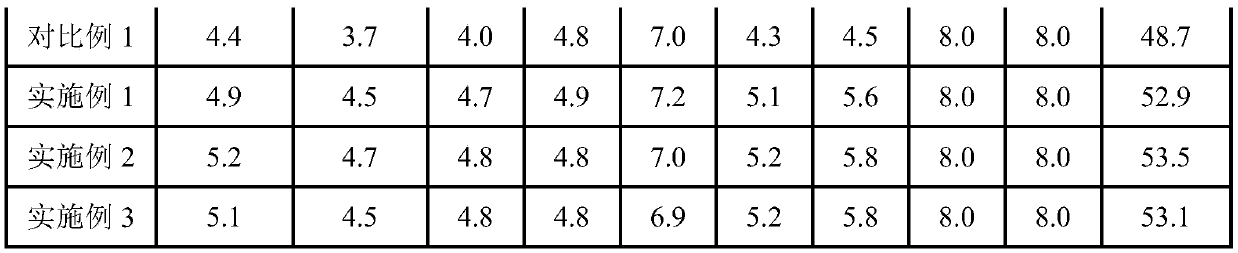

A technology for tobacco cut stems and tobacco products, which is applied in the process of rolling or defibrating tobacco stems, tobacco and tobacco cut stem preparation fields, and can solve the problems affecting the compatibility between cut stems and cut leaves and the uniformity and uniformity of component mixing. The degree, fullness, and vividness need to be improved, and the physical shape of the leaf silk is very different, so as to achieve the effect of outstanding physical quality indicators and sensory quality, high overall smoking quality, and rich tobacco flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

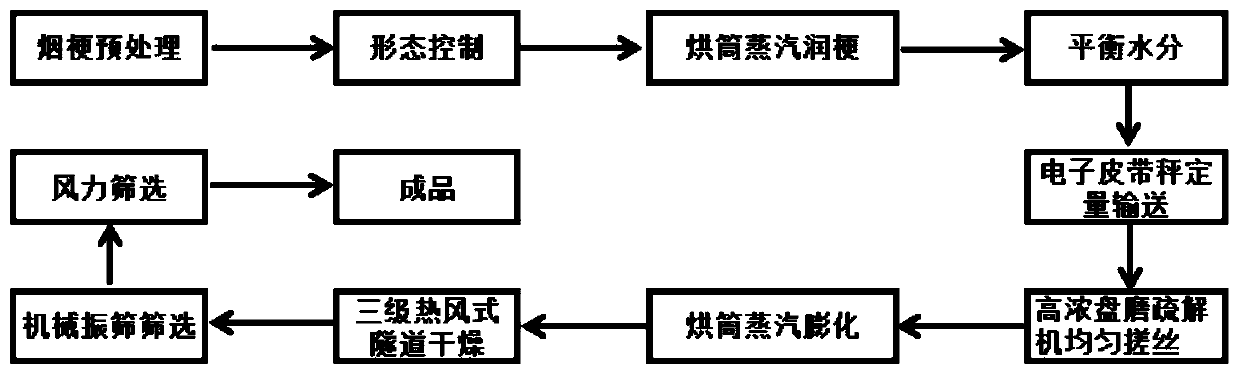

[0043] A method for preparing cut tobacco stems, comprising the following steps:

[0044] 1. Pretreat the tobacco stem raw material, and process the tobacco stem to a length of 2-4cm;

[0045] 2. Transport the tobacco stems with uniform shape to the drying cylinder, and pass in 0.1MP steam to moisten the stems;

[0046] 3. Evenly steam the tobacco stems to a moisture content of 35%, and balance the moisture for 180 minutes;

[0047] 4. Control the flow rate of 850kg / h to evenly feed the material to the JM600 high-consistency disc grinding machine for tobacco stem decompression and rolling;

[0048] 5. The fixed plate of JM600 high-concentration disc grinding machine is made of alloy steel (tooth shape is small H), and the moving plate is made of alloy sand (tooth shape is large H);

[0049] 6. Before turning on the deflagging machine, adjust the gap between the fixed plate and the moving plate to 0.40mm-0.50mm. When the defrosting starts, the speed is 900r / min. 1200r / min, k...

Embodiment 2

[0055] A method for preparing cut tobacco stems, comprising the following steps:

[0056] 1. Pretreat the tobacco stem raw material, and process the tobacco stem to a length of 2-4cm;

[0057] 2. Transport the tobacco stems with uniform shape to the drying cylinder, and pass in 0.3MP steam to moisten the stems;

[0058] 3. Evenly steam the tobacco stems to a moisture content of 40%, and balance the moisture for 240 minutes;

[0059] 4. Control the flow rate of 1200kg / h to evenly feed the material to the JM600 high-consistency disc grinding machine for tobacco stem decompression and rolling;

[0060] 5. The fixed plate of JM600 high-concentration disc grinding machine is made of alloy steel (tooth shape is small H), and the moving plate is made of alloy sand (tooth shape is large H);

[0061] 6. Before starting the deflaker, adjust the gap between the fixed plate and the moving plate to 0.40mm-0.50mm, and the speed to 900r / min. After keeping it for 2min, adjust the gap betwee...

Embodiment 3

[0067] A method for preparing cut tobacco stems, comprising the following steps:

[0068] 1. Pretreat the tobacco stem raw material, and process the tobacco stem to a length of 2-4cm;

[0069] 2. Transport the tobacco stems with uniform shape to the drying cylinder, and pass in 0.2MP steam to moisten the stems;

[0070] 3. Evenly steam the tobacco stems to a moisture content of 38%, and balance the moisture for 200 minutes;

[0071] 4. Control the flow rate of 1000kg / h and evenly feed the material to the JM600 high-concentration disc grinding machine for tobacco stem decompression and rolling;

[0072] 5. The fixed plate of JM600 high-concentration disc grinding machine is made of alloy steel (tooth shape is small H), and the moving plate is made of alloy sand (tooth shape is large H);

[0073] 6. Before starting the deflaker, adjust the gap between the fixed plate and the moving plate to 0.40mm-0.50mm, and the speed to 900r / min. After keeping it for 2min, adjust the gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com