Sandwich screen cloth for composite plate

A composite sheet and sandwich technology, which is applied in the direction of synthetic resin layered products, conjugated synthetic polymer artificial filaments, layered products, etc., can solve the problems of poor high temperature resistance and achieve enhanced hairy feel and excellent impact resistance Sexuality, the effect of fabric composite firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

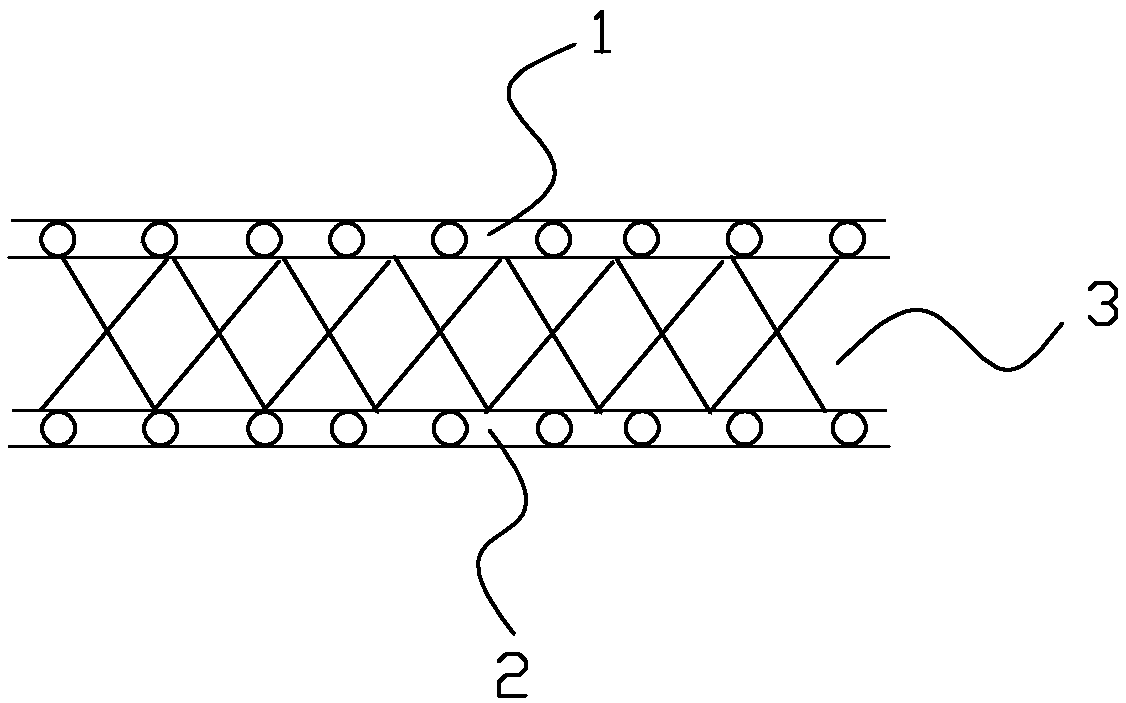

[0030] refer to figure 1 , a sandwich mesh for composite panels, consisting of a surface layer 1, a bottom layer 2 and a support yarn 3 connected between them; the surface layer 1, bottom layer 2 and support yarn 3 are woven into a three-dimensional sandwich by warp knitting Mesh, warp knitting has better dimensional stability than weft knitting, and is not easily deformed; the surface layer 1 is woven into a parallel structure with heat-resistant spandex fibers and carbon fibers; the bottom layer 2 is woven into a parallel structure with polyester fibers; The support yarn 3 is woven from heat-resistant spandex fiber monofilament, the surface layer 1 and the bottom layer 2 are all woven with meshes, and its shape is circular; The local weft insertion weave with a long pitch ensures the vertical and horizontal stability of the fabric, even under high temperature conditions without deformation or shedding. The heat-resistant spandex fiber has both the high elasticity and ultrav...

Embodiment 2

[0035] A sandwich mesh for composite boards, consisting of a surface layer 1, a bottom layer 2, and a supporting yarn 3 connected between them; the surface layer 1, the bottom layer 2, and the supporting yarn 3 are woven into a three-dimensional sandwich mesh by warp knitting Cloth, warp knitting has better dimensional stability than weft knitting, and is not easily deformed; the surface layer 1 is woven into a parallel structure by heat-resistant spandex fibers and carbon fibers; the bottom layer 2 is woven into a parallel structure by polyester fibers; The supporting yarn 3 is woven from heat-resistant spandex fiber monofilament, and the surface layer 1 and the bottom layer 2 are both woven with meshes, and its shape is square.

[0036] The technological process of the manufacturing method of the three-layer mesh mainly includes the following steps: warping, shafting, yarn threading, weaving, gray cloth, inspection, storage, warehouse delivery, cylinder matching, seam head, b...

Embodiment 3

[0040] A sandwich mesh cloth for composite panels, which is composed of a surface layer 1, a bottom layer 2 and a support yarn 3 connected therebetween; the surface layer 1, bottom layer 2 and support yarn 3 are woven into a three-dimensional sandwich mesh by warp knitting Cloth, warp knitting has better dimensional stability than weft knitting, and is not easily deformed; the surface layer 1 is woven into a parallel structure with heat-resistant spandex fibers and carbon fibers; the bottom layer 2 is woven into a parallel structure with polyester fibers; The support yarn 3 is woven into monofilament of heat-resistant spandex fiber, and the surface layer 1 and the bottom layer 2 are both woven with meshes, and its shape is square.

[0041] The technological process of the manufacturing method of the three-layer mesh mainly includes the following steps: warping, shafting, yarn threading, weaving, gray cloth, inspection, storage, warehouse delivery, cylinder matching, seam head, bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com